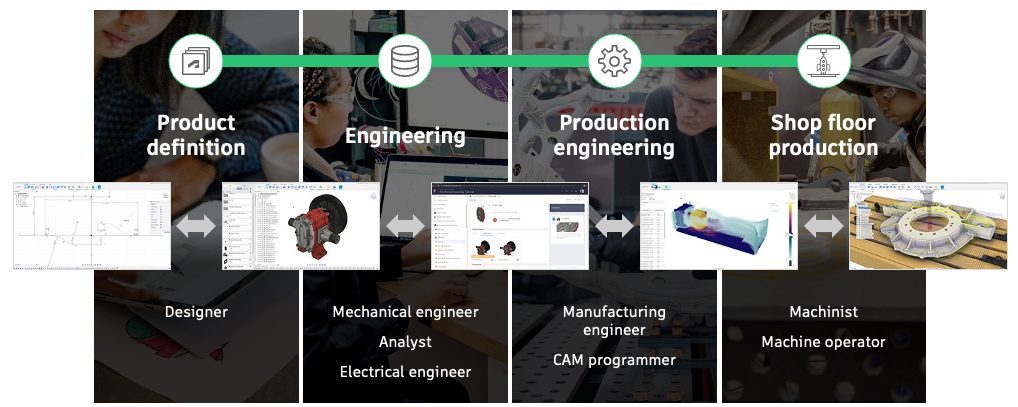

Discover the Autodesk Fusion 2026 roadmap and how AI, automation, and connected workflows are shaping the future of design and manufacturing.

As we move into 2026, we are building on the momentum of the past year and continuing to shape how data, design, and production come together. Our focus remains clear: give teams greater clarity, enable more seamless collaboration, and create the conditions for meaningful innovation.

The year ahead reflects steady progress. As Fusion matures, its capabilities deepen and the connections between workflows grow stronger, helping reduce the manual effort that once slowed teams down. The tools you rely on are becoming more capable and refined, supporting faster and more confident work across the design-to-production process. At the same time, we remain focused on strengthening the foundation behind that experience, delivering a robust and reliable environment you can depend on as your work becomes more ambitious and demanding.

Here’s how those priorities take shape across Fusion in the year ahead.

Table of Contents

- Disclaimer: Safe Harbor Statement

- AI and Automation

- Data Management

- Design

- Performance and Stability

- Electronics

- Manufacturing

- Help us shape the future of Fusion

Disclaimer: Safe Harbor Statement

During the course of this communication, we may make forward-looking statements regarding future events and future performance. These forward-looking statements are subject to assumptions, risks, and uncertainties, which are discussed in documents we file from time to time with the SEC and specifically in our Annual Report and 10-K filed for the most recently completed year-end. These documents contain and identify important factors that may cause the actual results to differ from those contained in our forward-looking statements.

Additionally, we may make statements regarding planned or future development efforts for our existing or new products and services. These statements are not intended to be a promise or guarantee of future delivery of products, services, or features but merely reflect our current plans, which may change. Purchasing decisions should not be made based upon reliance on these statements.

Autodesk assumes no obligation to update these forward-looking statements to reflect events that occur or circumstances that exist or change after the date on which they were made.

AI and Automation

At AU 2025, we shared our vision for how artificial intelligence will shape the future of design and make, and Autodesk Assistant represents an important step along that path. Built on years of AI research and developed natively within the Autodesk Platform, Autodesk Assistant is being introduced to reduce friction, simplify common tasks, and help teams stay focused on meaningful work.

With Autodesk Assistant, onboarding becomes more intuitive. Teams can get started faster as the Assistant guides project setup and supports collaboration through simple, conversational interactions.

We are working toward neural CAD experiences that turn natural language prompts into editable design geometry, helping teams move from ideas to early concepts more quickly. Reducing the friction of starting from a blank canvas helps teams explore early stage concepts faster and jumpstart iteration.

