Explore how AI, IoT, and automation strengthen modern JIT management while addressing challenges related to supplier reliability and uncertain demand.

As global supply chains become more interconnected, they become more fragile. In this context, successful just-in-time (JIT) strategies require more than traditional lean practices. They now need digital technologies capable of sensing, predicting, and adapting to change in real time.

That’s why artificial intelligence, IoT connectivity, and automated workflows have suddenly become a powerful catalyst for JIT.

However, organizations still grapple with supplier unpredictability, volatile demand patterns, and cultural resistance that impede the adoption of these new tools. With Autodesk, manufacturers can integrate these new technologies without threatening their existing workflows.

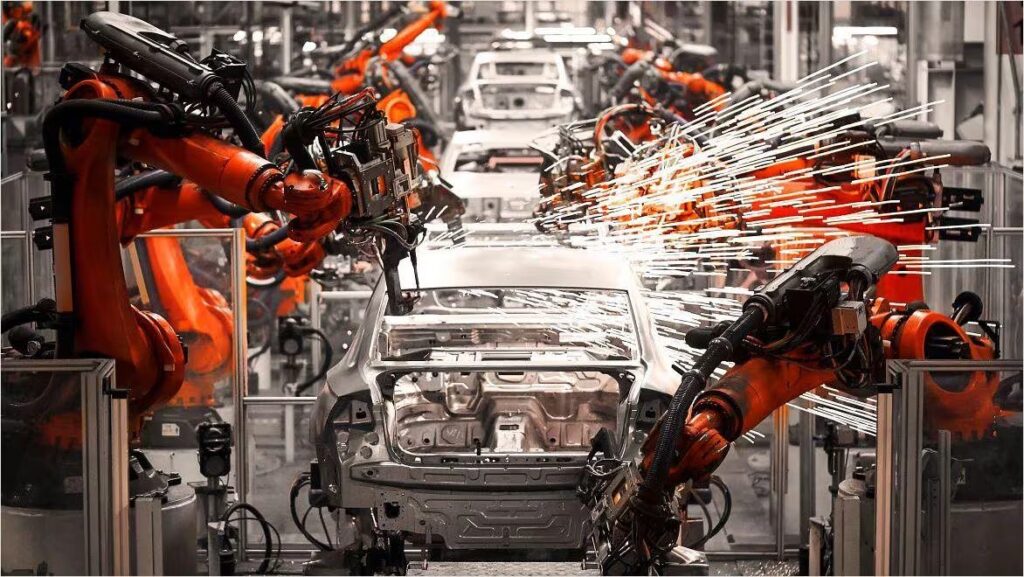

Technology-driven JIT in the modern supply chain

Today’s supply chains are rife with uncertainty. Supplier lead times can swing with geopolitical shifts, logistics bottlenecks can occur unexpectedly, and materials availability might change overnight. These pressures expose the traditional vulnerability of JIT management: a disruption at any upstream point threatens the entire production cadence.

Fortunately, new technologies are helping mitigate those risks.

- IoT: Connected systems push visibility beyond the plant floor by aggregating data on material, machine, and environmental conditions. With more transparency, manufacturers can more quickly detect discrepancies that would otherwise pass unnoticed and culminate in supply shortages or production delays.

- AI: Artificial intelligence turns raw operational data into predictive insight. Machine learning models use historical demand and sensor readings to better anticipate fluctuations in customer orders or supplier performance. With AI, JIT can reduce the strain volatility causes.

- Automation: New technologies in automation eliminate common JIT bottlenecks by executing repetitive tasks. When paired with AI, automation enables more adaptive, efficient workflows.

Naturally, sustainability goals are also front and center. JIT management has always reduced waste by limiting excess inventory, but modern implementations with new technologies also consider energy use, transport, and material utilization. For example, predictive insights through AI can minimize unnecessary machine movement and energy expenditure. Digital modeling and automated scheduling help companies avoid overproduction and prevent materials from expiring in storage.

Even with these advantages, cultural change is a hurdle. Adopting new technologies requires trust in data and systems, and leadership that frames digital JIT management as a move toward more informed decision-making, rather than a loss of control.

Advancing JIT management with Autodesk

As new technologies continue to influence JIT practices, Autodesk offers solutions to embrace change.

Autodesk Factory Design Utilities helps teams model factory environments digitally, creating precise layouts that let engineers test JIT-driven material flow before physical changes occur. Specifically, the tool’s 3D modeling capabilities let teams visualize optimized workflows and identify inefficiencies ahead of implementation. With digital layouts, energy consumption, travel distances, and material handling paths can be evaluated early. This also benefits sustainability efforts.

Fusion Operations: Manufacturing Insights at Your Fingertips

Fusion Operations provides real-time data to optimize scheduling, inventory, and quality.

Fusion Operations supports JIT by providing a cloud-based production management system that connects your shop floor with your planning tools. It enables dynamic scheduling, real-time inventory tracking, and automated work order updates, ensuring materials and resources are available exactly when needed—no sooner, no later. By reducing bottlenecks and improving communication between teams, Fusion Operations helps minimize waste, lower carrying costs, and keep production agile to meet fluctuating demand.

New tech for better manufacturing

Modern JIT is experiencing a significant boost from technologies such as AI, IoT, and automation. However, meaningful success and adoption will hinge on cultivating organizational trust in these new tools and rethinking traditional operating habits.

Autodesk Factory Design Utilities and Vault strengthen JIT management by offering the spatial intelligence and controlled data environment needed to support reliable, flexible, and environmentally responsible production. Together, they help manufacturers advance toward a more adaptive and sustainable future.