& Construction

Integrated BIM tools, including Revit, AutoCAD and Civil 3D

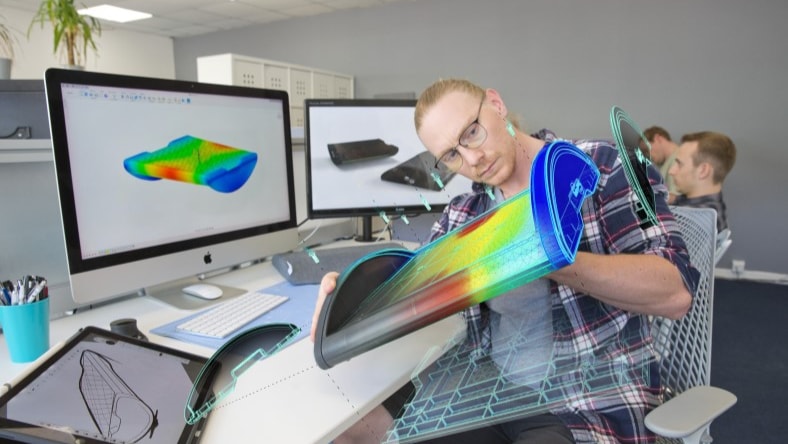

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

The Autodesk ASEAN Innovation Awards 2024 is an annual skills-based competition that honors and celebrates projects and individuals within the ASEAN region who are at the forefront of embracing the future of making through innovative technology.

These include applying Building Information Modeling (BIM) and Autodesk Architecture, Engineering, and Construction (AEC) solutions, Autodesk Construction Cloud solutions, and the use of advanced features of Autodesk Design and Manufacturing solutions like 3D modelling, simulations, and collaboration tools to optimize product development cycles, enhance quality control, and bring products to market faster than ever before.

Submissions open from April 15 - July 7

April 15 - July 7

July 8 - 31

August 26

Category

This award recognizes companies who embraced Digital Transformation with the use of BIM for an end-to-end project delivery, by improving overall productivity, project workflow with the help of technology.

Category

This award recognizes companies who embraced digital technologies and integrated cloud workflows for an end-to-end digital project delivery.

Category

This award recognizes companies who have implemented sustainability initiatives (Green Sustainability, Generative Design, and DfMA) to minimize environmental impacts such as energy/ water efficiency, environmental protection and indoor environmental quality etc.

Category

This award recognizes academia involved in nurturing students in digital construction to build the future pillars.

Category

This award recognizes organizations employing Autodesk solutions to enhance scope and productivity of business processes, succeeding through a unique approach and innovative use of technology to design, build & create.

Category

This award recognizes teams that disrupt the status quo by modernizing what it means to be an industry leader in creating technological breakthroughs for others to emulate.

Category

This award recognizes academia involved in nurturing students in digital construction to build the future pillars.

All entries need to be submitted before July 7, 2024 at 11:59PM (GMT+08:00), winners will be selected based on top submissions for each category in each country. One winner for each category for ASEAN will be selected from the top entries from each country. Winner announcement on August 26, 2024. Expand and read the detailed T&Cs below:

Program Description

The Autodesk ASEAN Innovation Awards (the “Innovation Awards ", “Competition”, “Contest”, or “Promotion”) is a skill-based competition presented by Autodesk Asia Pte. Ltd. (the “Sponsor”) that honors and celebrates projects and people within ASEAN region who are at the forefront of embracing the future of making through innovative technology. These include applying Building Information Modeling (BIM) and Autodesk Architecture, Engineering, and Construction (AEC) solutions, Autodesk Construction Cloud solutions, and the use of advanced features of Autodesk Design and Manufacturing solutions like 3D modelling, simulations, and collaboration tools to optimize product development cycles, enhance quality control, and bring products to market faster than ever before.

The category award titles as follows:

Projects may be submitted for consideration by completing an Official Entry Form (the “Project Entry”) at https://www.autodesk.com/asean/campaigns/asean-innovation-awards-2024. (the “Contest Site”). The person designated as the team leader on the Project Entry must be a representative of the Organization/Firm named on the Project Entry and must have the authority to represent and bind the Organization/Firm with respect to the Project Entry, and will be referred to herein as the “Entrant” or “Team Leader.” All Entrants are subject to the conditions and limitations on eligibility set forth in these Official Rules.

