Category: Product Design & Engineering

-

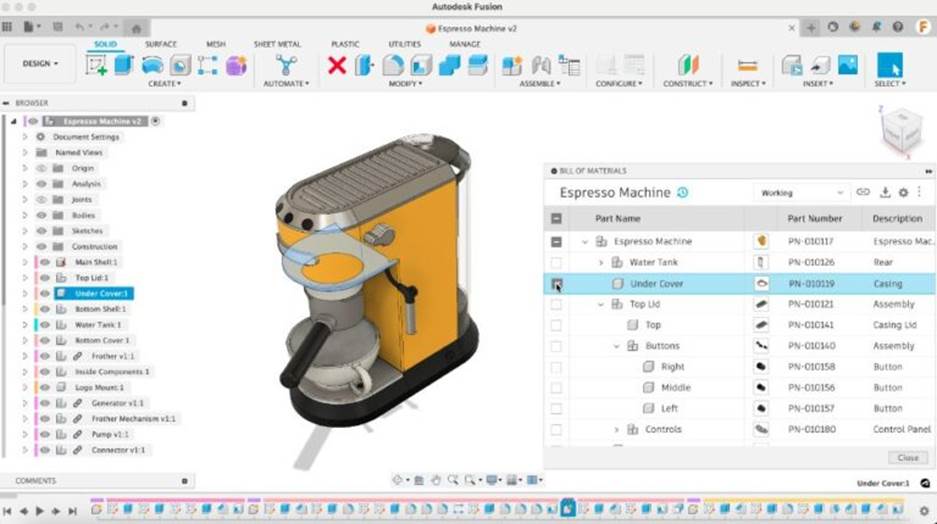

Metrics That Prove Your Connected Product Development Investment is Working

Explore how connected product development improves key engineering metrics of time-to-market, first-pass yield, and cost of poor quality. Learn how integrating ECAD, MCAD, and PLM reduces latency and errors and how Autodesk Fusion can help. Product development teams constantly face pressure to deliver complex designs faster and with fewer errors. One means of alleviating these…

