Cut errors, speed launches, and improve collaboration with Autodesk Fusion’s integrated PDM—one platform for design, manufacturing, and data control.

Elevate your design and manufacturing processes with Autodesk Fusion

Data is the backbone of every product decision. Yet, many organizations still rely on manual processes and fragmented systems to manage product data – costing them time, money, and market share. Studies show businesses lose up to 25% of productivity due to inefficient data management, with teams spending hours searching for files, resolving version conflicts, and correcting errors caused by outdated information.

The solution? Product Data Management (PDM)—a systematic approach to organizing, storing, and controlling all product-related data throughout the entire lifecycle. From initial design concepts to manufacturing and service, PDM ensures teams work from a single source of truth, improving accuracy, collaboration, and speed.

Why PDM matters more than ever

Disconnected workflows create friction. Engineering teams struggle with version control, manufacturing teams receive outdated specifications, and global collaboration becomes a logistical nightmare. These inefficiencies lead to costly errors, delayed launches, and missed opportunities.

Modern PDM systems eliminate these pain points by:

- Centralizing data for easy access and control.

- Automating version management to prevent errors.

- Streamlining workflows for faster approvals and change management.

- Enabling real-time collaboration across global teams.

The measurable impact of PDM

Organizations that implement PDM report dramatic improvements within months. Industry benchmarks reveal:

- 30–50% fewer design errors thanks to centralized data and automated version control.

- 25% faster product launches through concurrent engineering and automated workflows.

- 40–60% reduction in data retrieval time, freeing teams to focus on innovation.

- 20–30% boost in engineering productivity by eliminating manual coordination and rework.

These gains translate into real ROI—most companies achieve payback within 3–6 months of deployment.

Benefits that drive business outcomes

PDM isn’t just about storing files—it’s about transforming operations. Here’s how:

1. Enhanced collaboration

Real-time data sharing eliminates version conflicts and miscommunication between engineering, manufacturing, and sales teams. Global teams can collaborate 24/7 without waiting for file transfers or email confirmations, accelerating decision-making and reducing delays.

2. Accelerated time-to-market

Concurrent engineering workflows allow multiple teams to work simultaneously on different components, cutting development cycles by 20–35%. Automated data synchronization ensures everyone works from the latest information, eliminating bottlenecks.

3. Improved data accuracy

A single source of truth prevents duplicate files and conflicting specifications. Automated version control ensures only approved data reaches manufacturing, reducing costly errors and rework.

4. Stronger compliance and governance

Audit trails, role-based access, and automated workflows simplify regulatory compliance and protect intellectual property while enabling seamless collaboration.

5. Cost reduction

By reducing rework, eliminating duplicate purchasing, and streamlining approvals, companies report 25–40% decreases in design-related corrections and significant savings in IT infrastructure costs through cloud-based solutions.

“Fusion helped us a lot because we were working with three types of companies, and therefore you need one hub where all the data and all the R&D work is being stored and managed. Fusion helped us save on costs because if you take an average design process of such an implementation, it takes up to 24 months. We did it in six months.”

–Thomas Adam Saier, Head of Design, O’NEAL Europe

Fusion for PDM: One platform, complete control

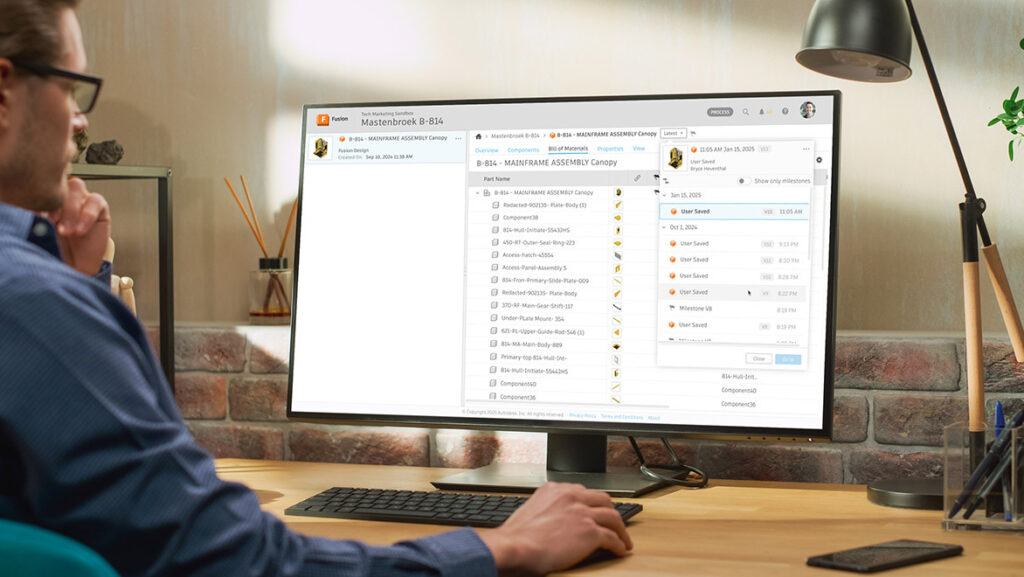

While traditional PDM systems often require complex integrations and additional software, Autodesk Fusion delivers built-in PDM capabilities as part of its cloud-based platform. This means you get:

- Centralized, secure data management without extra tools.

- Real-time collaboration across global teams with controlled access.

- Integrated version control and change management to prevent costly errors.

- Seamless connection to design and manufacturing workflows, ensuring everyone works from the latest data.

Fusion doesn’t just manage data—it transforms how teams design, make, and collaborate. By combining PDM with design, manufacturing, electronics and integrated PLM, Fusion helps organizations move from disconnected processes to a fully integrated digital workflow that’s agile, efficient, and ready for the demands of modern manufacturing.

One tool. One source of truth. Endless possibilities for innovation. Get started today.