Winners will be announced in the Autodesk ASEAN Innovation Award ceremony in Malaysia on August 26, 2024 and published on Autodesk ASEAN Facebook page at https://www.facebook.com/AutodeskASEAN/ by September 9, 2024.

Program Timing

Entry submission into the Contest begins at 12:00:01 AM (GMT+08:00) on April 15, 2024 and ends July 7, 2024 at 11:59PM (GMT+08:00) (the “Entry Period”). The Administrator’s clock is the official timekeeping device for this Contest. There are a series of Contest-related events that will start and end on or about the dates noted in the events calendar below:

Program Process

Beginning April 15, 2024, visit the registration page and follow the instructions to secure your contest spot. Once you have submitted your particulars, you may start a Project Entry. All Project Entries must be submitted via the official email and received by 11:59:59 PM (GMT+08:00) on July 7, 2024 . All Project Entries must comply with all Requirements, Conditions of Entry, and the instructions set forth on the Contest Site (which are incorporated herein by reference). Determination of compliance will be at the sole discretion of the Sponsor/Judges/Administrator, whose decisions are final. Entrants may submit multiple Project Entries as long as it meets the category’s requirements; however, a Project Entry can only win once.

Project Entry Requirements:

Each Project Entry must be complete and contain all required supporting information and Contest details, along with Project imagery/renderings/ photographs. Videos of the Project are encouraged but not required.

Imagery and Videos must adhere to the following requirements:

Autodesk Product Requirements:

For Architecture, Engineering & Construction submission

The Project submitted must be created with at least one of the following Autodesk® software products and/or Autodesk® accepted previous versions of these products: Assemble, Autodesk® 3ds Max®, Autodesk® Advance Steel, Autodesk® AEC Collection, Autodesk® AutoCAD®, AutoCAD Architecture, AutoCAD Electrical, AutoCAD Map 3D, AutoCAD Mechanical, AutoCAD MEP, AutoCAD Plant 3D, AutoCAD Raster Design, AutoCAD mobile app, and AutoCAD web app, Autodesk® BIM 360® Build, Autodesk® BIM 360® Coordinate, Autodesk® BIM 360® Cost Management, Autodesk® BIM 360® Design, Autodesk® BIM 360® Docs, Autodesk® BIM 360® Field, Autodesk® BIM 360® Glue®, Autodesk® BIM 360® Layout, Autodesk® BIM 360® Ops, Autodesk® BIM 360® Plan, Autodesk® Build, Autodesk® Docs, Autodesk® BIM Collaborate, Autodesk® BIM Collaborate Pro, Autodesk® Takeoff, Autodesk® Civil 3D®, Autodesk® Dynamo Studio or Dynamo for Revit®, Autodesk® Fabrication Came™, Autodesk® Fabrication CAMduct™, Autodesk® Fabrication ESTmep™, Autodesk® FormIt, Autodesk® InfraWorks®, Autodesk® Insight™, Autodesk® Navisworks® Manage, Autodesk® Navisworks® Simulate, Autodesk® ReCap™ Pro, Autodesk® Rendering, Autodesk® Revit LT®, Autodesk® Revit®, Autodesk® Revit® Live, Autodesk® Robot™ Structural Analysis Professional, Autodesk® Structural Bridge Design, Autodesk® Vehicle Tracking, PlanGrid.