Through Autodesk’s collaboration with Microsoft, Autodesk Assistant is expected to enable new ways for teams to communicate and present their ideas. You’ll be able to render designs, gather project data, and generate Microsoft PowerPoint presentations with simple natural-language prompts. When these capabilities arrive, they are intended to cut down the time spent formatting slides or assembling visuals, letting teams focus on insight and storytelling while Assistant handles the production work.

Text-to-Command through Autodesk Fusion will bring natural-language interaction directly into everyday CAD modeling. Instead of hunting for tools or repeating common operations, you will be able to describe what you want to do, and Assistant will carry out the corresponding Fusion commands.

In manufacturing, Autodesk Assistant is evolving to act as a conversational guide inside Fusion – helping CAM programmers and machinists get more out of the tools they already use. Over time, Autodesk Assistant is expected to deepen its role in Fusion’s manufacturing experience, making it easier to discover capabilities, apply best-practice templates, and keep programming steps aligned with evolving design intent.

Learn more about how Autodesk Assistant is shaping the future of design and make.

Watch the Autodesk AI Keynote.

Scalable automation

We’re also continuing to advance the System Automation Modeler as a core foundation for building and reusing automation in Fusion.

System Automation Modeler enables you to create automation workflows using a visual, node-based approach that’s easier to understand, maintain, and share. Our focus is on enabling workflows that can be packaged, versioned, and reused across teams and projects, reducing reliance on one-off scripts and fragile setups.

Together, these efforts are designed to improve efficiency and clarity while maintaining trust, security, and enterprise governance.

Data Management

Data management in Fusion is entering a new phase, one that reflects how modern product teams actually work. As products grow more complex and teams become more distributed, data is no longer just something to organize or store. It becomes the connective tissue across design, simulation, manufacturing, and collaboration, and increasingly the foundation for intelligent, automated workflows.

When data is fragmented across files, tools, and handoffs, teams lose time, introduce risk, and struggle to scale. Our direction for Fusion Data focuses on strengthening this foundation so teams can collaborate with confidence, reduce rework, and move work forward without constantly managing process overhead.

To support this, our roadmap is centered around three outcomes: connected engineering, connected organizations, and automation with actionable insights.

Connected engineering

Connected engineering starts with a data foundation teams can trust. We will continue investing in reliable, enterprise-ready cloud data management that supports predictable collaboration as projects grow in size and complexity. This foundation directly supports core Design workflows, helping ensure that assemblies, configurations, and drawings remain connected and predictable as teams collaborate, and designs evolve.

We are focused on improving the everyday collaboration moments that happen constantly across teams, such as editing, reviewing, sharing, and coordinating changes. This includes making it easier to share designs at specific points in time or revision states, helping teams collaborate with greater clarity and confidence. We are also continuing to make it easier to bring external CAD data into Fusion, including SolidWorks assemblies, by preserving assembly structures and external component relationships so teams can transition existing work without rebuilding or restructuring assemblies.

As reuse becomes more critical to efficiency, we are making it easier to find, insert, and build on existing parts and sub-assemblies. Improvements to copy workflows will better account for referenced data, helping teams reduce repetitive effort and avoid recreating work that already exists across Fusion hubs.

Understanding how designs are connected is just as important. We are working toward clearer visibility into relationships and dependencies across CAD data, allowing teams to assess impact before making changes, helping reduce unintended downstream effects, and manage increasingly complex product structures with confidence.

Connected organization

As collaboration expands beyond individual teams, data must support the broader organization. Our direction is to strengthen the digital thread that connects disciplines, roles, and stages of the product lifecycle, reducing reliance on disconnected exports, file based handoffs, and manual translation between tools.

We are building task and project coordination capabilities directly into Fusion, connecting work more closely to designs, assemblies, and BOMs. By anchoring planning and execution to the underlying data, teams gain shared context, clearer ownership, and better alignment across engineering, manufacturing, and program stakeholders. This connected data flow reinforces downstream Manufacturing workflows, helping ensure design intent, BOMs, and release states remain aligned as work moves toward production.

