Back in 1988, Hawk Furniture first took off with a building on a former airfield in York, UK. Even the company name was inspired by the site that was previously used to build Hawk aircraft.

But Hawk Furniture’s products are decidedly different than the property’s heritage. As a family-based business for office furniture, 95 percent of their work is done in-house, all the way from design and manufacturing to shipping.

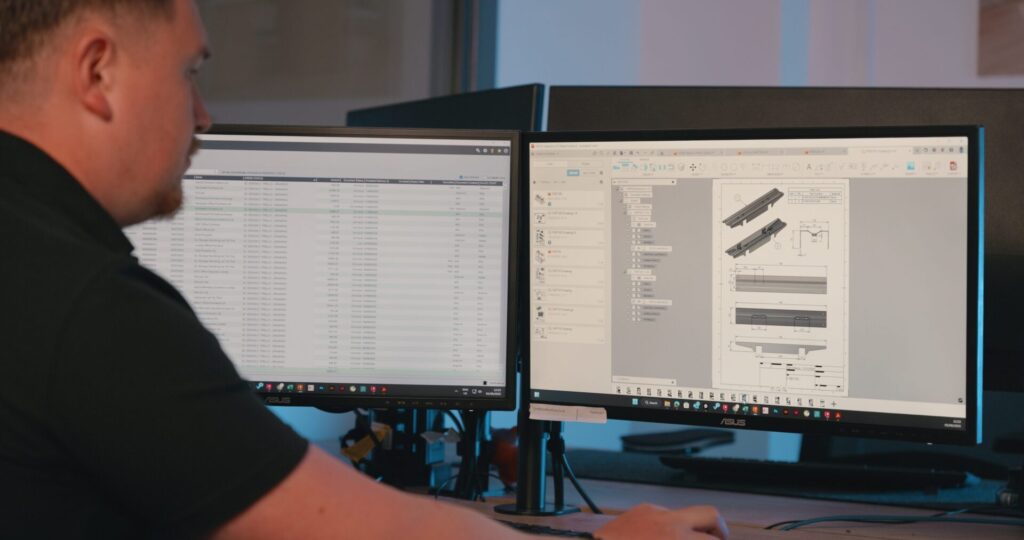

Now in the company’s second generation, they are focused on scaling the business even further and propelling new and updated products. With a switch to Autodesk Fusion, they’re making greater strides with time savings, accuracy, and creativity.

“Innovation and design are really important to us. It helps us make manufacturing more efficient and improve the end product.”

—Ben Appleyard, Operations Director, Hawk Furniture

New efficiency gains with Fusion

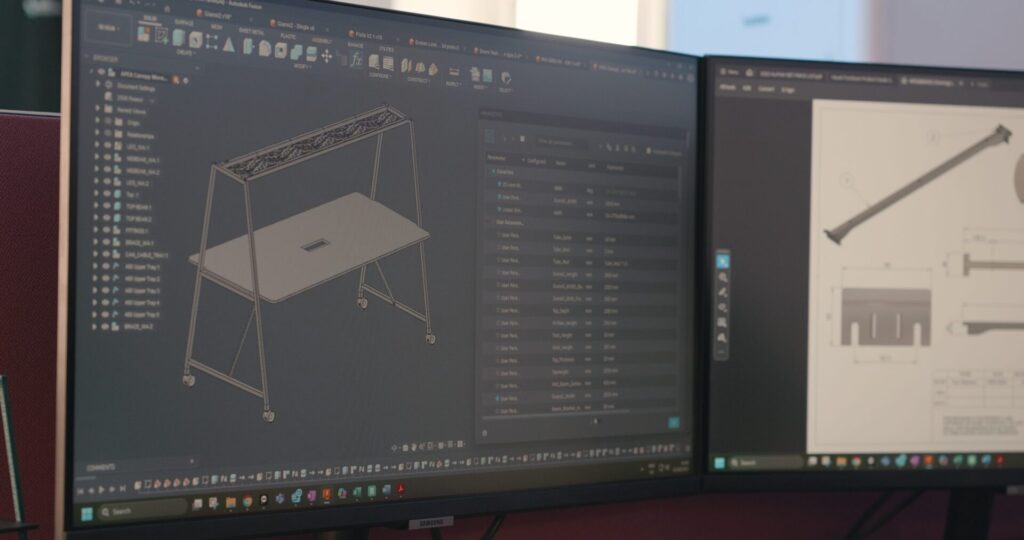

Half of Hawk Furniture’s business includes bespoke office furniture for its customers. By using parametric modeling in Fusion, the team can instantly adjust dimensions to meet a customer’s exact specifications. Instead of starting from scratch, they simply input the required measurements, and the design is generated immediately. This flexibility allows them to offer bespoke furniture while streamlining the design process.

Additionally, the team uses configurations in Fusion to create multiple versions of a product. “Configurations allows us to create all the configurations of a design in one file,” says Ben Tilford, design engineer, Hawk Furniture. “You just literally change it through a dropdown system.”

For design and manufacturing with sheet metal, they also eliminated previously time-consuming steps.

“We have a very bespoke cable tray design, so drawing that in 3D and then turning it into a flat sheet with sheet metal was so much handier [with Fusion],” says Tom Sheavyn, design engineer, Hawk Furniture. “Previously, we would have had to draw it in 3D, send that to the metal work department, and they would have had to make the flat part themselves. [Using Fusion], I’d say it saved up to a day and a half in testing.”

Collaborating in the cloud has brought even more transparency, especially throughout the entire design and manufacturing process.

“A game changer for Fusion is definitely the cloud-based system,” Tilford says. “It doesn’t matter what department you’re in, whether it’s the designers, someone coding, someone on the shop floor, or the directors. Anyone can look. It’s such a user-friendly layout and very easy to navigate through, so anyone can get the information they need. It’s all there.”

“In the past, we might have thought something would fit together. Only when we were building, we would realize something might be wrong. Using Fusion, we can find early problems. The parameters are set up in Fusion for our machines. We’ll know if it will work or not.”

—Tom Sheavyn, design engineer, Hawk Furniture

Driving new inroads with data

As Hawk Furniture moves toward more automated manufacturing, data has become important to drive this automation—and a big part of meeting that goal is with Fusion.

“We’re using Fusion to redesign basically our whole product database,” Tilford says. “Fusion’s a perfect tool to do it.”