Product Design & Engineering

-

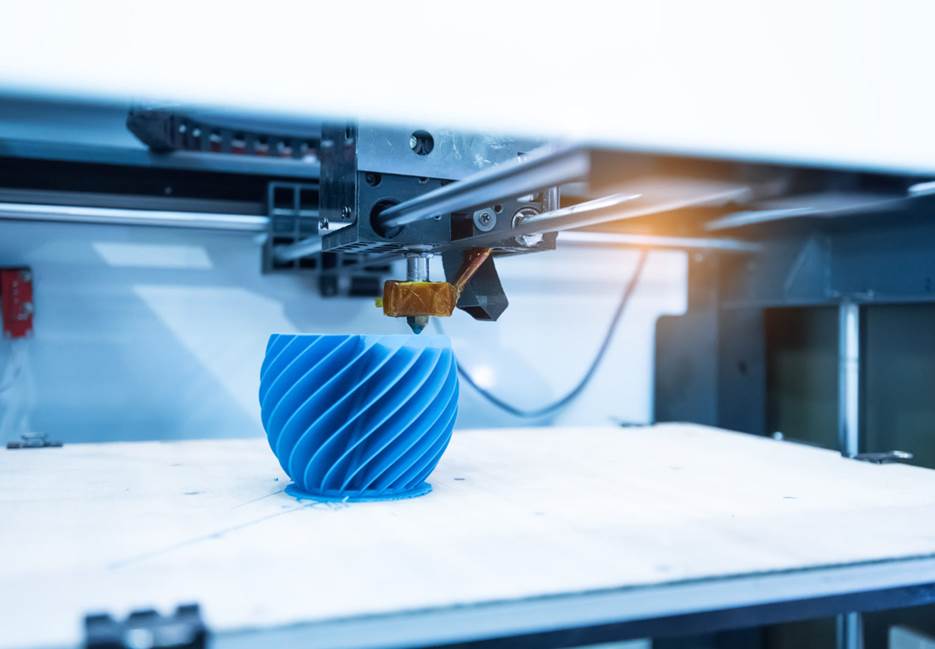

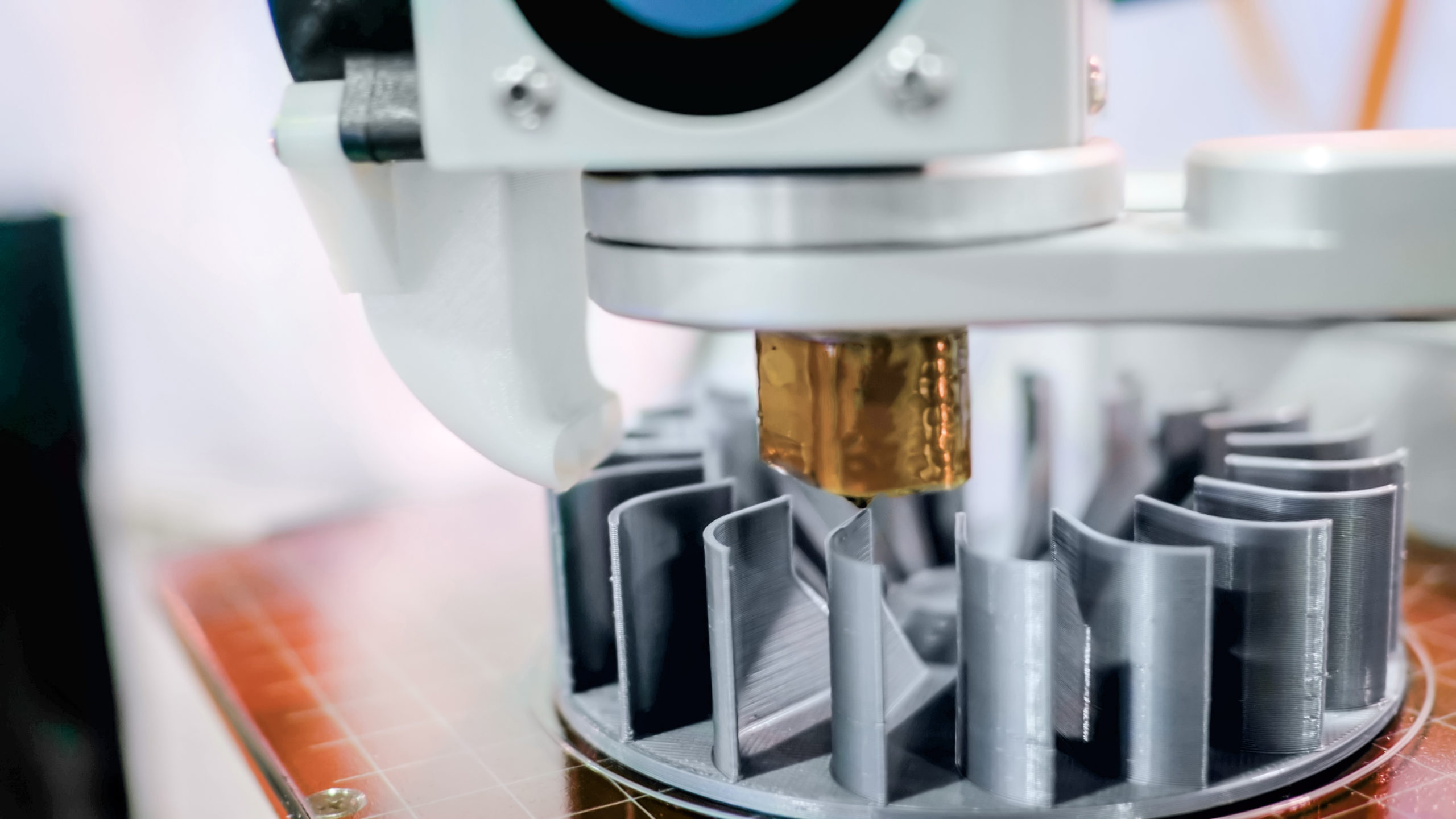

Top 5 Applications of Additive Manufacturing for Product Design

Additive manufacturing delivers value through prototyping, functional testing, customization, lightweighting, and digital inventory. These applications need fast iteration and strong links between design and production. Fusion supports this need by integrating additive preparation with CAD and engineering workflows so that teams improve consistency, speed, and manufacturability. Additive manufacturing has moved well beyond its early application…