Control and governance remain critical as teams scale. We are continuing to improve collaboration controls, sharing workflows, and security capabilities so organizations can apply appropriate guardrails without slowing teams down. Alongside this, we remain focused on trust at a global level, including data residency, compliance, and performance, helping ensure Fusion can support enterprise and regulated environments with confidence.

As work moves downstream, clarity around what is in progress versus what is approved becomes essential. Continued investments in revision controls, lifecycle readiness, and Manage integrations help ensure the digital thread remains intact as work transitions from design into manufacturing and beyond.

Automation and insights

The next evolution of data management goes beyond organization toward systems that actively help teams work smarter. Our direction is to embed automation and intelligence directly into data driven workflows, reducing manual effort and helping teams surface risk earlier. By embedding automation at the data layer, these capabilities complement design and manufacturing automation efforts without breaking traceability across the product lifecycle.

We are investing in practical, workflow embedded AI that keeps teams in control while reducing time spent on repetitive tasks. Early focus areas include AI assisted onboarding and setup, prompt based BOM and property updates, and tools that help prevent part duplication during product development. These improvements are designed to support faster decision making while preserving intent, consistency, and accountability across teams.

We also recognize that workflows increasingly span multiple tools and systems. To support this, we will continue enabling extensibility through MCP tools and APIs, allowing teams to integrate Fusion Data into broader, agent driven, or customized workflows while maintaining a consistent and trusted data foundation.

Design

As assemblies grow and timelines compress, we are shaping design workflows that help teams navigate complexity with greater clarity and control. In 2026, Fusion will focus on strengthening how professional teams design together, reducing manual effort through expanded automation, and making it easier to build on and reuse existing work as designs change and scale.

Assemblies for teams

Assemblies are foundational to professional product development, and we will continue to evolve them to better support how teams design, review, and iterate at scale. Our direction will focus on assemblies that are easier to build, understand, and modify as designs change, with clearer component relationships and more predictable behavior over time. This can reduce rework, support reuse, and help teams move designs forward instead of rebuilding them.

We will improve how assemblies respond to change across contributors and design stages. By strengthening constraints and intent driven design, informed by community feedback, updates will behave more consistently and in line with design intent, even as assemblies grow in size and complexity. These improvements will help teams collaborate more effectively and reduce unintended downstream changes.

As these foundations mature, Fusion assemblies will become a more intuitive environment for multiuser teams and mixed tool workflows, delivering the predictability and control expected from professional engineering software.

Advancing modeling and sketch capabilities

We are continuing to advance core modeling and sketching capabilities to help teams design complex consumer product components with greater precision and fewer workarounds. This includes the introduction of Isoparametric Curves, which make it easier to derive sketch geometry directly from surfaces, reducing the need for repetitive construction geometry when splitting, trimming, or refining faces. By extracting single or distributed curves from faces within the sketch environment, you will gain better control over surface continuity, while supporting higher quality lofted and surface driven geometry.

At the same time, we are refining sketch quality and usability by addressing issues like erroneous short lines, while also improving silhouette projection and color contrast of sketch entities across Fusion environments. By listening closely to customer feedback, we are turning real pain points into meaningful changes teams can feel in their day-to-day work. These efforts are complemented by refinement of construction geometry workflows, with more intuitive forward creation workflow and expanded capabilities including patterning of planes, snap points and perpendicular plane that improve velocity as designs take shape.

Configurations

Configurations are critical for managing product variation, especially in consumer product design where families of related designs must stay organized, connected, and true to intent. As Fusion evolves, we will focus on embedding richer intelligence directly into configurations, allowing variation to be defined and ingrained in the design rather than managed through manual duplication or disconnected models. This direction will move configurations beyond static options toward designs that respond to intent, constraints, and manufacturability considerations from the start. Instead of defining every possible variant upfront, teams will be able to generate the right configuration when it matters, supporting faster exploration and clearer decision making. This approach will also support more structured variation in industrial equipment design, where consistency and control across options are critical for functionality.