For Design & Manufacturing submission

The Project submitted must be created with at least one of the following Autodesk® software products and/or Autodesk® accepted previous versions of these products: Alias Concept, Alias SpeedForm, Alias Surface, ArtCAM - Premium, Autodesk AutoCAD ECSCAD, Autodesk CFD Design Study Environment, Autodesk Configure One - Advanced Small Team, Autodesk Configure One - Premium Connection, Autodesk Configure One - Standard Connection, Autodesk Configure One - Starter Small Team, Autodesk Moldflow Design Link for CATIA V5, Autodesk Moldflow Design Link for Parasolid, Autodesk Nastran, Autodesk Sim 360 Pro, CADdoctor for Simulation, Configurator 360 - Standard, Factory Design Suite Premium, FeatureCAM - Standard, FeatureCAM - Ultimate, Flow Design, Fusion 360 Team - Participant, Fusion 360 with EAGLE Premium, Fusion 360 with EAGLE Stndr, Helius Composite, Helius PFA, HSM - Premium, HSMWorks, HSMWorks - Premium, Inventor CAM Express, Manufacturing Post Processor Utility, Moldflow Design, Moldflow Synergy - Token Flex, Netfabb Local Simulation, Post Processor - Premium, Post Processor - Ultimate, PowerInspect - Standard, PowerInspect - Ultimate, PowerMill - Ultimate, PowerShape - Standard, TruNest Composites, VRED, Nesting Utility, Autodesk Alias Studio, Autodesk AutoCAD Utility Design, Autodesk Inventor CAM - Premium, Autodesk Inventor CAM - Ultimate, Intent Professional, Inventor Engineer-to-Order Series, Alias Automotive, Alias AutoStudio, Alias Design, ArtCAM - Standard, AutoCAD Electrical, AutoCAD Inventor LT Suite, AutoCAD Mechanical, Autodesk Algor Simulation, Autodesk CFD, Autodesk CFD - Ultimate, Autodesk Configure One - Advanced Large Team, Autodesk Configure One - Advanced Unlimited Team, Autodesk Configure One - CADD Add On, Autodesk Configure One - Connect for SAP, Autodesk Configure One - Connect for SAP Advanced, Autodesk Configure One - Consulting, Autodesk Configure One - Enterprise Large Team, Autodesk Configure One - Enterprise Small Team, Autodesk Configure One - Enterprise Unlimited Team, Autodesk Configure One - SandBox Add On, Autodesk Direct Connect - CAT, Autodesk Inventor Publisher, Autodesk Moldflow Adviser Standard, Autodesk Moldflow Design Link for Pro/ENGINEER, Autodesk Nastran In-CAD, Autodesk Navisworks Manufacturing Manage, Autodesk Navisworks Manufacturing Review, Autodesk Navisworks Manufacturing Simulate, Autodesk Productstream, Autodesk Simulation Mechanical 360, Autodesk Simulation Multiphysics, Autodesk SketchBook Designer, CFD - Premium, Factory Design Suite Standard, Factory Design Suite Ultimate, Factory design Utilities, FeatureCAM - Premium, Fusion 360, Fusion Connect Advanced, Fusion Connect Enterprise, Fusion Connect Starter, Fusion Production, Fusion Team - Single User, HSM - Ultimate, HSMWorks - Ultimate, HSMxpress, Inventor LT, Inventor Professional, Inventor Tolerance Analysis, Manufacturing Automation Utility, Manufacturing Data Exchange Utility - Premium, Manufacturing Data Exchange Utility - Standard, Moldflow Insight - Ultimate Token Flex, Moldflow Insight Premium, Moldflow Insight Standard, Moldflow Insight Ultimate, Moldflow Synergy, Netfabb - Premium, Netfabb - Ultimate, PowerInspect - Premium, PowerMill - Premium, PowerMill - Standard, PowerShape - Premium, PowerShape - Ultimate, Product Design & Manufacturing Collection, Product Design Suite Premium, Product Design Suite Standard, Product Design Suite Ultimate, Showcase, SimStudio Tools, Simulation Mechanical, Studio Wall, Substation Design for AutoCAD Electrical, Substation Design for Inventor, TruComp, TruFiber, TruLaser, TruNest, TruNest Contour, TruPlan, Vault Professional, Vault Workgroup, VRED Design, VRED Professional, Autodesk Within, Within Medical, Fusion 360 - with Cloud Credits, CFD - cloud service entitlement, Configurator 360 - Unlimited Configurations, Enterprise Add-on for Vault, Inventor ETO - Developer, Inventor ETO - Distribution, Inventor ETO - Server, Inventor OEM, Jitterbit Enterprise, Jitterbit Professional, Jitterbit Standard, Moldflow - cloud service entitlement, Moldflow Adviser Premium, Moldflow Adviser Ultimate, Simulation Enterprise cloud credits, TruComposites - Standard, TruComposites - Ultimate, Vault Basic - Client, Vault Basic - Server, Vault File Server, Vault Office, Vault Professional Client, Vault Workgroup Client, VRED Presenter, VRED Render Node, VRED Server, Sketchbook, Alias TC Integrator for GM, Autodesk Moldflow Communicator, Fusion 360 - Ultimate, Fusion 360 - with FeatureCAM, Fusion 360 - with FeatureCAM Standard, Intent, Intent AC, Intent AC Solids, Intent Developer, Intent Runtime, Inventor Mold, Inventor Runtime, Manufacturing Extension for Fusion 360, Moldflow Plastics Insight - Fusion + 3D, Moldflow Structural Alliance, Productstream Professional Easy, TruNest Multi-Tool, TruPost, Vault PLM - Enterprise, Vault PLM - Professional, Premium, Fusion Lifecycle - Enterprise - daily metering, Fusion 360 with PowerMill Standard, Fusion 360 with PowerMill Ultimate, Fusion 360 with PowerShape, Fusion 360 with PowerInspect, Vault Office - for Vault Workgroup users, Fusion 360 - Generative Design Extension, Fusion 360 - Additive Build Extension, Fusion 360 - Machining Extension, Fusion 360 - Additive Build Extension - Flex Access, Fusion 360 with Netfabb Premium, Fusion 360 with Netfabb Ultimate, Fusion 360 - Nesting & Fabrication Extension, Fusion 360 - Manage Extension, CAMplete TruePath, CAMplete TruePath - legacy user, CAMplete TurnMill, CAMplete TurnMill - legacy user, Fusion 360 with Netfabb Standard, Fusion 360 Manage - Enterprise, Fusion 360 Manage - Participant, Fusion 360 Manage - Pro, Fusion 360 Manage - for third-party users, Fusion 360 Manage - sandbox, Upchain, Upchain Professional, Upchain Participant, Upchain Team, Fusion 360 - Product Design Extension, Fusion 360 - Simulation Extension, Fusion 360 - Machining Extension - Legacy Offer, Fusion 360 for Product Design, Fusion 360 for Manufacturing, VRED Learning Edition, Alias Learning Edition, ProdSmart, Fusion 360 with Moldflow Adviser, Moldflow Insight, Fusion 360 with Moldflow Adviser - Legacy, Moldflow Insight - Legacy, Fusion 360 Manage with Upchain - Enterprise, Fusion 360 Manage with Upchain - Participant, Fusion 360 Manage with Upchain - Pro, Fusion 360 Manage with Upchain - Sandbox, Fusion 360 Manage with Upchain - Standard, Fusion 360 - Signal Integrity extension

