This article explores how smart factories turn real-time data into business intelligence that drives efficiency and agility. It examines the technologies powering this transformation and how Autodesk solutions like Autodesk FlexSim and Fusion Operations enable manufacturers to optimize performance, sustainability, and profitability through connected digital systems.

Factory operators are converting traditional factories into “smart” facilities by integrating intelligent systems and real-time analytics into operations. Capable of self-optimization and rapid adaptation, smart factories unlock unprecedented levels of efficiency and responsiveness in the manufacturing sector. In an increasingly competitive global landscape, smart factories have become a new business imperative for all operators to embrace.

Digital foundation, intelligent factory

The basis of the smart factory is the Industrial Internet of Things (IIoT): a web of sensors scattered throughout equipment and facilities that constantly monitor machine performance, energy usage, and environmental conditions. All that data gets sent through cloud computing systems and powers the intelligence behind the whole operation. AI and machine learning algorithms then sift through these information streams to spot inefficiencies that would otherwise go unnoticed, figure out when equipment might need maintenance, and suggest ways to make processes run better.

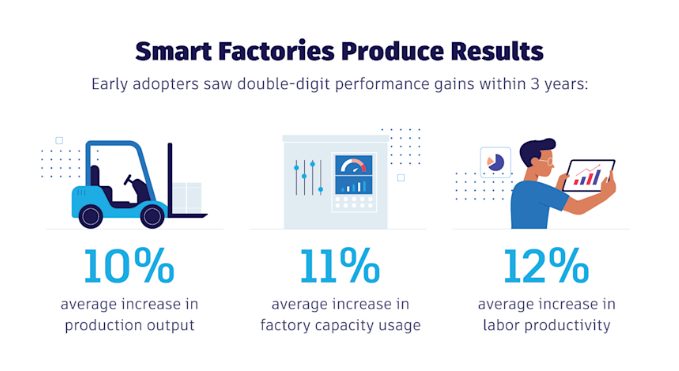

The results from this constant digital feedback are profound. According to a Deloitte report on smart factories, manufacturers who go all-in on these technologies typically see asset efficiency jump by 10-20%, product quality improve and waste drop by 10-30%, and labor and inventory costs fall by 20-30%. What makes this possible is a fundamental shift from reacting to problems to anticipating them. Rather than scrambling when a machine breaks down or a production line comes to a halt, a smart factory spots trouble and addresses it in advance.

A Deloitte study found significant improvements in factories that embraced “smart” technologies. (Source: Autodesk)

AI-driven insights take predictive maintenance even further to unlock dynamic scheduling and customer personalization. Machine learning models that analyze IIoT data can adjust production volumes on the fly to match demand as it shifts. This helps companies keep inventory lean and cut down on waste. These same systems also use computer vision to spot defects in components at a level of detail that would be impossible for human inspectors to achieve. As a result, products are safer and more reliable.

Equally as exciting is the digital twin: a virtual model of the physical factory that continuously synchronizes with real-world data. They allow engineers to simulate “what if” production, test design changes, and forecast energy use and emissions before implementation. The result is a more sustainable and efficient operation, where every decision is informed by comprehensive visibility.

Autodesk solutions for smart manufacturing

Turning the vision of the smart factory into reality requires a connected digital ecosystem that unifies design, production, and operations. Fortunately, Autodesk provides manufacturers with just the tools for the job.

FlexSim: 3D Discrete Event Simulation Software

Easy-to-use 3D simulation modeling and analysis software with high-end capabilities. Predict and optimize production processes with realistic 3D visuals and data-driven scenarios.

Autodesk FlexSim brings advanced factory simulation and digital twin capabilities to smart manufacturing. As a powerful modeling and analysis platform, FlexSim enables users to create detailed 3D simulations of production systems, allowing them to test workflows, identify bottlenecks, and quantify performance improvements before implementation. By modeling the interaction of machines, materials, and personnel, manufacturers can optimize layouts, forecast throughput, and reduce downtime—all while minimizing physical prototyping and disruption on the factory floor.

Fusion Operations: Manufacturing Insights at Your Fingertips

Fusion Operations provides real-time data to optimize scheduling, inventory, and quality.

Similarly, Autodesk Fusion Operations is a cloud-based manufacturing execution system (MES) that aggregates data from sensors, machines, and manual inputs on the shop floor to deliver complete visibility into production. By tracking operations, performance, and quality metrics in real time, Fusion Operations allows managers to adapt quickly to changing conditions and improve throughput. The platform’s analytics features provide actionable insights that drive continuous improvement.

Collectively, Autodesk’s suite of connected tools helps manufacturers close the loop between the digital and physical worlds. When digital design data flows directly into production systems through common data environments, collaboration improves and errors decrease. Engineers, operators, and managers share a unified view of the product and process, and every decision is aligned with measurable performance goals.

A new business imperative

Smart factories are changing the fundamental economics of manufacturing and how quickly companies can respond to shifts in the market. When businesses tap into digital technologies to collect, make sense of, and use real-time data, they become more responsive in ways that give them an edge over competitors. With platforms like Autodesk FlexSim and Fusion Operations, operators can make this transformation a reality.