Category: Advanced Manufacturing

-

The Definitive Guide to Designing for Additive Manufacturing

An Engineer’s guide to understanding and implementing additive manufacturing in the production process… Introduction Image Source: Marines Additive manufacturing (AM) is a term used to described the set of manufacturing processes that progressively add layers of material to manufacture your products, and it could change the way you go about engineering your products. Instead of…

Advanced Manufacturing

-

Top 5 Fusion Manufacturing Highlights from 2024

The Fusion manufacturing workspace experienced remarkable advancements in 2024, with new features and enhancements across milling, turning, nesting, and additive

Manufacturing

-

Machine Learning in Design & Manufacturing

Discover how machine learning is transforming design and manufacturing and how Autodesk Fusion leverages AI to optimize workflows and product development.

Advanced Manufacturing

-

The Fourth Industrial Revolution & Fusion

Discover how Autodesk Fusion powers Industry 4.0 with AI, cloud collaboration, and data-driven manufacturing.

Thought Leadership

-

Autodesk Fusion to Design and Manufacture a 5-axis FFF Printer

Generative Machine develops an open-source 5-axis FDM 3D printer, designed using Autodesk Fusion’s generative design and AI-driven tools.

Advanced Manufacturing

-

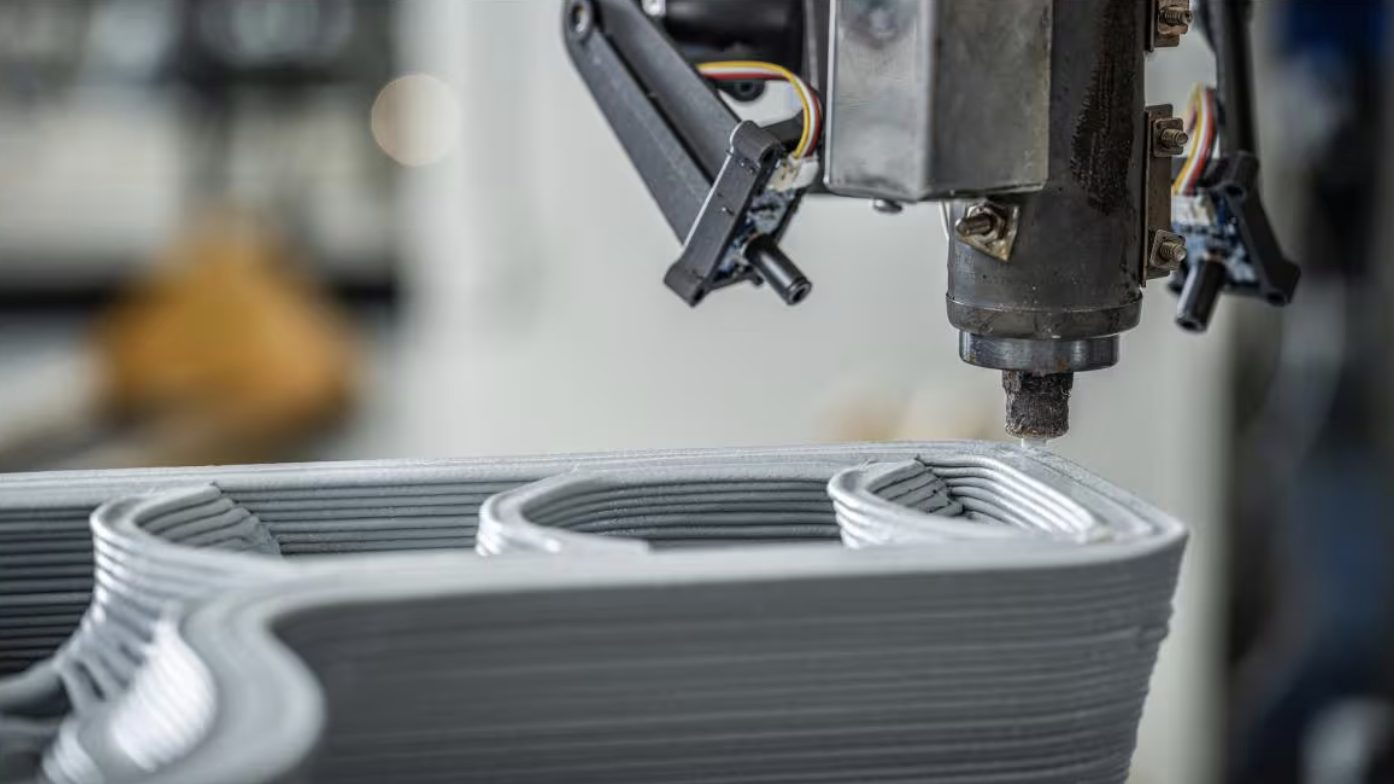

What is FDM?

Discover Fused Deposition Modeling (FDM), its processes, benefits, and applications across industries. Learn how Autodesk Fusion optimizes FDM workflows for design and manufacturing excellence.

