This post is also available in: 日本語 (Japanese)

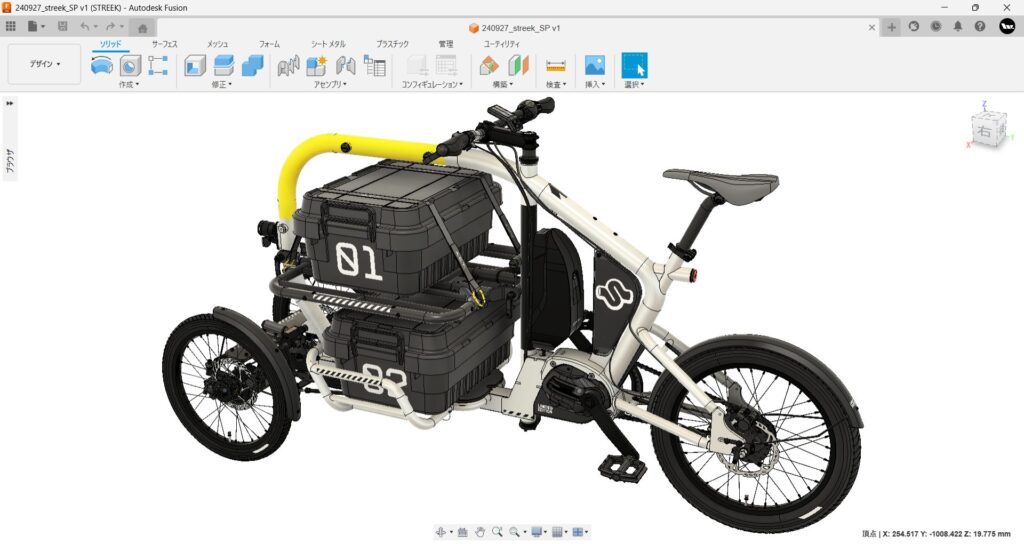

Who says bikes for hauling stuff can’t be stylish? Meet STREEK, an electric-assist tricycle that fits the footprint of a standard bike but packs a surprisingly large cargo space right in the center. It offers load capacity and stability that regular bikes just can’t match. The idea for STREEK was born back in 2016 when Takashi Okamoto, design project manager at Envision, wanted to create a bike he’d genuinely love to ride—something perfectly suited for Tokyo’s winding city streets.

He noticed that while cargo bikes are common in places like the Netherlands and Germany, Japan didn’t have anything quite like that. “There used to be handcarts here, but they just don’t work well in cities,” Okamoto explains. “So I thought, if there’s no cool, practical cargo bike in Japan, I’d better make one myself.”

The team took a grassroots approach, starting with miniature models of STREEK displayed alongside figurines at exhibitions. It quickly caught the community’s attention and built excitement inside the company about moving toward production.

