Partha Pratim Das Mahapatra’s mother was only 37 years old when she developed severe heart complications. Only after surgery did doctors identify the underlying cause of long-term, untreated anemia.

Anemia affects roughly one in four people globally. Yet despite being easy to treat, it often goes undetected. Traditional testing requires blood draws which often discourages screening, particularly among children, rural populations, and people without easy access to clinical facilities.

Mahaptra built a successful career in software engineering and IoT systems at companies including Capgemini and Grant Thornton. But, in the back of his mind, he always had the challenge of widespread anemia testing on his mind. Then he decided it was time to find a solution. He founded EzeRx and set out to remove that barrier entirely.

“My mother’s health issues made me want to create an impact,” he says. “In my career, you start with a difficult problem statement, and you transform it into a solution. So I thought: let’s work on this problem statement.”

Creating a needle-free solution for testing

Mahapatra decided to pursue an ideal solution where anemia testing wouldn’t require any blood at all. For three and a half years, Mahapatra and his wife and co-founder Chaitali Roy tested different approaches and ways to transmit, capture, and interpret light to diagnose anemia instead of traditional blood draws. They tried illuminating the eye, then the nail bed. Eventually, they honed in on the fingertip.

The result was EzeCheck, a compact, non-invasive handheld device that estimates hemoglobin levels when a user places a finger on it. EzeCheck leverages spectrophotometry, in which white light is reflected from the fingertip, alongside optical signal analysis and AI and machine learning algorithms to estimate hemoglobin levels.

With laboratory-grade accuracy, the test is painless and delivers results in under a minute. Not only that, it is also sustainable. Removing disposable testing supplies and reducing dependence on centralized laboratories, EzeCheck has helped avoid more than 15 tons of biomedical waste, save 46+ kilotons of carbon emissions, and conserve over 6,000 liters of blood that would otherwise have been drawn for testing.

“By eliminating waste and complexity from medical devices, we don’t just optimize performance —we protect patients, communities, and the planet,” Mahapatra says.

Redesigning EzeCheck with Autodesk Fusion

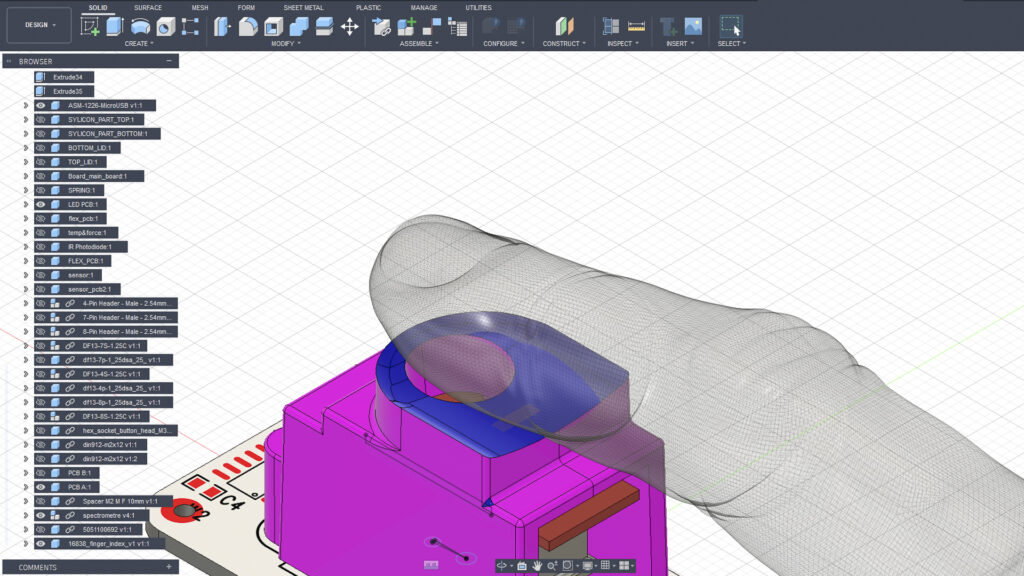

As EzeCheck gained wider adoption, Mahapatra and his team set out to redesign the device for higher-volume manufacturing and increased durability with Autodesk Fusion.

Working alongside hardware engineer Diptadip Barai, the team built the entire enclosure directly in Fusion using a full 3D workflow, modeling every element from the finger bed and sensor mount to the hinge mechanism. This unified approach in the cloud enabled faster iteration cycles and version control as designs evolved.

Before investing in molds that require significant financial commitment and environmental considerations, the team used Fusion’s simulation capabilities to stress-test every plastic component. They evaluated wall thicknesses, rib structures, and load points, analyzing durability and performance to confirm the device would withstand real-world use.

By validating designs virtually, the team reduced the number of physical prototype cycles, saving materials, time, and cost. The process also helped optimize the enclosure for lighter weight and minimal material use, reinforcing EzeRx’s sustainability objectives.

“Fusion is a game changer for product design,” Mahapatra says.

Read more about EzeRx, EzeCheck, and what’s in store for the future on Design & Make with Autodesk: Designing for health, designing for impact: How EzeRx is reimagining health care solutions for India and beyond