Advanced Manufacturing

-

Elevate Your Manufacturing Game with Kennametal Import Tools

We’re excited to introduce Kennametal Import Tools—a game-changing application designed to enhance your capabilities and fuel innovation.

Advanced Manufacturing

-

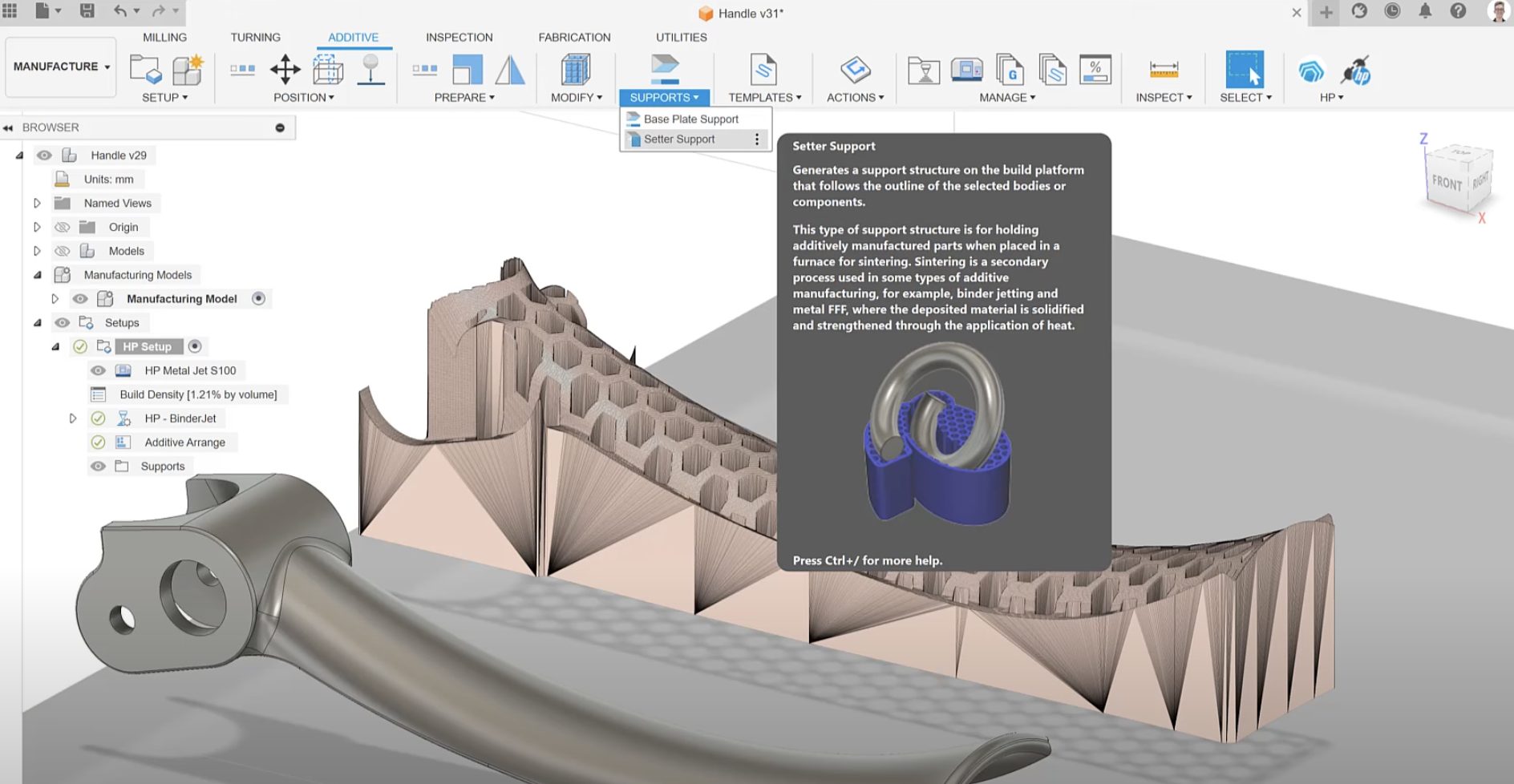

Using Setter Supports for Sintering in Additive Manufacturing

Learn how to create and optimize support structures in Autodesk Fusion to enhance the sintering process. This guide covers everything from setup to generating and managing supports, ensuring your parts maintain precision and quality during additive manufacturing. Supporting part during sintering is an important process in additive manufacturing as it ensures the quality and precision…