From concept to a concrete product

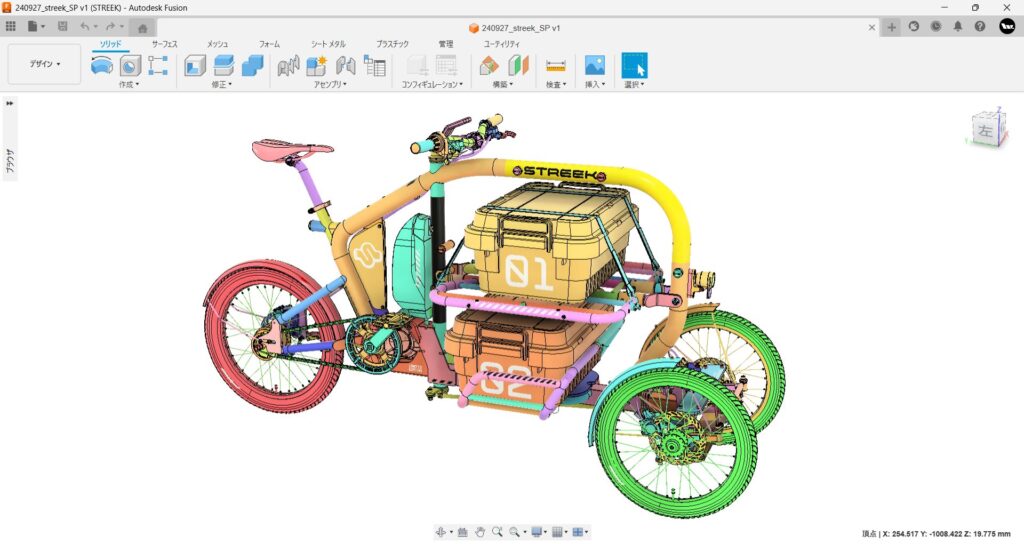

From those first sketches to the initial limited run, Okamoto was hands-on the whole way. The entire Envision team, including CEO Harry Uden, got behind the project. When it came time to pick design software, Okamoto, with a background in car design using Autodesk Alias and Rhino, chose Autodesk Fusion.

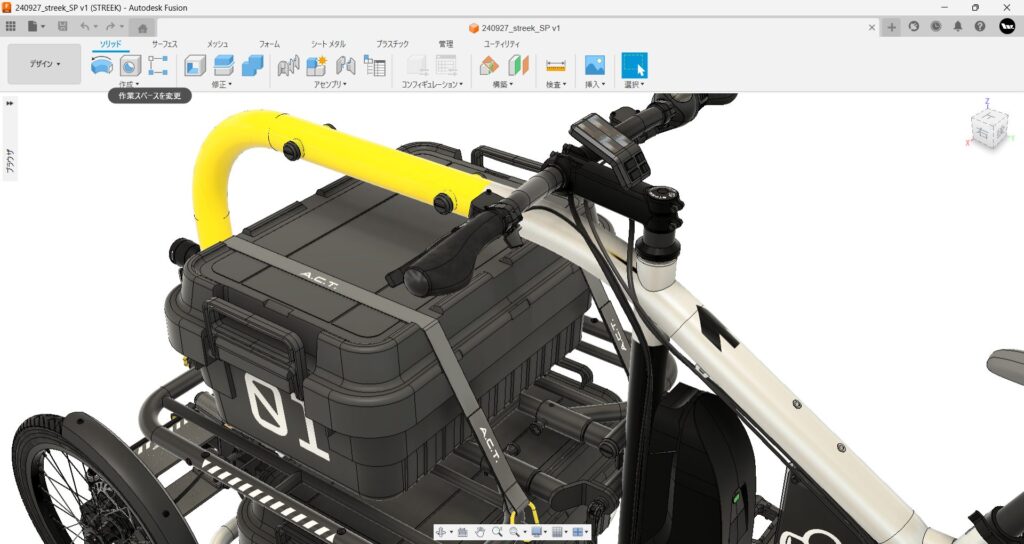

“For mobility products like bicycles, which are made up of many assembled parts, solid modeling is a better fit than surface modeling, which excels at large body shapes like automobiles,” he explains. “By using Fusion, which not only supports different modeling methods but also offers rendering and cloud-based data collaboration, every aspect of STREEK’s product development benefited. The operations and design work are intuitive, which made it possible to quickly turn ideas into form, and the rendering tools were both easy to use and high quality.”

Fujii Engineering, the company that helped bring STREEK from prototype to production, also leaned on Fusion and cloud collaboration to make teamwork smooth and efficient. “Without Fusion, STREEK wouldn’t exist as a product on the market,” says Okamoto.