The Competition is open to Firms who are users of Autodesk software and work within the Architecture-Engineering-Construction (AEC) and Design and Manufacturing (D&M) industry sectors. Entrant’s respective Firm and Nominees must be domiciled in one of the following countries: Indonesia, Malaysia, Philippines, Thailand, Singapore, or Vietnam; and must have a commercial license for the requisite Autodesk software for their Project Entry prior to July 1, 2024. Entrant must have the authority to represent and bind the Organization/Firm named on the Project Entry. Entrant/Team Members/Nominees must be at least 18 years of age (and age of majority in their jurisdiction of residence). Void where prohibited or restricted by law. Autodesk Inc., the Co-Sponsors, Judges, Channel Partners, their affiliates, subsidiaries, promotion agencies, (collectively “Released Parties”) and their immediate family members and/or those living in the same household of each (whether related or not) are not eligible. For purposes of this Contest, the term “family member” is defined as spouse, partner, parent, legal guardian, in-law, grandparent, child, or grandchild. Also, ineligible to participate are any parties who are under any obligation, contractual or otherwise, that would prohibit the Entrant and/or Nominee from accepting a Prize/Award. Projects nominees that have previously won an AEC Excellence Award are not eligible to win in this Contest. Students are ineligible to participate in this Contest.

Sponsor or Administrator reserves the right to disqualify any Project Entry for any reason, in its sole and absolute discretion, including the determination that a Project Entry fails to satisfy any of the Project Entry Requirements, Conditions of Entry, or is inconsistent with the goals, image, or policies of the Sponsor or Administrator. Any Project Entry not submitted in accordance with the instructions provided on the Contest Site (which are incorporated herein by reference) shall not be considered for the Contest, and none of the Released Parties shall bear any responsibility for any such invalid/incomplete entries.

Project Entries: Eligible Project Entries received will be judged by a pre-determined panel of industry judges to determine the top 6 Project Entry in each country. Judging will be based on the judging criteria, as outlined below (“Judging Criteria”). The Project Entry with the highest score in each country will be deemed as the country award winner for each respective award title and compete for the grand title for each category.

