With the numerous innovative electric vehicles on the road today, it may seem surprising to consider that a classic, gas-powered car could be more sustainable than its modern counterparts. Picture this: under the hood, the engine is removed and replaced with a smooth, reliable battery. No new materials or manufacturing are required. It’s a bold move for the circular economy and the ultimate reuse of existing vehicles. Less noise, less pollution, and the undeniably cool, retro style remains.

This isn’t just hypothetical. Based in the UK, Fellten is making the transformation and retrofits of old MINI Coopers, Porsches, and Land Rovers into clean electric vehicles a reality.

“The goal is to basically give all of these classic cars a new life by creating a solution that you can bolt in without changing the bones,” says Lucy Dicken, design engineer, Fellten.

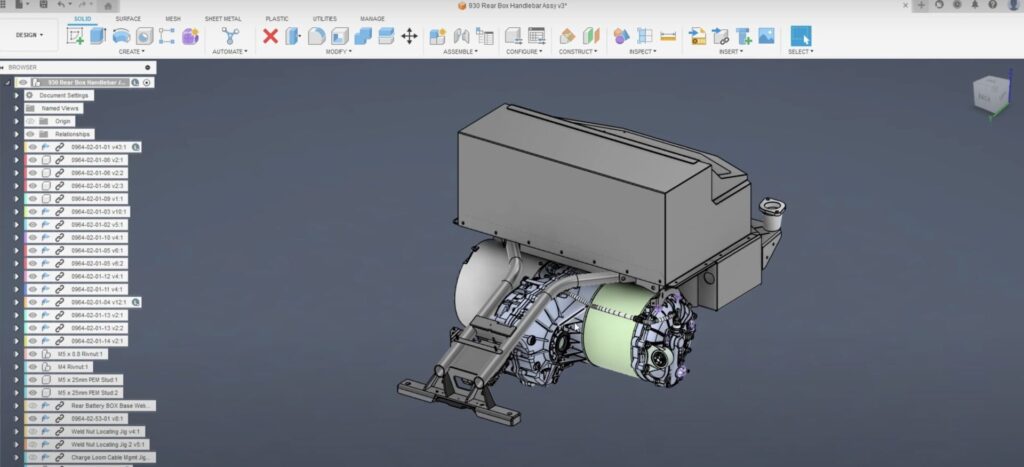

“With our projects, we’re basically taking an item that was not designed to be electric, which involves a humongous amount of design and development,” adds Chris Hazell, co-founder and CEO, Fellten. “We’re fundamentally taking a battery that’s normally underneath a car and making it engine-shaped to put under the hood. At the same time, we’re doing this without making any modifications to the original chassis or vehicle at all.”

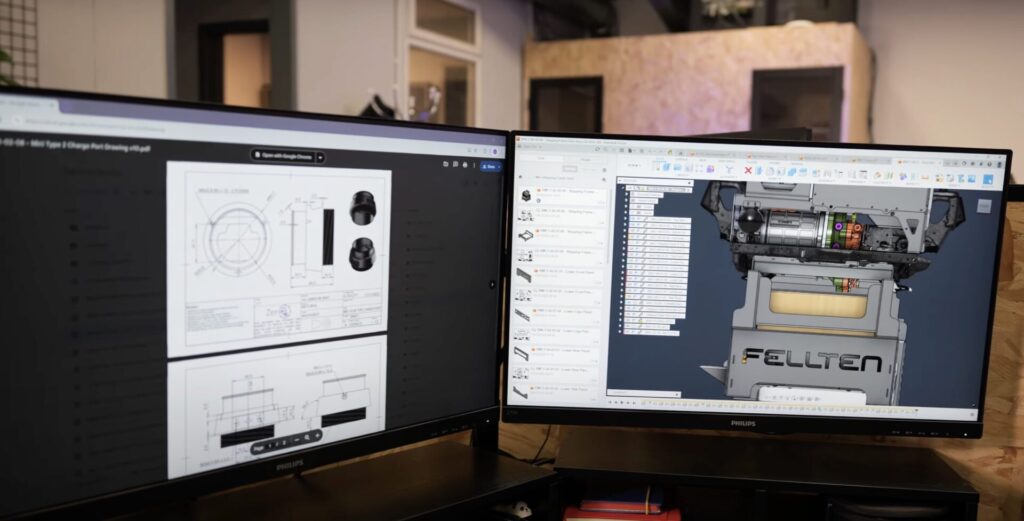

And, from the very beginning, they’ve used Autodesk Fusion to bring their electric battery systems and products to life.

Inside look at the design process

Of course, it isn’t as simple as taking a battery and swapping out the combustible engine in a classic car. Each vehicle is different and requires its own specific design to ensure the battery and all the electronics will fit—whether it’s a MINI Cooper, Porsche, or Land Rover.

“We get a lot of scan data that we import into Fusion just to make sure our designs will fit before we go on to prototype and then manufacture to install in real life,” Dicken says. “We also keep the weight as close to the original car as possible, so it handles and performs the same way.”

“The sheet metal features on Fusion make it so quick to just make a prototype model. With manufacturing, we can easily change our bend radii and sheet metal thicknesses to match whatever is on the machine.”

—Lucy Dicken, Design Engineer, Fellten

Their design workflow typically starts with a brainstorming session to collect the team’s input and agreement on an idea to move forward. It then goes into Fusion, where a rough CAD model is started to include critical dimensions, electronics design, and key features where the entire team can collaborate seamlessly in the cloud. After a design review, a new, clean CAD model is completed with all the finishing touches. Then it’s on to physical prototyping followed by the final design for manufacturing process. The entire process typically clocks in around three months.

“Batteries are extremely heavy, and lifting one in and out of a vehicle to do measurements and the like is just not an option,” Hazell says. “With Fusion, we can basically take every single component, visualize it in a 3D space, and test multiple iterations quickly.

“If you did this physically, it would take months and months, and you’d spend a huge amount of money on materials and trying things out,” he adds. “In the CAD world with Fusion, you can very quickly design, develop, and test. We can also do stress analysis and even look at things like flow rates with our liquid cooling plates to make sure we’re getting the right cooling systems for the batteries.”

“In previous roles at companies using other software, I’d have to wait until the mechanical team would actually finish their design before I could start on my own electrical design. With Fusion, I can start before they’re done, and it saves days, if not weeks, of time.”

—Louis Malster, Head of Electronics Development, Fellten

Cars and boats are only the beginning

Fellten isn’t limiting itself to only car retrofits and has continued to evolve with the design of electric battery packs for a variety of applications, including brand new boats. They have also strategically identified the need for better charging infrastructure for fleet customers to adopt electric vans.

With that opportunity in mind, Fellten is now expanding with the new Charge Qube, an innovative mobile solution that brings scalable energy storage and EV charging anywhere. It repurposes EV batteries, enabling them to live on another 15-20 years to charge new electric fleets. Charge Qube can either be used with 3-phase grid supply or renewable energies such as solar or wind, and it’s highly transportable to remote and even semi-permanent locations.

“The main goal for Fellten is to provide a more sustainable future, looking at end-of-life battery packs, especially with the Charge Qube,” Dicken says. “We want to provide a circular economy for end-of-life battery packs, giving them another use and providing a charging solution that can be deployed basically anywhere in the world.”

“What excites me most about Fellten is the fact that we’re actually going to start making a massive environmental difference,” Hazell adds. “Yes, we’ve been saving beautiful classics and retraining people into a new industry. But with our energy storage products, we’re actually going to be able to get high-emission van fleets transitioning to electric faster. We’re going to help that transition to a net-zero world as fast as possible, and we can use Fusion to design these products to help make it happen.”