Product Design & Engineering

-

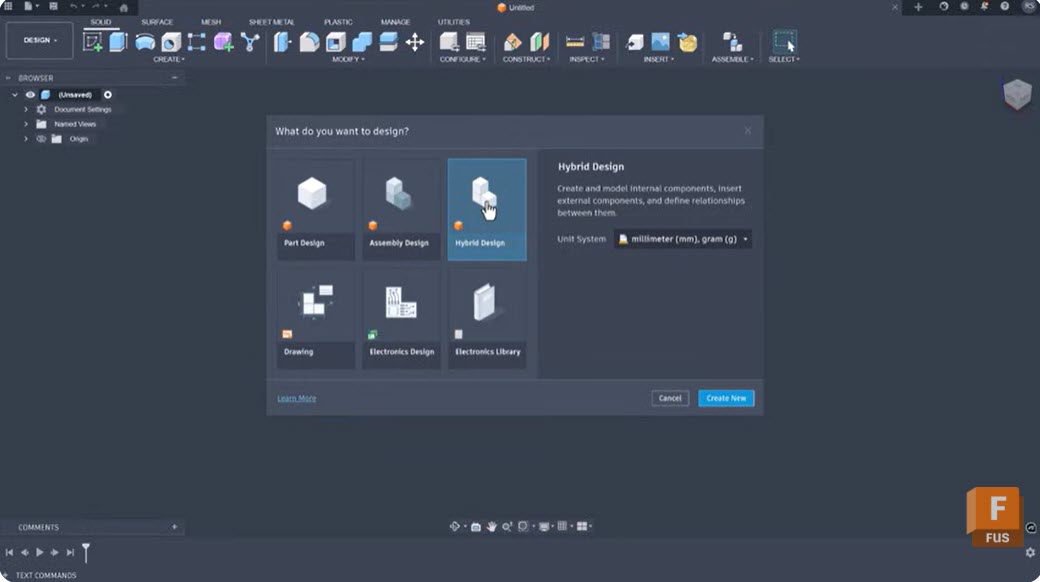

Breaking Free from Rigid Modeling Workflows with Intent-Driven Design in Fusion

Intent‑driven design in Fusion removes workflow friction by helping teams start with the right modeling approach and adapt seamlessly as projects evolve. Design projects often stall before they start – not because of complexity, but because teams are forced into workflows that don’t match how they actually build. When tools lock designers into rigid modeling…

Product Design & Engineering

-

Responding to Disruption: How Educators and Employers Are Reacting to Modern Engineering Challenges

Explore how educators and employers are collaborating to close the engineering skills gap through curriculum innovation, hands-on learning, and industry-integrated workforce development.

Thought Leadership

-

What Can Be 3D Printed? A Complete Guide to Materials Used in 3D Printing [Update 2025]

Using the right material for your 3D printed project can make or break the final result. Fortunately, there are many options to choose from, whether it be plastic, metal, or even polymer.

Tutorials

-

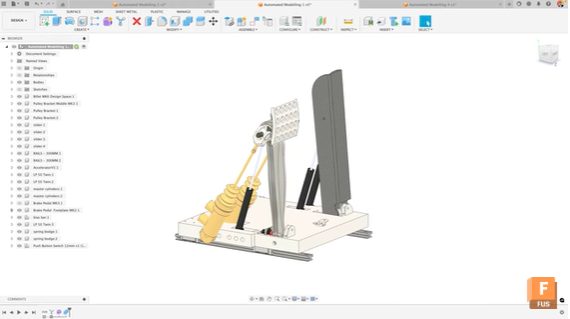

5 Innovative Ways to Use Automated Modeling in Autodesk Fusion

Oliver Briggs, Fusion expert at EduCAD, highlights 5 unique ways to use automated modeling in Fusion to collaborate faster, streamline prototyping, create custom tooling, accelerate design, and optimize workflows. Automated modeling in Fusion is a breakthrough for design and engineering workflows, streamlining tasks that once required hours of manual modeling. While most users know the…