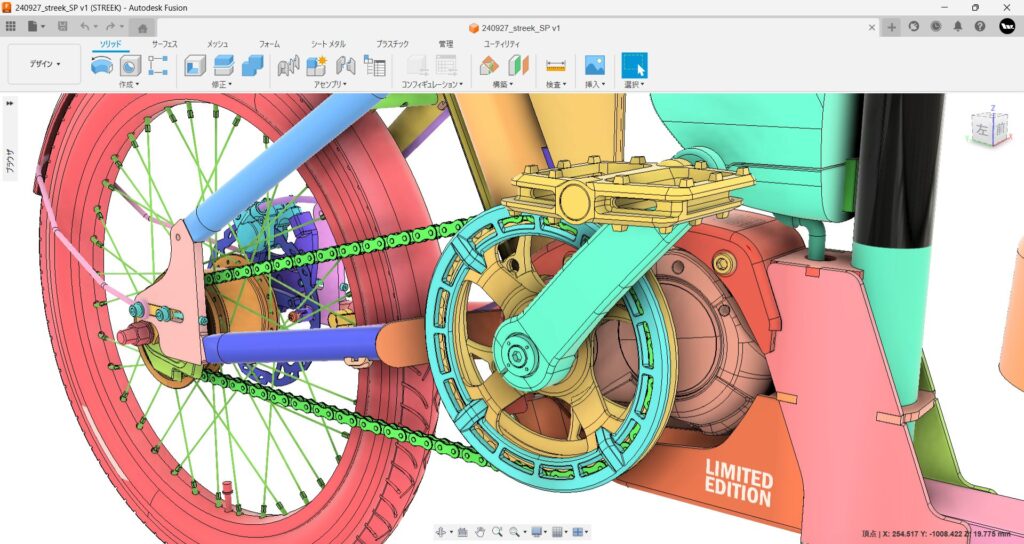

Solid models that connect directly to manufacturing

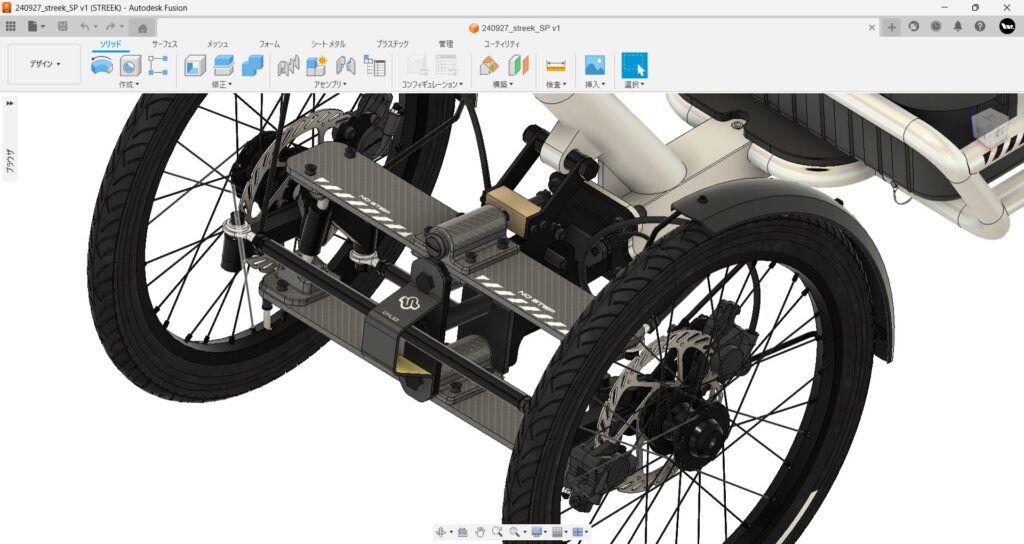

With solid modeling in Fusion, which makes it possible to build detailed, volumetric 3D models, the team could perform physical calculations such as mass, center of gravity, and moment of inertia at the design stage, while also reliably checking for interference between parts. The software also links smoothly to 3D printers and CAM, enabling a seamless handoff into manufacturing.

“To get people to take a product that doesn’t yet exist in the world seriously, it’s crucial to have visuals,” Okamoto says. “In order to get many people to connect with STREEK’s concept and overall image, modeling, rendering, and 3D printing in Fusion have, right from the design stage, served as tools for giving tangible form to the cargo bike and conveying its appeal.”