Judging Criteria for Architecture, Engineering & Construction submission

Category

|

Judging Criteria |

|---|---|

| Innovator of The Year Award |

|

| Cloud Advocate of The Year Award |

|

Better World Builder of The Year Award |

|

| Future Pillar of The Year Award |

|

Judging Criteria for Design & Manufacturing submission

Category

|

Judging Criteria |

|---|---|

Digital Innovation of The Year Award & Industry Disruptor of The Year Award

|

|

| Future Pillar of The Year Award |

|

In the event of a tie at any point during the judging process, a judge determined by the Administrator in its sole discretion will evaluate the tied Entries based on the respective Judging Criteria to break the tie. The Panel of Judges' decisions is final and binding on all matters relating to the Contest.

Notification & Verification Process

Winners will be announced in the Autodesk ASEAN Innovation Award ceremony in Malaysia on August 26, 2024 and published on Autodesk ASEAN Facebook page at https://www.facebook.com/AutodeskASEAN/ by September 9, 2024.

Winners will also be notified via email. The Entrant named on the winning Project Entry will be required to sign and return to Administrator within seven (7) days of notification an Affidavit of Eligibility/Liability Release and where legal, Publicity Release. Remaining Project Entries may be required to provide additional documentation to validate eligibility and/or execute additional documentation with regards to the use of the Entry materials, at the Administrator sole discretion. If it is determined that any Entry has not complied with these Official Rules, Administrator is unable to contact a potential Winner within a reasonable time period, potential Winner has failed to properly execute and return any required documents within the specified time period, or has made false statements, or if a potential Winner declines the prize, then such Entry will be disqualified and the Finalist with the next highest-scoring Entry will be notified, time permitting. Administrator/Sponsor reserves the right to disqualify any potential Winner/Finalist at any time, in their sole discretion, in the event circumstances arise that would constitute a breach of these Official Rules or otherwise.

Prizes / Awards

The contest prize is provided by Autodesk on “as is” basis and shall be governed by the applicable agreement from the Sponsors. Receivers shall take sole responsibility for determining, obtaining and complying with all third-party terms. Autodesk will have no responsibility for and makes no representations and warranties regarding any third-party products and/or services.

If the customer is an organization, the prize (or award) is provided to the organization, instead of the individual persons of the customer. The individual employee is accepting the prize in accordance with their employer’s policy. Handling the importation and associated duty / taxes / individual income tax (if any) or other charges will be borne by the receiver.

Determination of the Winners by the panel of Judges and prizes thereof are final. No queries will be entertained.

The Entrant will retain ownership of all intellectual and industry property rights in all materials submitted to the Contest. However, by submitting an Entry, Entrant waives all rights that may preclude Sponsor or Administrator from using Entry and related materials or information. Submission of an Entry grants Sponsor or Administrator and its agencies, to the extent allowed by law, the irrevocable right to use, publish, adapt, assign, edit, dispose of, and/or modify such Entry and the concepts embodied therein in any way, in commerce and in any and all media worldwide, without limitation or compensation to the Entrant or his/her affiliated Organization/Firm. By submitting an Entry and/or accepting a prize/award, Entrant/winner gives permission for the Sponsor or Administrator and its designees to use the Entrant’s/winner’s name, voice, actual or simulated likeness, Entry and biographical information along with the names of the entities named on their Entry (including, without limitation, for advertising and promotional purposes) in perpetuity, throughout the universe, in all media whether now known or hereafter devised, without further review, notice, approval or compensation unless prohibited by law.

