Learn the fundamentals of geometric dimensioning and tolerancing (GD&T) and why it’s important for precision engineering. Discover how Autodesk Inventor streamlines GD&T applications for better manufacturing and quality control.

Enhance Your Engineering Workflows

Precise, powerful, and ready for innovation with Autodesk Inventor.

Manufacturing excellence relies upon precision, efficiency, and seamless communication between design and production. Every part, assembly, and mechanism—from aerospace components to everyday electronics—relies on consistent geometry and fit. This is where geometric dimensioning and tolerancing (GD&T) plays a transformative role.

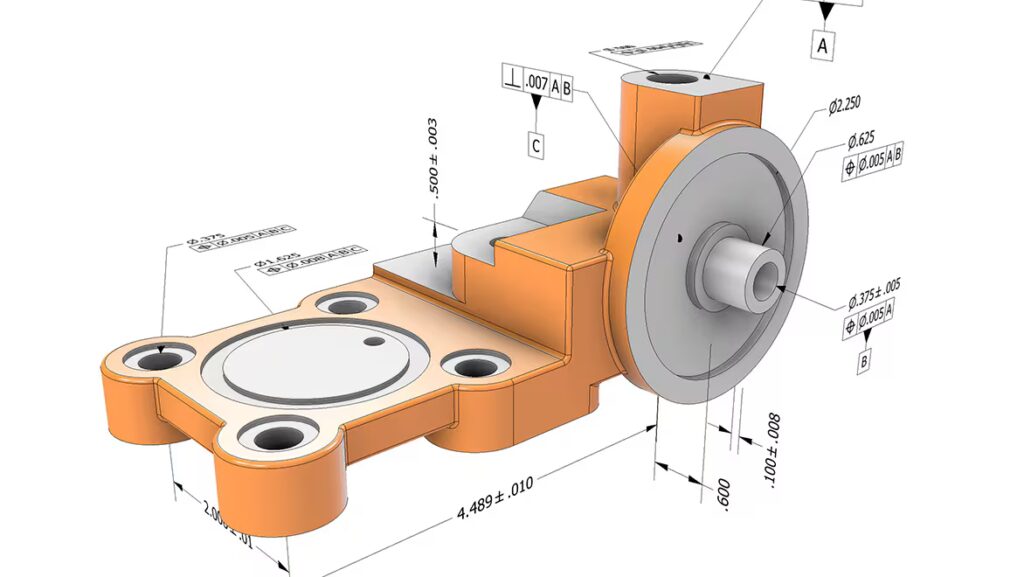

GD&T provides a universal engineering language that defines geometric relationships in a standardized way. Instead of relying only on linear dimensions, it specifies how shapes, tolerances, and datums interact to ensure performance and interchangeability. Today, with tools like Autodesk Inventor, these principles have evolved from 2D drawings to fully digital, model-based design environments.

Enhance Your Engineering Workflows

Precise, powerful, and ready for innovation with Autodesk Inventor.

The origins of GD&T: Solving wartime production challenges

The story of GD&T begins in the 1940s, during World War II—a time when complex machinery and rapid production exposed the limitations of traditional tolerancing. Engineers encountered a persistent problem: parts manufactured “within tolerance” often failed during assembly due to geometric misalignment.

At the Royal Torpedo Factory in Alexandria, Scotland, engineer Stanley Parker observed that perfectly dimensioned parts could still be functionally defective when assembled. He realized that linear tolerances didn’t capture how features interact in three-dimensional space. In response, Parker introduced a revolutionary idea: measure geometry relative to datums, allowing acceptable variation where it did not affect function.

The result was dramatic—reducing rejected parts, improving assembly efficiency, and optimizing inspection. Parker’s geometric framework laid the foundation for what would become GD&T, dramatically improving production results during wartime.

Standardization and global adoption

Following the war, industries worldwide recognized the potential of Parker’s method. By the 1950s and 60s, GD&T principles became embedded in engineering practice across sectors such as automotive, aerospace, and heavy equipment.

This movement led to the development of key standards:

- ASME Y14.5, first released in 1982 (and regularly updated), became the cornerstone for GD&T in North America.

- ISO 1101, its international counterpart, expanded adoption across Europe and Asia.

These frameworks unified terminology, symbols, and tolerancing methods. For the first time, engineering drawings worldwide could convey intent in a consistent and objective manner—regardless of language or region.

GD&T defined

GD&T is a structured symbolic system that ensures correct geometry for functionality. Traditional tolerancing simply prescribes allowable size deviations. GD&T goes further, controlling form, orientation, location, and profile based on how parts actually function together.

This system clarifies the allowable variation in:

- Form – ensuring flatness, circularity, or straightness.

- Orientation – managing parallelism, perpendicularity, and angularity.

- Location – controlling position, symmetry, and concentricity.