Prototyping and growing into production

The first 3D-printed prototypes created in Fusion caught a lot of attention at trade shows. That momentum led to working with a bike shop on customization and mechanical design, producing a rideable three-wheeler. The second version featured an original frame, and by the third, they designed a full cargo bike frame from scratch. Finally, the fourth prototype, finished in 2019, was built entirely in Fusion and included all the key features we see in STREEK today.

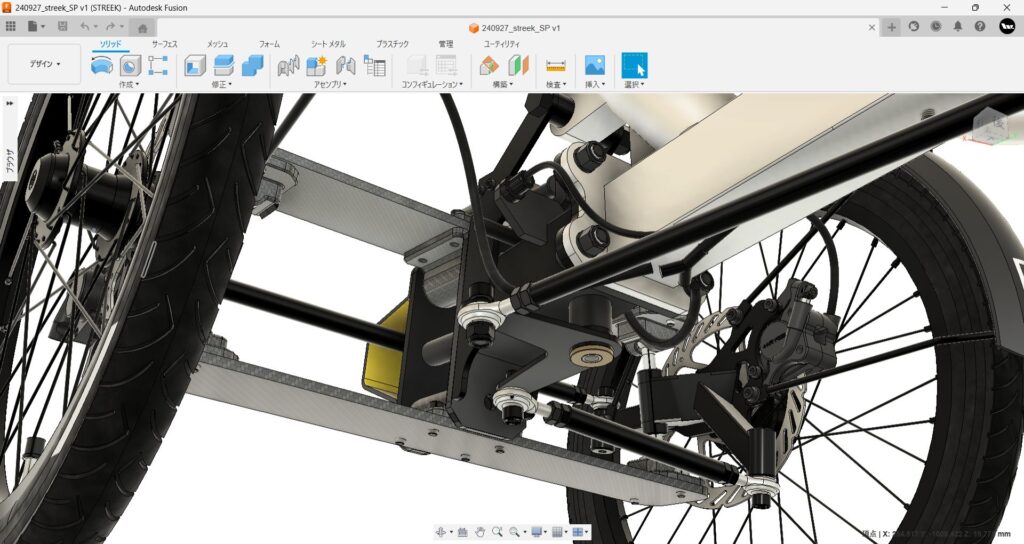

Along the way, the team needed to switch the front suspension to something simpler for mass production without losing ride quality. Around this time, Okamoto connected with Fujii Engineering’s president, Mitsuru Fujii, through social media.

Bringing scooter suspension expertise to STREEK

Fujii and his company had experience designing a three-wheeled electric scooter called Sunameri using Fusion since 2019. “We already knew about STREEK from the internet and were interested,” Fujii says. “When I got in touch on social media, I brought Sunameri to Envision, and we hit it off right away, moving quickly from casual chat to serious collaboration.”

The unique suspension developed for Sunameri turned out to be a perfect fit for solving STREEK’s challenges. Plus, since both companies used Fusion, sharing design data in the cloud was seamless. That’s how the team decided to join forces, with Fujii Engineering taking on everything from frame manufacturing to assembling the final product.

Learning Fusion fast and pushing STREEK forward

Sawa Arimizu, project lead at Fujii Engineering, joined the team in 2022. With a background in architecture, she hadn’t used Fusion before but picked it up quickly thanks to its intuitive solid modeling and helpful online forums. “Within about three months, I was using it practically,” she says.

Arimizu worked on improving the front suspension with carbon materials and even traveled to the factory in Malaysia to handle quality control. Because Fusion lets the team share data in real time via the cloud, STREEK can be produced anywhere in the world without losing the vision behind it.

Dreaming big with STREEK

STREEK’s success is the result of a clear vision brought to life through collaboration and innovative tools. “If I hadn’t found Fusion, STREEK might never have happened. It let me turn ideas into real images and find like-minded collaborators. The Mark 8 (current version) is already a high-quality mass-produced bike, but we’ll keep improving it so people on the street will continue saying, ‘That’s cool!’”