Nick Neuhaus can’t remember a time when he wasn’t on two wheels. At the age of eight, he started racing BMX. He then took a long break from cycling to focus on racing motorcycles and building a career in telecommunications.

“Life has a way of pushing hobbies aside for a while,” Neuhaus says. “When I came back to bikes around 2015, the industry was really in a transitory period. The innovations since I’d last ridden eight years prior were exciting.”

But he couldn’t find his perfect “Goldilocks” fit, especially for mountain biking.

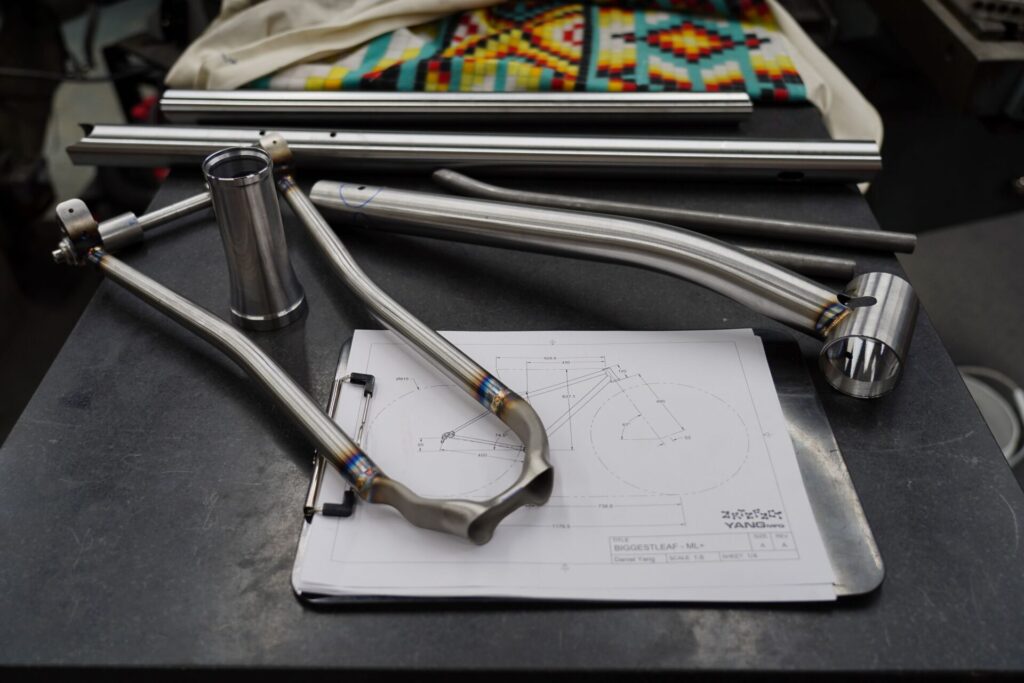

“I kept thinking that if I could combine all the bikes I loved into one, I’d have the perfect ride,” Neuhaus says. “But each one I tried was missing something. With a fabrication background and a small shop at home, I started making frames for myself and just casually for friends. Then Neuhaus Metalworks just grew from there.”

Neuhaus first met Daniel Yang, a designer and engineer, through a chance encounter when Yang was looking for his own custom bike frame. His background in mechanical engineering and 3D printing expertise provided a perfect fit to advance the company even further, and he joined the team. Now, Neuhaus Metalworks is a burgeoning business, moving from one-off custom frames to production bikes manufactured in Taiwan and a long line of custom orders

“Our combined backgrounds provided a catalyst to allow us to really grow the business at a fast rate, producing bikes both custom and now production that are widely loved by many,” Neuhaus says.