Advanced Manufacturing

-

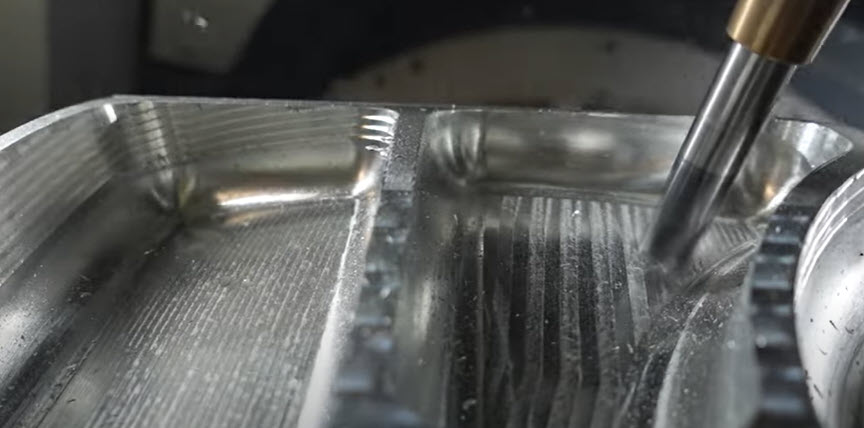

Reduce Cycle Time with Circle Segment Cutters in Autodesk Fusion

Circle segment cutters in Fusion reduce cycle times and maintain high-quality finishes, enhancing efficiency and profitability in machining complex geometries. The way a component’s geometry is machined significantly impacts both cycle duration and surface finish quality. These factors can either increase or decrease the total cycle time. This directly affects the cost of the component…

Manufacturing

-

5 Ways Autodesk Fusion Can Leverage Autodesk AI Today

Autodesk AI helps you move beyond non-value-added tasks so you can focus on what truly matters to your business: driving innovation.

Thought Leadership

-

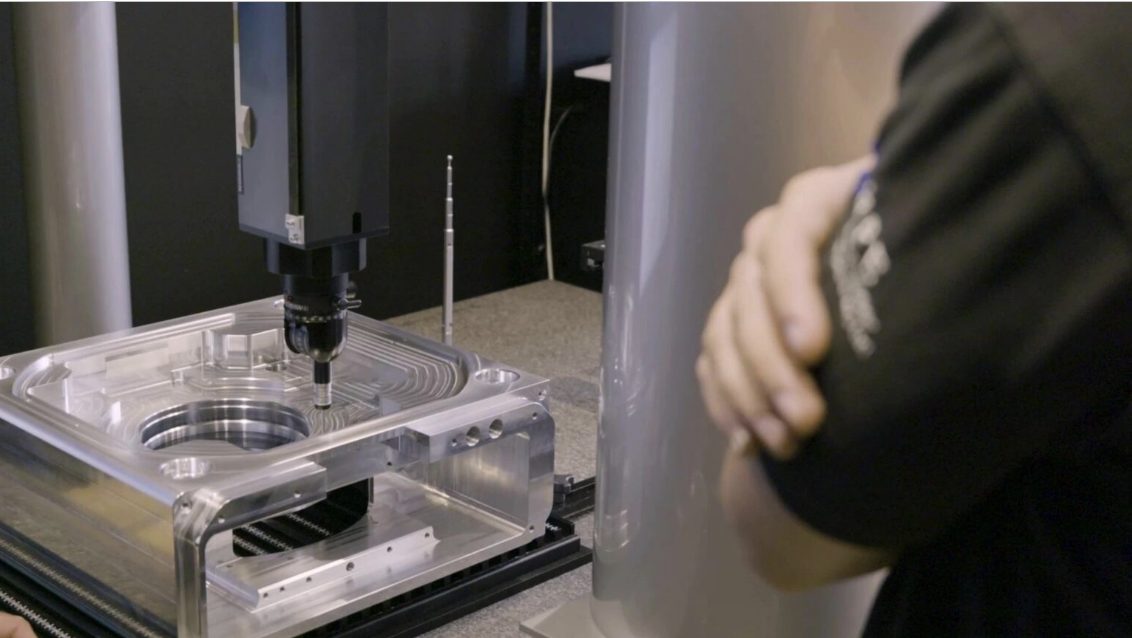

CNC Machining 101: A Comprehensive Guide

Explore CNC machining basics, machine types, and how Autodesk Fusion enhances precision and productivity in modern manufacturing.

Manufacturing

-

Factors Shoe Design and Manufacturing Companies Must Consider When Choosing a Software Solution

Discover the critical factors shoe design and manufacturing companies must consider when selecting a software solution, and learn why Autodesk Fusion is the ideal choice for seamless integration, advanced 3D modeling, customization, and scalability.

Product Design & Engineering

-

How 3D Printing is Transforming Education

In education, 3D printing, supported by tools like Autodesk Fusion, enhances learning by making complex concepts tangible, fostering creativity, and preparing students for future careers.

Manufacturing

-

Additive Manufacturing: The Next Generation in Laser Powder Bed Fusion

Autodesk and SCANLAB have created a real-time closed-loop control system for laser powder bed fusion processes, enhancing precision and efficiency in additive manufacturing.

Manufacturing