- Profile – defining complex surfaces.

- Runout – managing rotational deviations for balance and smooth motion.

By focusing on the function of each feature rather than arbitrary dimensional tightness, GD&T optimizes both precision and economy.

Datums: The backbone of GD&T

Datums establish a shared coordinate system for dimensioning. They define the fundamental reference planes, lines, or points from which all other measurements are derived.

For instance, in an automotive engine block, a mounting hole’s alignment to the crankshaft plane is critical. By assigning datums to key surfaces, GD&T ensures that these relationships remain consistent, even across global manufacturing networks.

Datums eliminate ambiguity in inspection and assembly, ensuring parts from one production batch will always fit parts from another. This consistency is crucial to achieving interchangeability in large-scale manufacturing.

Feature control frames for precision

A feature control frame communicates how a particular feature is to be measured and what variation is acceptable. It contains:

- A geometric characteristic symbol (e.g., position, flatness, perpendicularity)

- The tolerance value

- References to the relevant datums

For example, a positional tolerance frame stating that a hole center must stay within 0.05 mm of its true position relative to three datum planes guarantees accurate alignment without over-restricting manufacturing flexibility.

This elegant system transforms complex dimensional requirements into a compact, visual form readily understood across disciplines.

Why GD&T matters in modern manufacturing

GD&T bridges the gap between design intent and manufacturing reality. It enables teams to communicate not just what a feature should measure, but how it must function.

Key benefits include:

- Reduced ambiguity: Clear symbolic language minimizes misinterpretation.

- Improved interchangeability: Ensures parts from multiple suppliers fit together seamlessly.

- Optimized tolerances: Cuts unnecessary precision, reducing machining and inspection costs.

- Higher yield: Minimizes rework and scrap caused by unclear drawings.

- Enhanced global collaboration: Standardized symbols eliminate language barriers.

Industries like aerospace, automotive, and electronics rely on GD&T to maintain reliability where precision cannot be compromised.

The digital evolution of GD&T

By the 1980s and 1990s, CAD and CAM systems began integrating geometric tolerancing into digital models. The rise of coordinate measuring machines (CMMs) enabled automated inspection using GD&T data directly from CAD definitions, linking design and metrology for unprecedented accuracy.

In recent years, this integration has matured into model-based definition (MBD)—where tolerance information is embedded directly within a 3D model rather than in a separate 2D drawing.

MBD safeguards design intent throughout the digital lifecycle, from simulation to CNC machining and inspection. It eliminates manual reentry of dimensional data, drastically reducing errors while improving traceability.

Autodesk’s model-based design solutions exemplify this approach by embedding GD&T semantics into the same digital thread that drives manufacturing and quality inspection.

The role of training and standardization

For GD&T to fulfill its potential, teams must understand not only its rules but its purpose—functional design. Misuse or over-application can still create confusion and cost overruns.

Organizations like ASME, ISO, and the GDTP certification program set the benchmark for global competency in GD&T. Ongoing education ensures engineers interpret and apply tolerances consistently, particularly as standards evolve alongside digital manufacturing trends.

Modern CAD platforms also simplify adoption with guided annotation tools, real-time syntax validation, and built-in training aids—helping new users learn by doing.

Unlock Innovation with Fusion Manage: Your Cloud PLM Solution

Empower teams, simplify processes, and enhance collaboration.

How Autodesk Inventor powers GD&T workflows

Autodesk Inventor brings GD&T principles into a unified digital workflow—bridging 3D design, documentation, and manufacturing.

- Intelligent automation: Inventor enables users to apply GD&T symbols, datums, and feature control frames directly within 3D models. The annotations are associative, meaning any design change automatically updates linked tolerance data and 2D drawings.

- Standards compliance: Inventor fully supports both ASME Y14.5 and ISO 1101 standards, ensuring conformity for companies across regions. Built-in libraries guarantee that annotations meet official definitions and symbol structures.

- Digital collaboration: Because GD&T data lives inside the model, manufacturing partners can access it across connected workflows—CAM setups, inspection programming, and even CMM operations—without ambiguity or data loss.

- Tolerance analysis: Inventor’s Tolerance Analysis feature helps engineers understand how geometric variation affects assemblies. By running simulation-like studies, teams can predict fit, form, and function before cutting material.

- Integrated inspection: Inventor integrates with automated inspection systems, allowing GD&T data to inform measurement programs directly. Whether parts are inspected manually or by CMM, the digital tolerance definitions guide every step.

GD&T remains foundational to precision engineering. As manufacturing transitions fully into the digital era, its language continues to ensure that design intent translates perfectly to physical reality.

Autodesk Inventor empowers engineers to define, validate, and communicate tolerance information throughout connected, automated workflows.

Enhance Your Engineering Workflows

Precise, powerful, and ready for innovation with Autodesk Inventor.