InfoWorks ICM 2026 just achieved faster, very accurate simulations using a simplified mesh thanks to Subgrid Sampling. Let’s look at how we did it. But first, we need to understand the problem at hand.

The accuracy of hydraulic models has dramatically increased in recent years as innovations in hydraulic modeling solutions have put more and more power into our hands. However, as is often the case, with increased modeling accuracy comes slower simulation times because of the heavier computations that need to be performed.

The problem: When you shrink mesh size, run times increase

To begin with, higher model accuracy is usually accomplished by utilizing a finer mesh in your model. However, every time we shrink the mesh size in half to perform a typical hydraulic simulation, our run time can increase by a factor of 8! On the face of it, model accuracy seems to be inversely correlated to length of simulation times. So, is increasing one while decreasing the other even possible? Buckle up.

One way to speed up simulations is by offloading them to the cloud, running them often in parallel, on cloud computing infrastructure that is far more powerful than local machines. This is one of the main reasons Autodesk has innovated with cloud computing, now a part of all our desktop hydraulic modeling solutions. The cloud utilizes non-local machines to run the simulations, but it doesn’t reduce the overall compute load – it simply utilizes non-local machines to run the simulations. This improves the experience for you, the modeler, but it doesn’t make the hydraulic simulation more efficient overall.

Enter our newest innovation from InfoWorks ICM 2026: Subgrid Sampling. This new functionality allows for the use of larger mesh elements while still capturing highly detailed topographical changes in a surface. This means a larger mesh and a significantly faster simulation time in many scenarios. This can lead to up to a 65X increase in hydraulic simulation speed!

One way we’ve tackled this problem is by focusing the compute power on the parts of your surface that sees the most flow. This is where you care about accuracy the most.

How Subgrid Sampling works

Subgrid Sampling is a new feature that allows you to optionally use larger mesh elements in your model while still capturing highly accurate and detailed topographical changes in your surface. We’ve developed this using depth-volume variations within larger mesh elements to maintain the accuracy of a finer mesh. In some cases with flat sites, you might not need a fine mesh to capture the changes in topography. Therefore, you can speed up your hydraulic simulations quite nicely by reducing the complexity of your mesh by using coarse meshing.

