AI integration in product design presents both technical hurdles and potential. Autodesk Fusion addresses these obstacles through a combination of AI-driven features like generative design and a unified, accessible platform that supports consistent data.

Manufacturing and product design workflows have always aimed to improve efficiency and quality. While the means to achieving this end have varied throughout history, modern designers and manufacturers have turned to AI as the solution. Although implementing AI across workflows offers a powerful tool, deployment brings obstacles alongside its benefits. This article explores both sides in depth and details how Autodesk Fusion directly supports organizations seeking to bring AI into their product lifecycle.

Technology in manufacturing AI

Integrating AI into product design and engineering workflows presents a complex challenge. While AI promises increased efficiency, predictive accuracy, and design improvements, the technological pathway to successful implementation often involves considerable friction.

One main issue stems from data infrastructure. While AI systems depend on large volumes of clean, well-structured data to function accurately, many organizations maintain fragmented or incomplete datasets across legacy systems. Using such data hinders model training and decision-making consistency. In the absence of reliable data pipelines, AI outputs are rendered unreliable, and their usage becomes limited.

Algorithmic transparency presents another challenge. Despite the fact that engineers and designers need confidence in their AI’s suggestions or predictions, many machine learning models function as black boxes with limited insight into their internal logic. This opacity can make it difficult to validate outcomes or make traceable decisions.

Skills gaps further complicate adoption. Given that AI tools are multidisciplinary, developing them necessitates expertise in a plethora of fields such as data science and systems integration. However, in most cases, design and engineering teams lack personnel with this hybrid knowledge base. Even when organizations secure such talent, introducing AI development into existing engineering workflows presents cultural challenges. Resistance to automation, concerns about job displacement, and hesitancy around unfamiliar tools deepen adoption friction.

Despite these roadblocks, the benefits of successful AI implementation are substantial. Organizations that overcome the initial challenges of implementation gain access to more adaptive design cycles, reduced prototyping costs, and improved product performance. Predictive maintenance, generative design, and intelligent quality control systems all offer powerful ways for AI to positively reshape practices.

How Autodesk Fusion helps

Autodesk Fusion offers a practical response to the challenges of AI implementation in product design. Fusion reduces the barriers associated with data integration by embedding advanced automation within a cohesive and user-friendly platform. The software offers a holistic data structure where geometry, materials, simulation results, and manufacturing constraints all coexist within a single digital model. This ability guarantees that AI-driven features draw from consistent and reliable information.

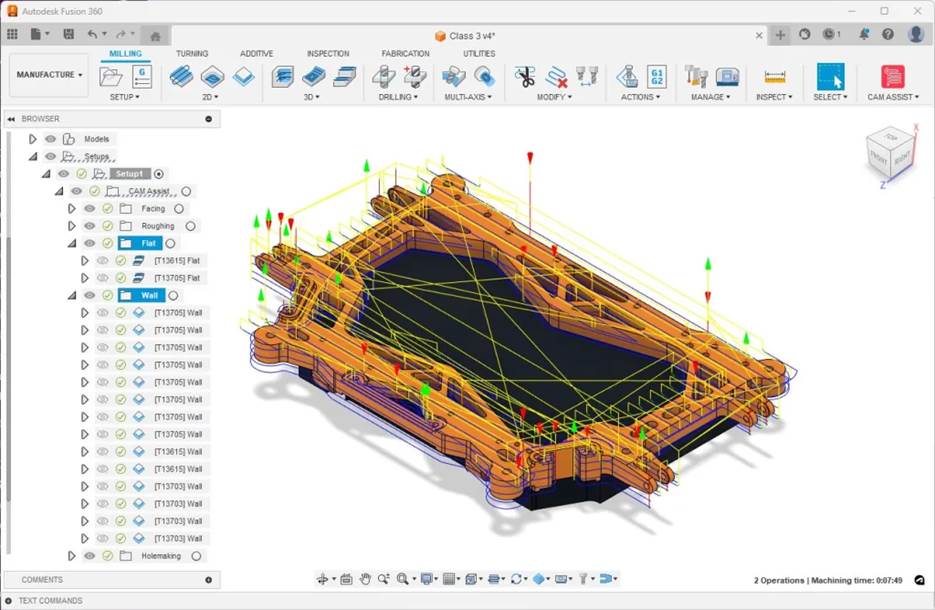

The platform’s generative design capabilities provide an effective introduction to AI-guided engineering without requiring deep algorithmic expertise. Users define objectives, constraints, and performance criteria, and the system returns manufacturable geometry options based on real-world loading conditions. Such features eliminate the need for manual programming or interpretation of AI logic. The process stays transparent through integrated simulation tools that allow users to validate results and iterate confidently.

Fusion also addresses skill and workflow alignment by facilitating access to machine learning features through intuitive interfaces and task-specific modules. Instead of fragmenting work across multiple platforms or data sources, Fusion keeps analysis, design, and automation tools within reach of the same engineering team. By centralizing the workflow, Fusion encourages collaboration between teams without introducing steep learning curves or needing integration with external systems.

For organizations navigating early-stage AI adoption, Fusion provides a stable platform to prototype intelligent workflows. Whether it’s using AI to reduce part weight in aerospace components or to optimize heat dissipation in electronics housings, the software embeds these capabilities within an environment familiar to design professionals. As teams gain confidence and identify where AI adds the most value, they can scale up complexity without needing to overhaul their processes or hire an entirely new technical staff.

From challenges to opportunities

AI adoption offers clear advantages for engineering and product designers, but the path to implementation is challenging. Tools like Fusion make this journey more manageable by embedding AI capabilities within a coherent, user-oriented platform. As companies strive to move from AI concept to applied value, Fusion can help overcome challenges and realize tangible benefits.