General conditions & limitations of liability

Entrants and Nominators producing and submitting materials for consideration in this Contest will do so without compensation and at their own risk. By entering, all participants, including but not limited to each Entrant, Nominator, Nominee, and other participants named as a Team Member/collaborator on an Entry, release, discharge, and hold harmless Released Parties from any and all liability or any injuries, loss or damage of any kind (including damages caused or claimed to be caused) arising from or in connection with this Contest, the use of any Contest Entry, or the acceptance or use of any Prize/Award. Released Parties are not responsible or liable for any of the following: (a) Electronic transmissions, Entries that are late, incomplete, inaudible, illegible, damaged, garbled, destroyed, misdirected, or not received by Sponsor or its agents for any reason; (b) Any problems or technical malfunctions, errors, omissions, interruptions, deletions, defects, delays in operation or transmission, communication failures, and/or human error that may occur in the transmission, receipt or processing of Entries or related materials; or for destruction of or unauthorized access to, or alteration of, Entries or related material; (c) Failed or unavailable hardware, network, software, or telephone transmissions, damage to any person’s computer and/or its contents related to or resulting from participation in this Contest, or (d) Causes beyond Sponsor’s reasonable control that jeopardize the administration, security, fairness, integrity, or proper conduct of this Contest; (e) Any printing errors in these Official Rules, the Contest Site, or in any advertisements, materials, or correspondence in connection with this Contest; or (f) any copyright, trademark, patent, trade secret, or other intellectual property misappropriation or infringement attributable to Entrant/Nominator/Nominee or any entry submitted by Entrant or Nominator. Sponsor reserves the right, in its sole discretion, to cancel, modify, or suspend this Contest should virus, bugs, fraud, hacking, or if technical difficulties compromise the integrity of the Contest, or if other causes beyond the control of the Sponsor corrupt the administration of security of the Contest. In such cases, notice to this effect will be posted on the Contest Site and the eligible Entries received prior to cancellation, modification, or suspension or as otherwise deemed fair and appropriate by Sponsor will be judged to determine Winners. CAUTION: ANY ATTEMPT TO DELIBERATELY DAMAGE ANY WEB SITE OR UNDERMINE THE LEGITIMATE OPERATION OF THE CONTEST IS A VIOLATION OF CRIMINAL AND CIVIL LAWS AND SHOULD SUCH AN ATTEMPT BE MADE, SPONSOR RESERVES THE RIGHT TO SEEK DAMAGES OR OTHER REMEDIES FROM ANY SUCH PERSON(S) RESPONSIBLE FOR THE ATTEMPT TO THE FULLEST EXTENT PERMITTED BY LAW.

AUTODESK RESERVES THE RIGHT TO CANCEL, SUSPEND OR MODIFY PART OF THIS ENTIRE CONTEST AT ANY TIME WITHOUT NOTICE, FOR ANY REASON IN ITS SOLE DICRETION.

All federal, state, provincial, and local laws and regulations apply. All submitted information is subject to verification. Sponsor may assign, delegate, subcontract, or transfer any of its rights or obligations hereunder and may authorize any direct or indirect affiliate of Sponsor to act as Sponsor’s agent for purposes of this Agreement, including fulfillment of prizes. In the event of a dispute as to the identity of an Entrant, the Project Entry will be deemed to have been made by the registered account holder of the e-mail address provided on the Project Entry Form. A registered account holder is defined as the natural person who is assigned to an e-mail address by an Internet access provider, online service provider, or other organization (e.g., business, educational institution, etc.) that is responsible for assigning e-mail addresses for the domain associated with the submitted e-mail address. If a dispute cannot be resolved to Sponsor’s satisfaction, the Entry in question may be disqualified in Sponsor’s sole discretion. By participating in this Contest, Entrants, Team Members, Nominators, and Nominees agree to be bound by the terms of these Official Rules.

Agreement to the following official rules

All federal, state, provincial, and local laws and regulations apply. All submitted information is subject to verification. Sponsor may assign, delegate, subcontract, or transfer any of its rights or obligations hereunder and may authorize any direct or indirect affiliate of Sponsor to act as Sponsor’s agent for purposes of this Agreement, including fulfillment of prizes. In the event of a dispute as to the identity of an Entrant, the Project Entry will be deemed to have been made by the registered account holder of the e-mail address provided on the Project Entry Form. A registered account holder is defined as the natural person who is assigned to an e-mail address by an Internet access provider, online service provider, or other organization (e.g., business, educational institution, etc.) that is responsible for assigning e-mail addresses for the domain associated with the submitted e-mail address. If a dispute cannot be resolved to Sponsor’s satisfaction, the Entry in question may be disqualified in Sponsor’s sole discretion. By participating in this Contest, Entrants, Team Members, Nominators, and Nominees agree to be bound by the terms of these Official Rules.

Governing Law/ Jurisdiction

Your personal information will be used in accordance with the Autodesk Privacy Statement and these Official Rules for the purposes of administering this Contest and in promotional and/or sales materials of Autodesk as described in the Contest Permission Form.

Miscellaneous

In the event of any conflict between the English version of these Official Rules and any translation, the English version shall prevail. The invalidity or unenforceability of any provision herein shall not affect in any way the validity and enforceability of any other provision in these Official Rules.