Adam “Abom79” Booth, shares how he blends manual skills, CNC, and Fusion to grow his shop and products, while also offering practical tips for other machine shops.

Adam Booth here, though some of you may know me online as Abom79. I’m a third‑generation machinist based in Pensacola, Florida, and the owner of a small but mighty job shop where old‑school manual machining and modern CNC live under the same roof. My work today combines repair and job‑shop projects, CNC production, product development, and educational content many of you have seen on my YouTube channel.

My roots in machining

I grew up in my family’s machine shop, sweeping chips and cleaning machines long before I ever stood in front of a lathe on my own. Over time I went from helper to full‑time machinist, learning the trade on manual lathes and mills and doing the kind of general industrial repair work that keeps local utilities, contractors, and small businesses moving. When my dad retired and sold off the largest equipment, I brought the remaining machines home and built the original “Abom79” home shop.

That home shop became the stage for my videos, where I share real jobs, real setups, and the thought process behind each cut. My long‑form videos turned into a resource not just for hobbyists, but also for colleges and technical schools that now use segments in their machining programs to show students what real‑world work looks like on the shop floor.

My CNC shop today

These days I’m running my own operation out of a dedicated space in a business park in Pensacola. On the manual side, I’ve got a Precision Matthews engine lathe, a KBC vertical mill, and a lot of well‑organized high‑speed‑steel tooling that’s perfect for traditional manual work. Alongside that is one of my favorite machines: an American Pacemaker wartime lathe that handles the heavy turning and pays tribute to the heritage I came from.

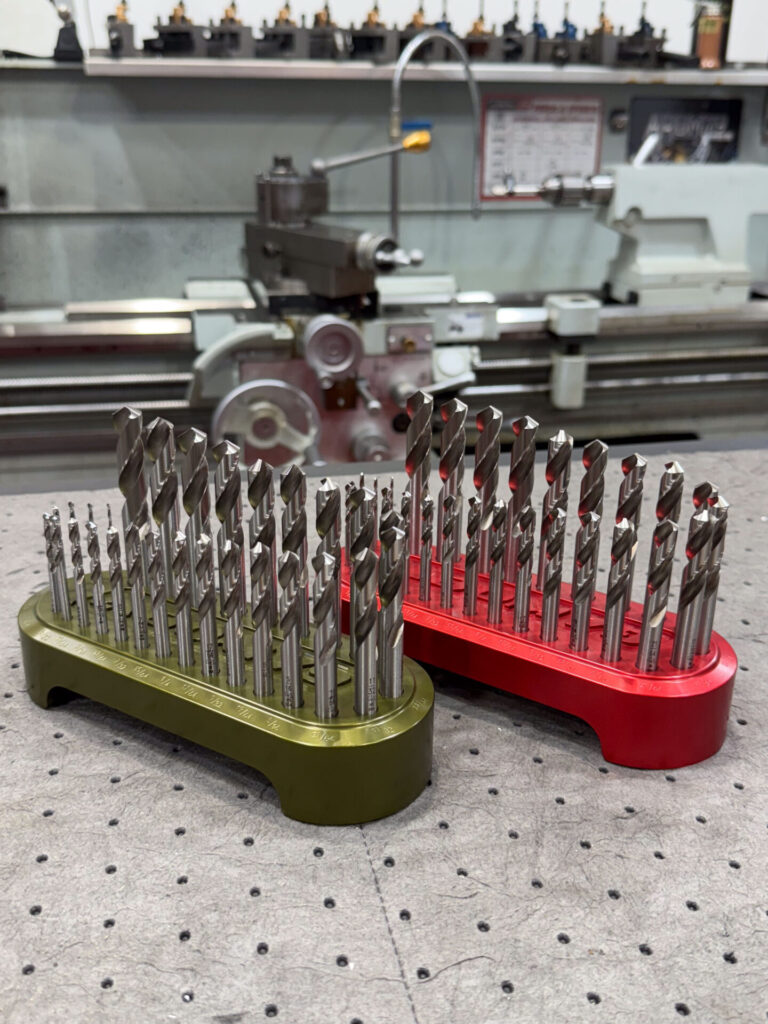

On the CNC side, the shop now includes vertical machining centers and a CNC lathe, supported by proper workholding, a jib crane, and the usual lineup of shop support gear. That mix of manual and CNC capability lets my company handle everything from one‑off repair and custom work to repeatable production jobs and branded products like my drill indexes, which are anodized and ready to ship.

Learning CNC and Fusion

For most of my life, I was purely a manual machinist. A few years back, I started to feel that if I didn’t learn CNC and modern CAD/CAM, I’d be left behind as the industry moved on. That’s what pushed me to expand into a new space and commit to CNC equipment and a new way of working.

Fusion is now at the heart of how I program my CNC work. I’ve been fortunate to learn Fusion with the help of my friend Kevin at Mechanical Advantage, who has been my coach and mentor on the software side. Together, we model parts correctly, pick the right toolpaths, and build workflows that make sense for a one‑man shop running real customer parts and products. Every new CNC project in my shop is another step in that learning journey, and I try to bring viewers along for that ride in my videos.

Recommendations to my fellow machinists

Whether you’re a manual machinist, or a one‑person shop or small business owner, here’s what I’d pass along from my own journey:

- Don’t be afraid to start small with CNC

- You don’t need a massive, fully loaded cell to get value from CNC. A single machine, good workholding, and solid fundamentals in Fusion can open a lot of doors.

- Use real jobs as your learning platform. Programming and running parts, you need to deliver is one of the fastest and most motivating ways to learn.

- Treat manual skills as an asset, not a limitation

- Strong manual fundamentals make you a better CNC machinist. Understanding how metal cuts, how tools behave, and how to indicate, measure, and fixture parts translates directly into better CAM and better results on the machine.

- Don’t abandon your manual machines. They shine on repairs, one‑off jobs, and situations where you need to move fast without programming overhead.

- Invest in organization and process

- Even in a one‑person shop, knowing where every tool lives and having a logical flow through the shop saves time and mistakes.

- Standardize your setups and tooling where you can. The more repeatable your workholding and processes are, the easier it is to scale from one‑off work into light production.

- Share what you’re doing

- Whether it’s social media posts, a YouTube channel, or just mentoring someone coming up behind you, sharing knowledge strengthens the trade and can create new opportunities for your business.

How to follow and work with me

If you’re interested in machining, shop tours, old iron, CNC, or just seeing how a modern one‑man shop runs day to day, you can visit our website, Abom79.com or find me on YouTube, Instagram and Facebook at Abom79. There you’ll see:

- In‑depth machining projects on both manual and CNC equipment

- Real repair and job‑shop work from my customers

- Product development and production runs of parts like my drill indexes

- Ongoing experiments and learning as I continue to grow my CNC and Fusion capabilities

The trade has a bright future for those willing to learn, adapt, and put in the work—and it’s an honor to play a small part in helping the next generation find their way into machining. I look forward to connecting with you.