Industrial automation, projected to reach $378.57 billion by 2030, is being transformed by IIoT, Industry 4.0, AI, edge computing, collaborative robots, and 5G. These technologies enhance real-time monitoring, predictive maintenance, and operational efficiency in manufacturing.

Industrial automation – key takeaways

- The industrial automation market is projected to reach $378.57 billion by 2030, growing at 10.8% CAGR from $206.33 billion in 2024.

- IIoT and Industry 4.0 technologies are driving interconnected manufacturing systems with real-time data monitoring and predictive maintenance capabilities.

- Collaborative robots (cobots) are making automation accessible to 93.4% of U.S. manufacturing firms with fewer than 100 employees.

- Edge computing combined with cloud platforms enables faster decision-making with reduced latency for industrial operations.

- AI-powered predictive analytics and cybersecurity solutions are becoming essential for maintaining competitive advantage and operational resilience.

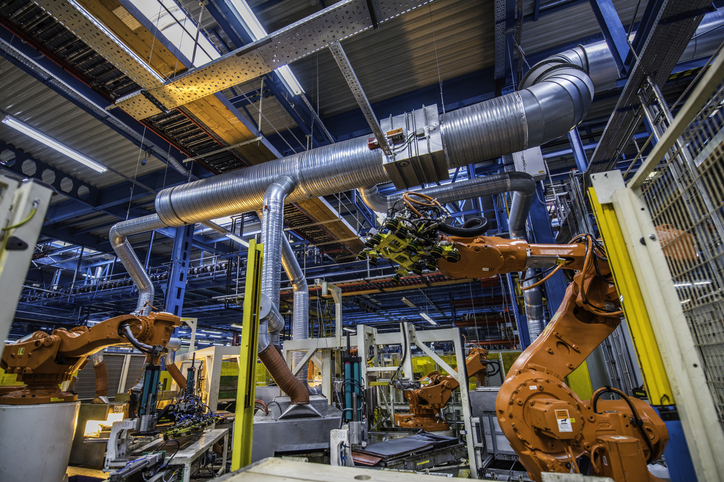

The manufacturing landscape is changing as emerging technologies reshape how companies approach production, efficiency, and competitiveness. Industrial automation has evolved far beyond simple mechanization. It encompasses sophisticated systems that use artificial intelligence, advanced analytics, and seamless device communication. With rising labor costs and the need to stay competitive in global markets, manufacturers are increasingly turning to automated solutions. They provide operational efficiency and the agility to adapt to changing market demands.

Industrial internet of things (IIoT) and Industry 4.0

The industrial internet of things serves as the nervous system of modern smart factories, connecting machines, sensors, and devices in an intricate network that enables real-time monitoring and data-driven decision-making. This ecosystem forms the foundation of Industry 4.0, where traditional industrial robots work alongside smart sensors and advanced analytics to create intelligent manufacturing operations.

Key technologies like OPC UA are establishing standardized protocols for device communication. It ensures that equipment from different manufacturers can work together seamlessly. Smart sensors collect data like temperature, vibration, and energy use. The information is gathered in real time, offering instant insights. It feeds straight into quality control systems. This lets teams make fast changes. As a result, they keep products consistent, waste less, and make factories run better.

The Asia Pacific region is leading market adoption, with over 39% of the global industrial internet of things market share in 2024. This growth is driven by massive infrastructure investments and government initiatives prioritizing digital transformation across manufacturing industries. Companies in sectors ranging from agriculture to wind energy are leveraging GPS connectivity and internet-enabled devices to optimize operations and reduce downtime.

Artificial intelligence and machine learning integration

Artificial intelligence and machine learning have emerged as game-changing technologies in industrial automation, changing how manufacturers approach everything from predictive maintenance to production optimization. These systems analyze vast datasets to predict equipment failures, optimize maintenance schedules, and continuously improve operational efficiency through adaptive learning algorithms.

Machine learning algorithms identify patterns in equipment performance data that human operators might miss. By analyzing historical maintenance records, sensor readings, and operational parameters, these systems can predict when machines are likely to fail and automatically schedule maintenance activities during planned downtime periods. This predictive maintenance approach helps companies avoid unexpected production interruptions while optimizing maintenance technician schedules.

Edge computing and cloud integration

Edge computing represents a critical advancement in how industrial systems process and manage data, bringing computational power directly to the source of data generation rather than relying entirely on remote cloud computing resources. This approach significantly reduces bandwidth usage and enables faster response times for time-sensitive industrial applications.

The combination of edge and cloud computing creates a powerful architecture that addresses the diverse needs of modern manufacturing operations. Edge devices process real-time data directly at machine sources. This enables immediate responses to changing conditions, while cloud platforms provide scalable storage and advanced analytics capabilities for long-term optimization and strategic planning.