Tutorials

-

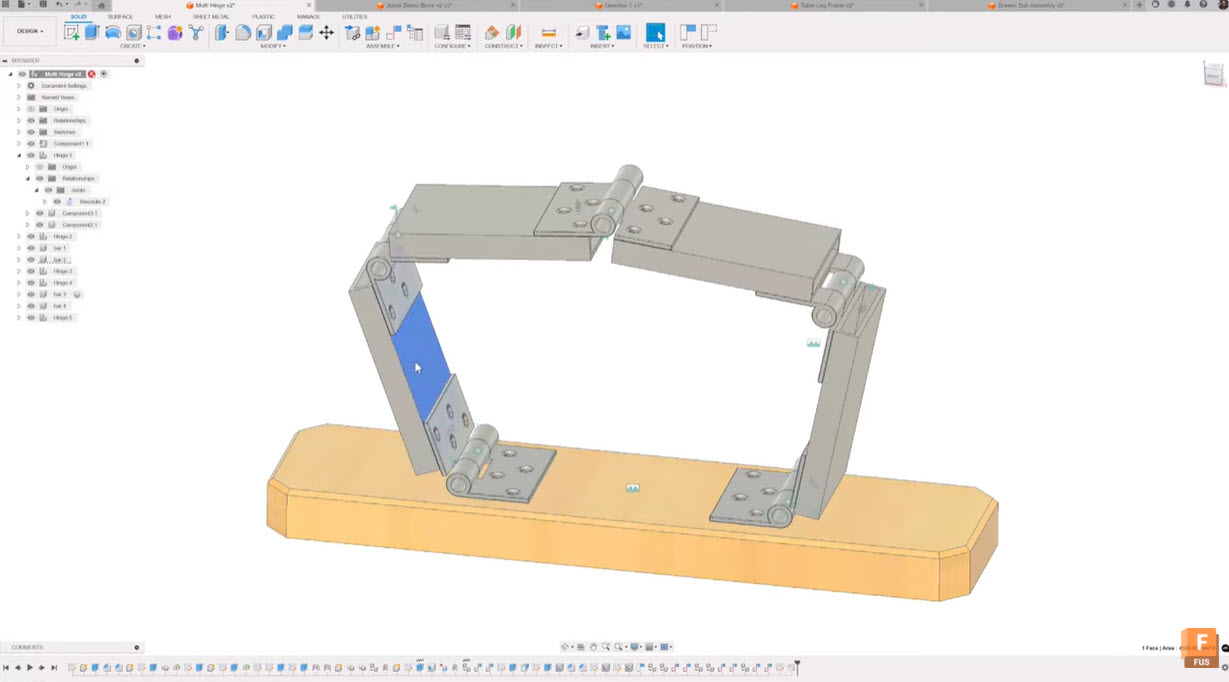

Using Motion Links for Hinged Joints in Fusion

Richard Stubley, Fusion Senior Product Manager shows you how to easily coordinate multiple hinged joints using motion links in Fusion. Learn best practices for joint placement and assembly modeling for smooth, realistic motion. If you’ve ever struggled to coordinate multiple hinged joints in a complex assembly—like a folding A-frame cart with several moving parts, you’re…

Tutorials

-

How AI in Fusion Drives Speed, Efficiency, and ROI for Consumer Product Teams

Explore how AI in Autodesk Fusion helps consumer product companies accelerate development, cut costs, and improve manufacturability. Speed, adaptability, and precision are non-negotiables in today’s consumer product landscape. Buyers are more value-driven, and less brand-loyal than ever. Product portfolios are expanding, customization is expected, and sustainability is non-negotiable. For organizations that must deliver innovation under…

Thought Leadership

-

5 Skills That Will Shape Tomorrow’s Engineering Workforce

Engineers of the future be expected to navigate rapidly evolving tools, tackle complex global challenges, and more.