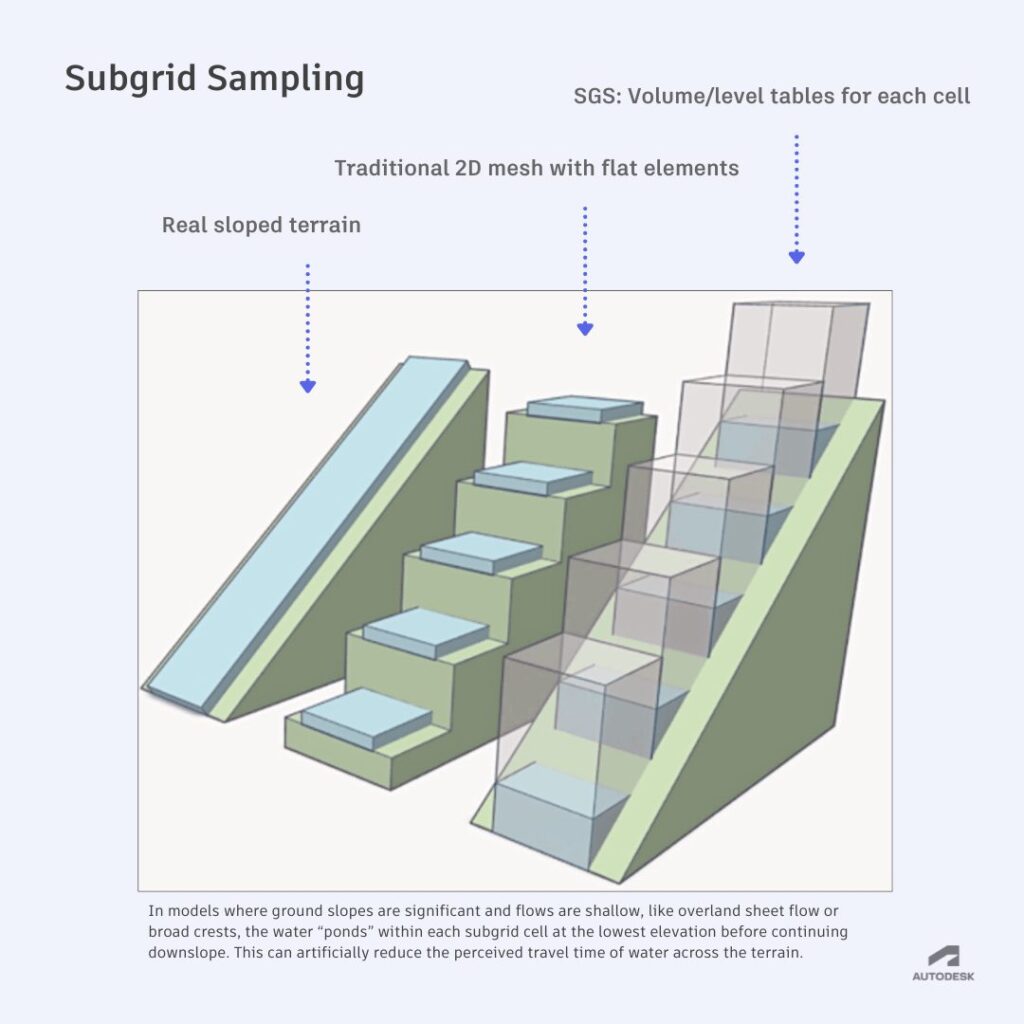

Conventionally, the 2D elements that are used to discretize the spatial domain and solve the SWE are considered flat surfaces. In other words, there is a single ground elevation for each 2D element, regardless of the underlying topography. Therefore, the topography becomes a series of stepped 2D elements, with the ground level for each 2D element calculated as an average value derived from the underlying ground model.

Subgrid Sampling enhances this topographic representation by:

- Using volume/level tables to represent the storage in each 2D element

- Refining topographic representation of the 2D element interfaces

As a stormwater nerd, I think there is some pretty cool math and engineering that goes into making this possible. The approach minimizes the digital footprint by avoiding the need for excessively detailed meshes, enabling users to run larger models for longer durations more efficiently, addressing a common product need for faster model simulations. If you want to hear more about the science and workflows, InfoWorks ICM Product Manager Samer Muhandes discusses this feature in greater detail in a webinar, How Autodesk is Shaping the Future of Stormwater, Wastewater, and Water Distribution.

Subgrid limitations

One specific limitation worth noting relates to how wave propagation speed is handled, especially on sloped surfaces with shallow flows. Because the Subgrid Sampling method relies on volume/level tables to define the storage capacity of each 2D element, this can sometimes cause the wave to appear to move faster than expected. Why does that matter? In models where ground slopes are significant and flows are shallow, like overland sheet flow or broad crests, the water “ponds” within each subgrid cell at the lowest elevation before continuing downslope. This can artificially reduce the perceived travel time of water across the terrain.

In the visualization above, the left-hand illustration represents a real sloped terrain with water flowing across it. The center shows a conventional 2D mesh with flat elements. On the right, it shows how Subgrid Sampling represents that same slope using volume/level tables for each cell. The result? Water tends to collect at the bottom of each subgrid cell before moving on, which can accelerate wave celerity. This phenomenon becomes especially relevant in flood risk assessments or shallow flow environments, where accurate timing and depth calculations are critical.

Get started with InfoWorks ICM 2026

- You can update your InfoWorks ICM app by visiting manage.autodesk.com.

- Read the What’s New product notes.

- Did you know? We have a YouTube playlist that compiles “The latest on InfoWorks ICM”? It’s a good resource for product update information.