This integrated approach is particularly beneficial for small and medium manufacturers who need cost-effective automation solutions that don’t require extensive infrastructure investments. By processing data locally through edge computing while leveraging cloud resources for complex analytics, these companies can access enterprise-level capabilities without the associated costs.

Advanced robotics and collaborative automation

Advanced robotics technology has evolved dramatically, with pick-and-place robots now excelling at high-speed, repetitive assembly and packaging tasks previously performed by human workers. These systems offer precision and consistency that traditional manual processes cannot match while operating continuously without fatigue or quality degradation.

Collaborative robots, commonly known as cobots, represent a significant advancement in industrial automation accessibility. Cobots are designed to work safely alongside humans without extensive safety infrastructure. This capability makes automation accessible to the 93.4% of U.S. manufacturing firms with fewer than 100 employees who previously couldn’t justify the costs of traditional robotic systems.

Autonomous mobile robots (AMRs) are transforming material transport and warehouse operations. These systems reduce the need for fixed conveyor systems and provide flexibility that traditional material handling solutions cannot offer.

5G connectivity and enhanced communication

The deployment of 5G technology is transforming industrial automation by providing lightning-fast download speeds of approximately 1 gigabyte per second. This enables real-time communication between devices that was previously impossible with traditional connectivity solutions. This enhanced bandwidth supports the massive data flows required for advanced automation technologies while reducing latency to near-zero levels.

Extended technology access to remote and rural areas opens new possibilities for agriculture and healthcare applications that rely on consistent, high-speed connectivity. GPS-dependent machinery, from precision farming equipment to autonomous vehicles, benefits significantly from the enhanced signal reliability that 5G networks provide.

Cybersecurity and data protection

The increased interconnectivity inherent in modern industrial automation creates new cybersecurity risks that data-dependent companies must address proactively. As production facilities become more connected through industrial internet of things implementations, the potential attack surface for malicious actors expands significantly.

GPS signal jamming and tampering represent emerging vulnerabilities that can affect connected machinery ranging from automated vehicles to precision manufacturing equipment. These attacks can disrupt operations without directly infiltrating company networks, making them particularly difficult to detect and prevent using traditional cybersecurity approaches.

Digital twins and building information modeling (BIM)

Digital twins technology enables real-time monitoring of equipment and facility conditions. The technology creates virtual representations that mirror the behavior and status of physical assets. This technology provides unprecedented visibility into system performance and enables predictive maintenance strategies that were previously impossible to implement effectively.

Building information modeling (BIM) helps manufacturers visualize facilities before construction begins. It helps identify potential layout conflicts and optimizing workflow patterns before significant capital investments are made. This capability reduces construction surprises and enables more efficient facility designs that support optimal automation implementation.

Autodesk digital factory solutions

As we examine the key automation trends shaping the industry, it becomes clear that the future belongs to organizations that can successfully integrate these advanced technologies while maintaining focus on their core business objectives. Companies can achieve this by implementing digital factory solutions, like those offered by Autodesk.

Enhance Your Engineering Workflows

Precise, powerful, and ready for innovation with Autodesk Inventor.

Autodesk Inventor

Inventor allows engineers to create detailed 3D models of mechanical parts and assemblies for precise design and prototyping. Parametric modeling and automation capabilities streamline the development of complex machinery, which is essential for customized automation solutions. By simulating mechanical operations virtually, Inventor helps identify and resolve potential issues before physical production. This ultimately reduces the time and costs associated with prototyping and manufacturing.

Autodesk Factory Design Utilities

Factory Design Utilities integrates with Autodesk Inventor to assist in planning and visualizing efficient factory layouts, optimizing space usage and workflow. These tools offer a collaborative environment where stakeholders can input their requirements and observe how various automation technologies will fit into the overall factory design. By creating digital twins of production facilities, manufacturers can anticipate and mitigate bottlenecks for smooth and efficient production processes.

FlexSim: 3D Discrete Event Simulation Software

Easy-to-use 3D simulation modeling and analysis software with high-end capabilities. Predict and optimize production processes with realistic 3D visuals and data-driven scenarios.

Autodesk FlexSim

FlexSim allows manufacturers to simulate and analyze various production scenarios, providing a dynamic environment to test and refine industrial processes before implementation. The software helps identify the most efficient workflows, resource allocations, and scheduling, which are vital for achieving optimal operational efficiency in automated environments. Manufacturers can visualize the impact of changes in real-time. This allows for data-driven decision-making that enhances adaptability and resilience in the face of evolving market demands.

Take the next step today to ensure you stay ahead in this rapidly evolving landscape.