The worldwide demand for energy resources continues to climb exponentially. But the infrastructure is aging, and the need for continuous maintenance is increasingly challenging. Inspections are traditionally done by manned helicopters, and, far too often, there are dangerous crashes due to bad weather, dark conditions, and flying over unsafe areas. That’s where SwissDrones comes in with a solution.

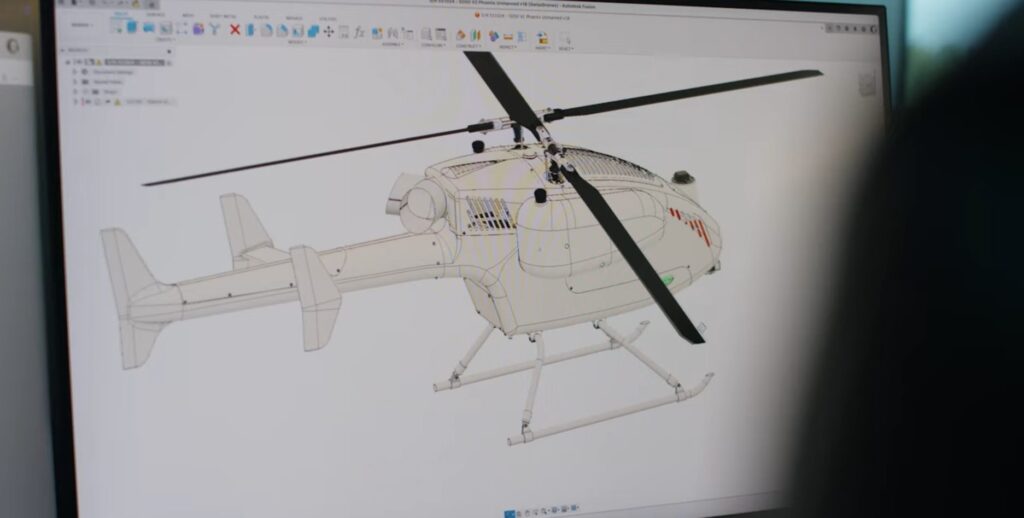

As a 50-person aerospace company headquartered in Zurich with manufacturing and engineering in Buchs, Switzerland, SwissDrones is reimagining what’s possible in aerial inspection. By replacing risky helicopter missions with uncrewed helicopters, they provide critical infrastructure inspections more safely, efficiently, and sustainably.

“We build unmanned helicopters that can precisely repeat flight routes,” says Pol-Victor Gisquet, Team Leader Mechanical Systems Integration and Aerospace Engineer, SwissDrones. “Using LIDAR payloads, it can map entire infrastructures and detect the slightest issues or shifts as small as one millimeter. It also reduces CO2 emissions by up to 90% [compared to manned helicopters].”

To reach these ambitious goals, SwissDrones relies on Autodesk Fusion to make it happen.

“The future of unmanned aircraft manufacturing will be even more data at a faster pace. With Fusion, we are ready for this. We can work at the quality of a big aerospace company more quickly and at a fraction of the cost.”

—Alex Lemus, Program Manager and Head of Airworthiness, SwissDrones

Reaching new heights with Autodesk Fusion

From the very beginning, it was important for the SwissDrones team to have a single point of truth and connect everyone from around the world.

“Fusion as a cloud solution offered a perfect fit,” Gisquet says. “We can start with not only engineering and design, but also continue with production maintenance and general configuration control within the same environment. This allows us to release a prototype at a much faster pace to the market while ensuring high quality and complying with aviation standards.”

Collaboration across teams is crucial. Fusion allows SwissDrones to view the most current view or even roll back the history if necessary. “We always have the latest and greatest model available, which facilitates communication between engineering, testing, production, logistics, you name it,” Gisquet says.

Accessing data with Fusion and Fusion Contributor

Of course, a key manufacturing requirement is exact and correct design data. With Fusion Contributor, SwissDrones can internally share URLs with technicians and engineers to ensure the assembly team works on the latest and correct models.

“Fusion Contributor allows us to share this huge data backbone throughout the team seamlessly,” Gisquet says. “Technicians and mechanics can work closely on the aircraft with their laptops or on any display monitors, accessing real-time design data and reducing the risk of error or wrong assembly.”

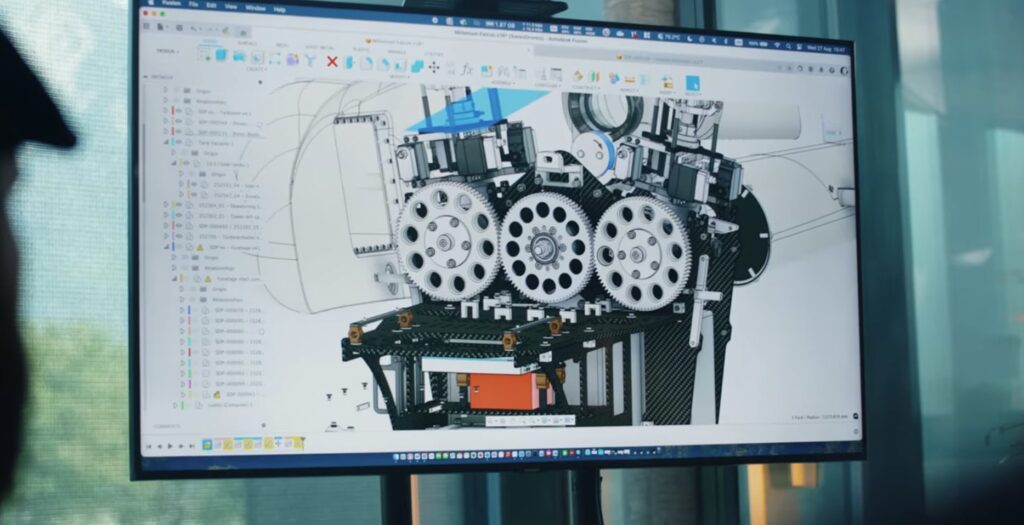

When it comes down to the actual manufacturing, the SwissDrones team is finding even more benefits with data and CAM integration in Fusion.

“We use CAM in Fusion to manufacture our carbon parts with our CNC machine,” Gisquet says. “This allows us to maximize the number of pieces we can get per plate, giving us better control over time and cost to meet the strict requirements in the aviation industry.

“To have a complete digital twin of the aircraft we need to show variant control. The PLM solution with the Autodesk Fusion Manage is at the heart of this process for us, and we are currently working on expanding it.”

—Pol-Victor Gisquet, Team Leader Mechanical Systems Integration and Aerospace Engineer, SwissDrones

Making an impact

With Fusion, SwissDrones can work at the speed of a startup with the ability to compete with the major players and leaders in the aerospace industry. At the same time, they are also keeping a much bigger vision in mind.

“We are really trying to make the world a better place, and cutting CO2 emissions is one of the key challenges of our time,” Gisquet says. “This motivates me, and I can have an impact to really try to improve our world.”