Expanded automated drawings

We will continue advancing automated drawing workflows, building on recent updates that modernized the automated drawings experience and made templates and standards more accessible and customizable for professional teams. This foundation allows us to go further in how automation supports real documentation workflows, especially as designs move between contributors and toward manufacturing.

Our direction places a strong emphasis on auto dimensioning, with a shift away from single step automation toward more guided and progressive approaches. These workflows will help teams move toward complete and accurate drawings with greater confidence, while maintaining control over standards, intent, and downstream requirements. As automation expands, it can reduce manual effort, improve consistency across drawing sets, and make it easier for teams to produce clear, reliable documentation at scale.

Performance and Stability

Performance and stability are foundational to the Fusion experience as the platform evolves. Alongside new capabilities, we will maintain a strong focus on responsiveness, reliability, and scalability across core workflows, particularly as designs grow larger, datasets become more complex, and teams collaborate across more stages of the process.

Our direction builds on ongoing, platform wide investments that strengthen how Fusion handles change, computation, and interaction. These efforts have already resulted in meaningful gains in key workflows and lay the groundwork for continued progress. By continuing to optimize foundational systems, we will improve consistency across modeling, assemblies, drawings, and data heavy workflows, reducing friction in everyday tasks and helping ensure predictable behavior as designs are edited, reviewed, and iterated over time.

These efforts are not isolated to individual tools or workflows. Instead, they will continue to reinforce the overall experience, supporting long sessions, large designs, and professional, multiuser teams who rely on Fusion to remain responsive and dependable as work scales.

Electronics

Electronics continues to be a critical part of successful product development, and Fusion will keep evolving to better support end to end PCB design and documentation workflows. Our direction includes extending drawings capabilities for electronics so teams have the tools they need to clearly document PCB fabrication and communicate design intent throughout the development process.

We will also continue addressing long standing gaps in component library data management and core PCB design workflows, with a focus on reducing friction and improving consistency for professional teams. As electronics and mechanical design become more tightly connected, we will invest in better ways to manage change across workspaces, helping teams stay aligned as designs expand and responsibilities shift between disciplines.

As this area develops, performance and stability will remain a constant priority, supporting larger designs, more complex projects, and multiuser teams working across electronics and mechanical domains.

