Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

.jpg)

Switching from Moldex3D for simulation accuracy

The ability to validate designs quickly and accurately can help minimize delays to the product design cycle. With over 10,000 lab-tested materials in the Moldflow database, any concerns over questioning your results are reduced. Additionally, the theoretical calculations behind the Moldflow solvers, are validated through development case studies and customer partnerships.

Mold processes in Moldflow vs. Moldex3D

Moldflow Insight Ultimate includes over 20 different molding process simulations, including thermoset and liquid silicone rubber (LSR) injection molding, co-injection molding, compression molding, gas-assisted injection molding (GAIM), and foam injection molding (chemical foaming and core-back).

Moldflow simulation flexibility

Local solve

Moldflow Adviser and Insight both include the local mesh and solve option to run local jobs with no need for internet connectivity.

Remote server

Moldflow Insight solvers can be installed on a seperate machine or server to free up local computers and provide the option of using parallelization, or parallel solver computing, for quicker solve times.

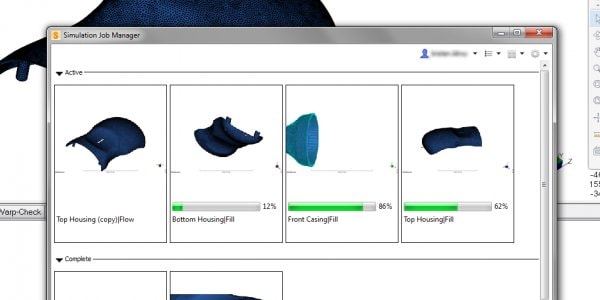

Cloud solve

Mesh and run multiple simulations in the cloud simultaneously, while you continue to work on other tasks on your computer. Cloud meshing and solving are hosted through the secure Amazon Web Services (AWS) platform.

Moldflow mold controller process optimization

A major influencer when manufacturing plastic parts is the process conditions. The design of experiments (DOE) and parametric design analysis in Moldflow help injection mold companies manufacture plastics with wide process windows to ensure stable part quality.

Moldflow plastic part quality visualization

Moldflow has built-in result and part quality visualization options and integrated export tools supporting post-processing of part and mold design for injection molded plastic parts.

-

Simple user interface (UI)

The Moldflow UI helps guide users through each step of the setup and result review, and enables customized panel creation to streamline common tasks.

-

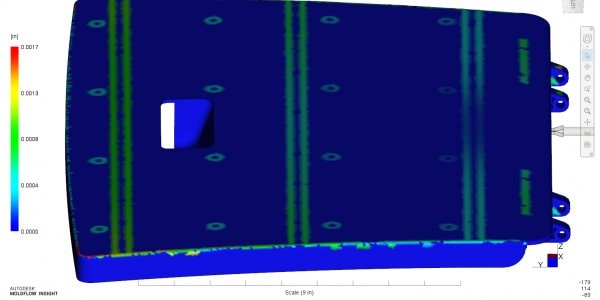

Sink mark export for visualization

Reviewing through in-product visualization allows design or process change decisions to be made quickly, while CAD and *.fbx export means presentation renderings can be produced.

-

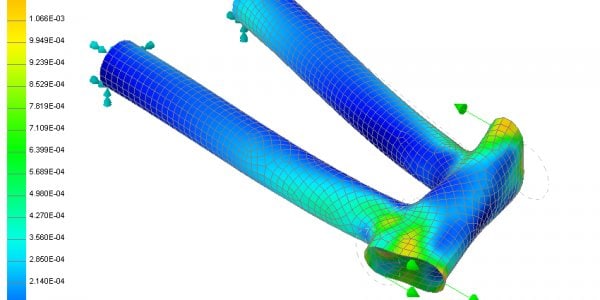

Export to finite element analysis (FEA)

Export models, material properties, and results, such as residual stresses, to FEA software to analyze the structural quality of as-molded plastic parts.

-

Advanced part & mold warpage prediction

Moldflow can isolate common causes of plastic part warp for analysts to identify the best approach to minimizing it.