Bringing Autodesk Fusion into the mix

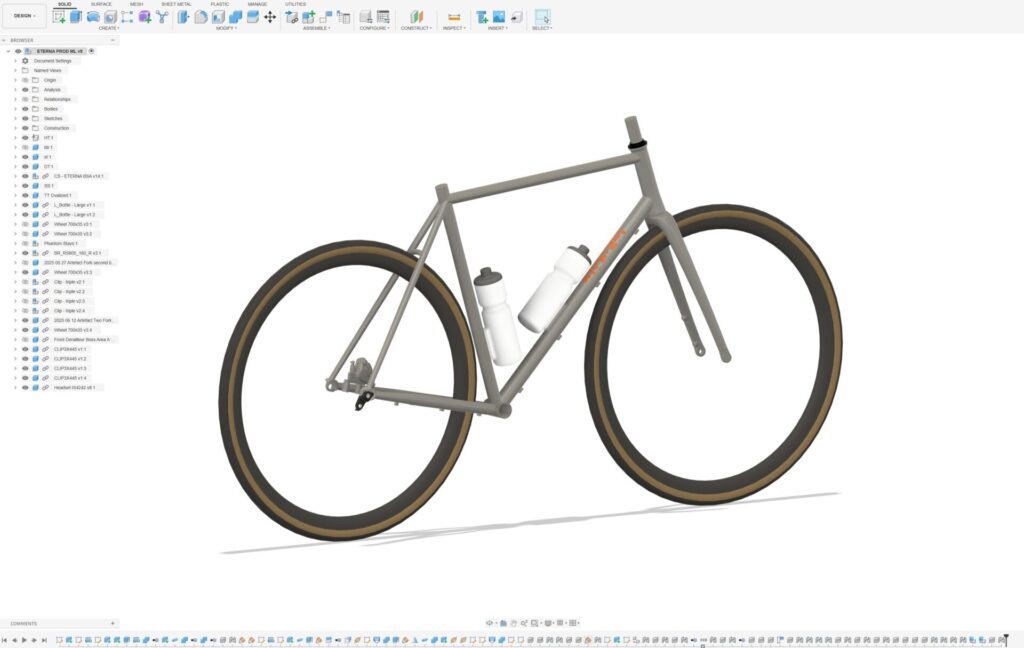

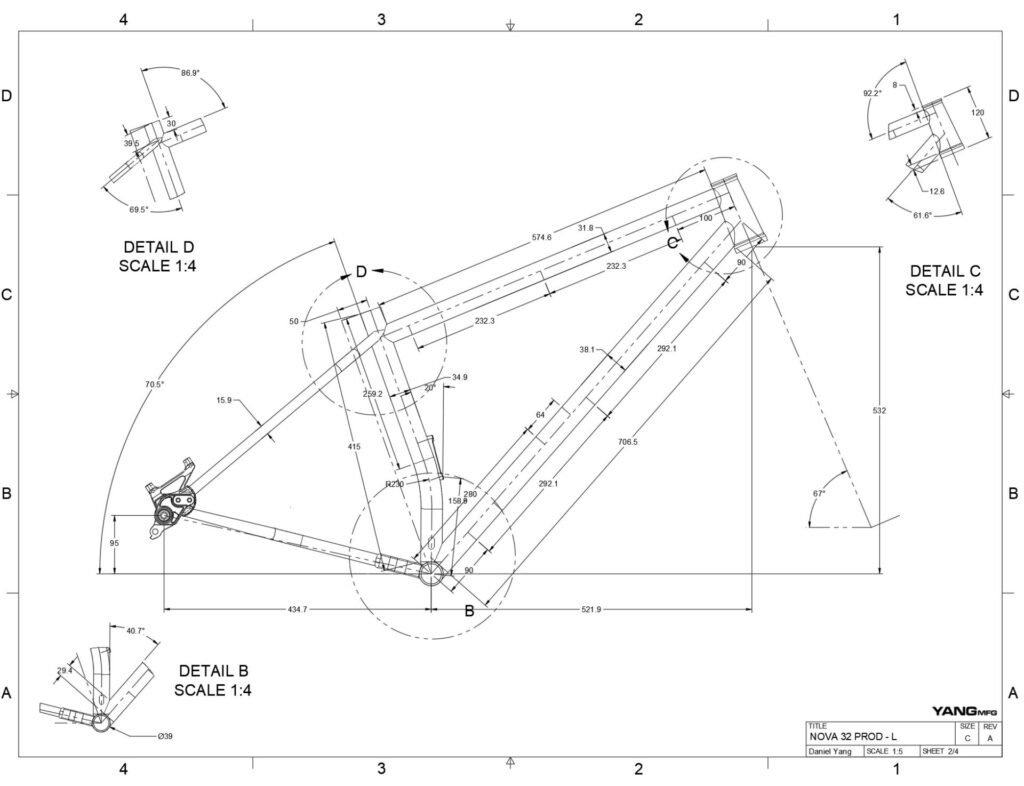

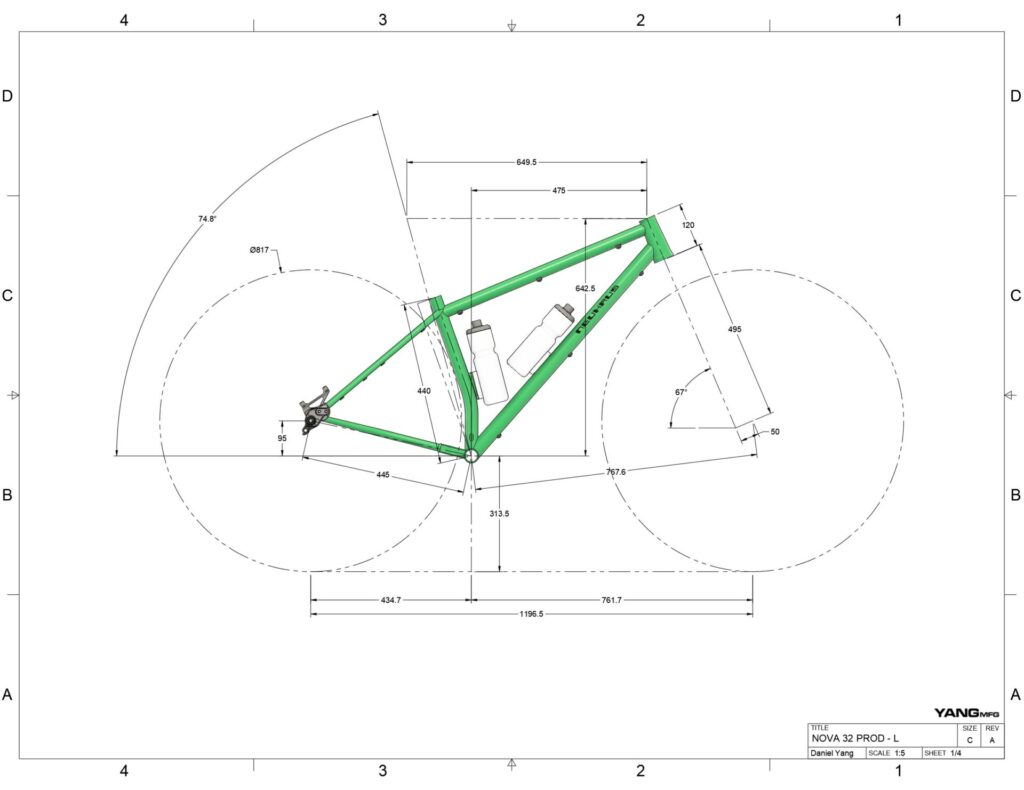

When Yang and Neuhaus teamed up, they started using Autodesk Fusion for their first frame called “Hummingbird.” Fusion’s price point, accessibility, and ease of use were key to developing their product line. Most frame builders design with basic 2D or even full paper templates, but the ability to take advantage of parametric modeling kick-started their transformation.

“Traditionally, as a frame builder, you need to figure things out in real life,” Neuhaus says. “You get the tubes and parts and then try to orient them to make them all work using your physical jigs and fixtures as reference. With Fusion and 3D models, we can look at all the clearance ahead of time. We don’t have to order a part and then later find out it doesn’t work.”

Early on, they started 3D printing parts to prototype and solve issues. Now, they are printing many of the parts for the bike itself as a business advantage.

“Using 3D printing for titanium parts solves many of our problems,” Yang says. “Fusion allows us to create impossible geometries that speed up the construction of our bikes.”

“A 5- or 6-axis CNC machine is not feasible for a business of our size and to make parts cost-effective,” Neuhaus adds. “Whereas with 3D printing, we do have that ability. We can print a single part, or we can print 10 parts. 3D printing really allows us to scale quickly because it streamlines our processes so much.”

Shifting the business into high gear

Neuhaus Metalworks provides custom, hand-built bikes in California with five different frame options. But it’s difficult to grow the business with a typical waitlist of three to five months for custom builds. They recently debuted the production frame “Hummingbird Core,” which is manufactured in Taiwan and is half the price of the custom frames. Two batches sold out within a couple of months, with new runs planned soon. They’re also designing several new production models for 2026.

According to Neuhaus and Yang, one of the biggest advantages of Fusion is Autodesk’s support of the Maker community. They have experienced it first-hand, growing from a passion project to a full-fledged business.

“It’s really powerful that there are other frame builders now who are using Fusion and didn’t come from an engineering background,” Yang says. “They can express their creativity and build a successful business. I think the business opportunity Fusion provides is its biggest strength.”

Yang is also taking new approaches to reach a wider audience with his popular YouTube channel. He’s committed to creating videos that help educate and inspire others to get on their bikes, highlight Neuhaus Metalworks’ development along with its sister company, “Artefact,” and learn more about the design process with Fusion.

“We want to be really open and share our work,” Yang says. “We plan on continuing to do what we’ve been doing, but even better.”