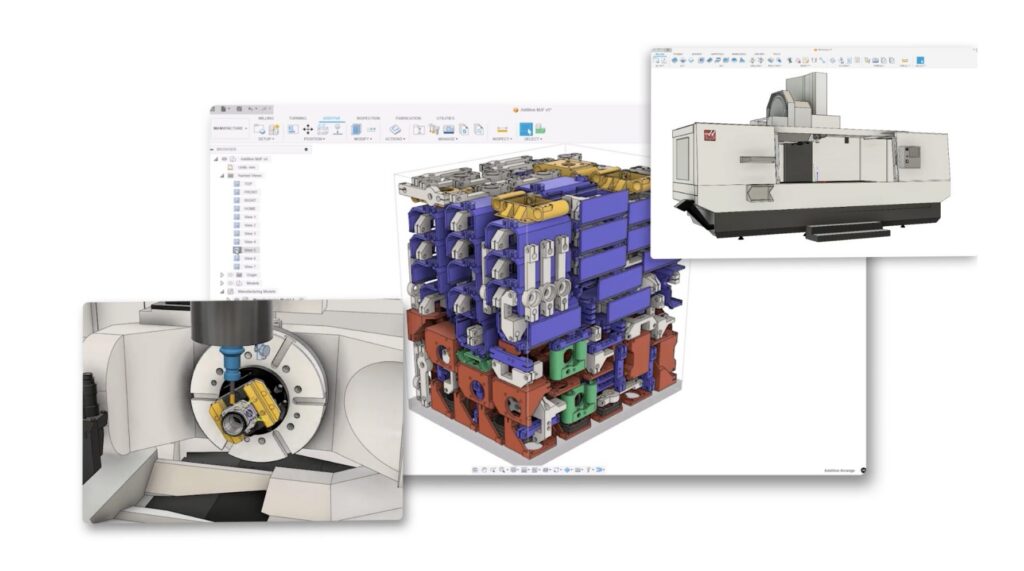

Manufacturing

Manufacturing remains a core pillar of Fusion, with a focus on helping teams move from design to production with greater confidence, efficiency, and consistency. As manufacturing workflows grow more complex and interconnected, our direction is centered on supporting reliable, end-to-end outcomes that scale across teams, machines, and production environments.

Our ongoing investments in Fusion Manufacturing focus on improving first time right results, strengthening confidence in simulation and automation, and making it easier to establish and reuse best practices. These efforts help professional teams reduce iteration, manage change more effectively, and maintain alignment between design intent and manufacturing execution as work moves toward production.

Mold, tool, and die machining

Mold, tool, and die work pushes CAM systems harder than almost any other workflow. Large models, complex surfaces, and tight tolerances demand predictable toolpaths and responsive performance.

Enhancements in this area focus on improving the quality and consistency of milling and multi axis toolpaths, with attention to smoother motion, better boundary handling, and more stable behavior as designs evolve. Performance improvements also play a role, helping large and detailed programs remain responsive during programming and iteration. Together, these changes help reduce trial and error and give teams greater confidence when tackling demanding machining challenges.

Production machining and turning

Production environments increasingly rely on advanced lathes and mill turn machines, where accuracy and validation are critical before a program ever reaches the shop floor.

Improvements here center on stronger representation of 3D turning tools and tool blocks, alongside more capable turn mill simulation. By validating behavior earlier and more clearly, teams can shorten prove out time and maintain consistency across modern CNC setups.

Design to manufacturing workflows

Manufacturing efficiency is shaped long before toolpaths are created. How clearly design intent carries into manufacturing has a direct impact on rework, automation, and downstream confidence.

Continued investment in PMI authoring allows tolerances, threads, and surface requirements to be defined directly on the model and consumed more reliably in manufacturing workflows. In parallel, selection tools are becoming more resilient and consistent across workspaces, helping manufacturing workflows stay stable as designs change.

Sheet metal: design to fabrication

Sheet metal remains an important growth area for Fusion, and our investments are focused on enabling confident, production ready workflows from design through fabrication.

We are enhancing flat pattern accuracy through improved unfold logic, along with stronger fabrication outputs such as DWG, DXF, and STEP. In parallel, we are improving how sheet metal rules can be shared and reused across teams, supporting greater standardization and consistency across organizations.

Alongside these foundations, we will continue investing in productivity, usability, and API extensibility so sheet metal workflows are faster, more intuitive, and easier to integrate into broader manufacturing processes.

Automation in manufacturing

Automation continues to play an increasingly important role in manufacturing when it is predictable, repeatable, and scalable. Across Fusion Manufacturing, we are strengthening the foundations that allow automation to be applied more consistently in production workflows.

This includes expanding automation for high frequency tasks such as hole making, helping reduce repetitive programming work while maintaining visibility and control. We are also investing in cloud-based execution, reuse, and governance capabilities so automation can scale across teams, machines, and locations without relying on fragile or one off setups.

Help us shape the future of Fusion

Do you want early access to some of the capabilities discussed here and the opportunity to help shape what comes next? Consider joining our Insider Program, where you can provide direct feedback and collaborate with our teams as these experiences continue to evolve.

DISCLAIMER: Roadmaps are plans, not promises. We’re as excited as you to see new functionality make it into the products, but the development, releases, and timing of any features or functionality remain at our sole discretion. These statements are not intended to be a promise or guarantee of future delivery of products, services, or features but merely reflect our current plans, which may change. Purchasing decisions should not be made based on reliance on these statements.