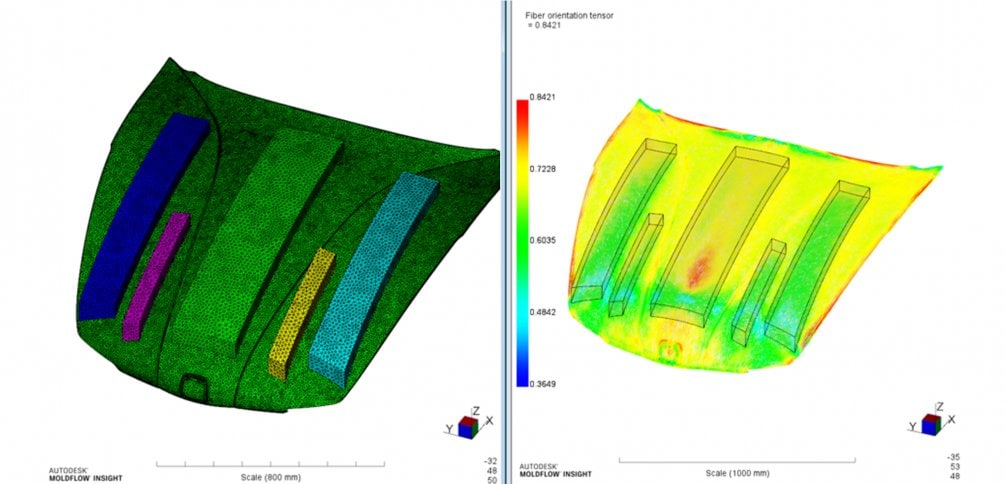

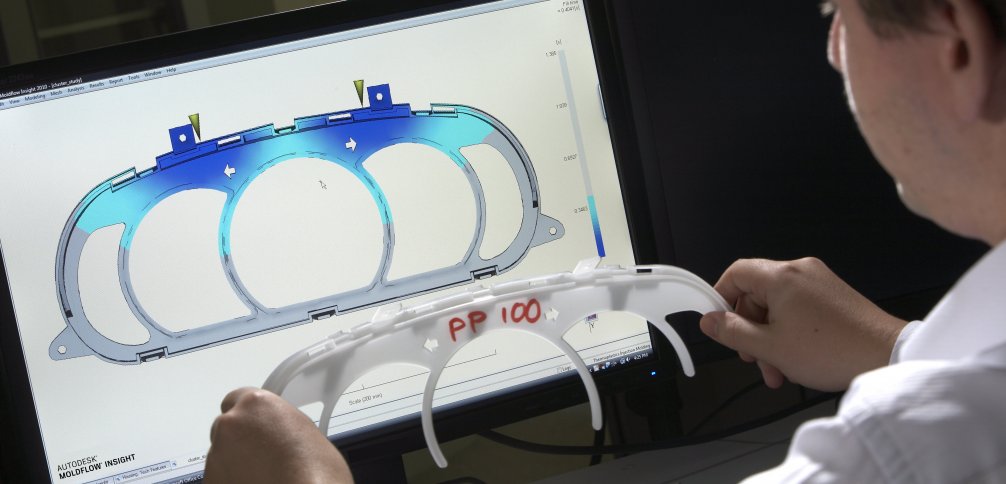

Moldflow for automotive lightweighting

Image courtesy of Celanese

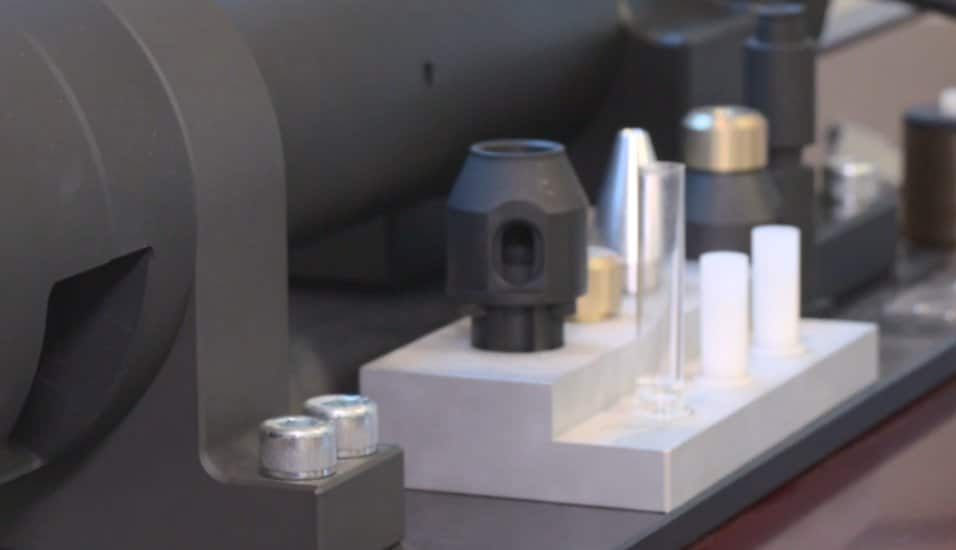

Moldflow for research & development

Image courtesy of JAKTOOL

Customer-centric Moldflow product development

The Moldflow software development team look to users for input on features they are developing through the use of periodic releasing of the Project Scandium, the technical preview for Moldflow Insight. It extends simulation capabilities for existing Moldflow subscribers by offering new capabilities, such as warpage analysis for assemblies and tiger striping prediction. The dedicated forum for feedback helps to direct the developers to where accuracy and workflow improvements can be made.

Have an Autodesk representative contact you

Call 1-855-612-9998 to speak with one of our Moldflow sales experts or fill in the form and we'll contact you.