Thought Leadership

-

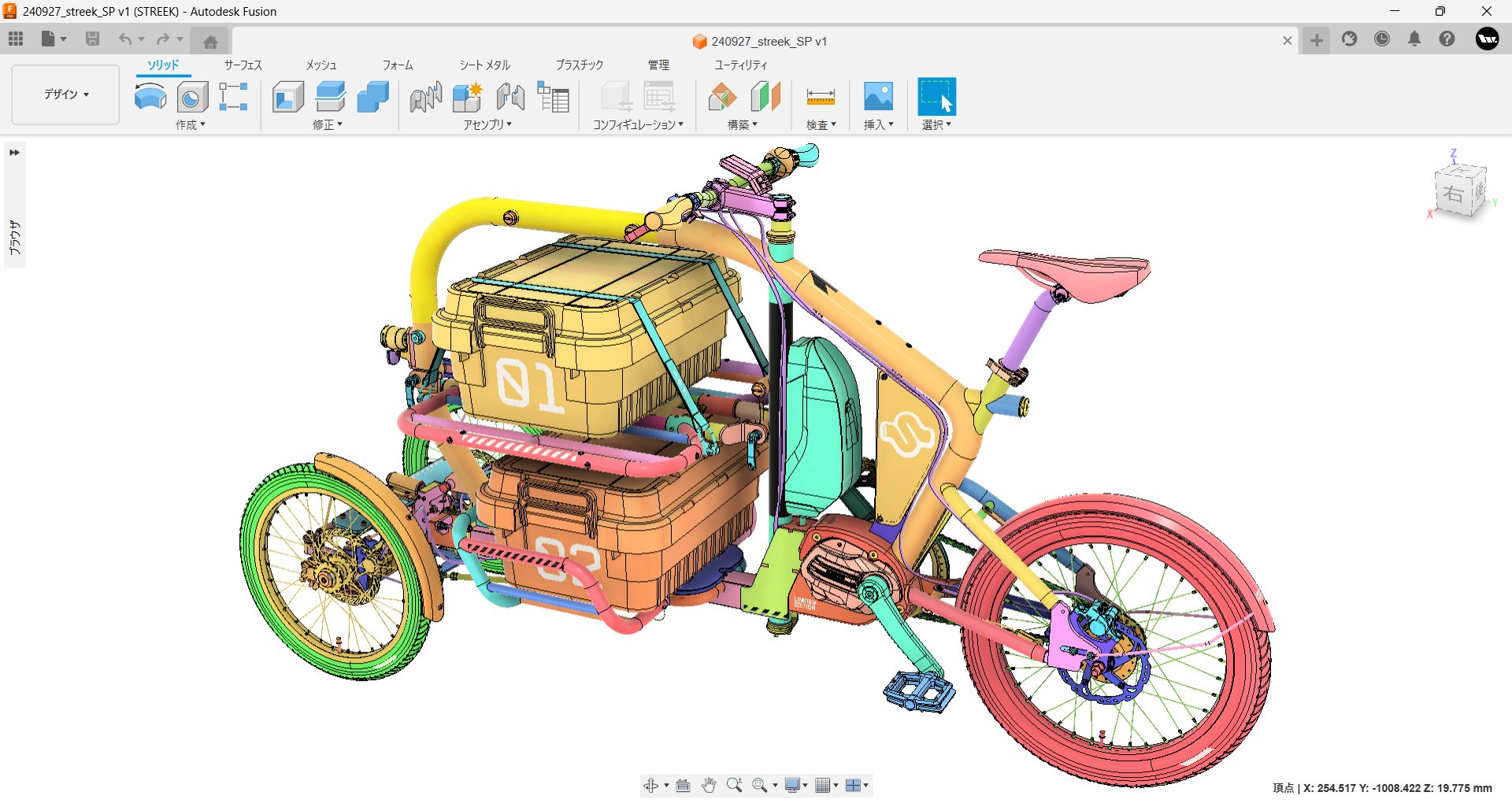

STREEK: A Cargo Trike Fit For Tokyo Streets

STREEK is an electric cargo tricycle from Japan, supported by Autodesk Fusion to bring it from concept to production.

Case Studies