TETMET’s Lattice Design Suite, integrated with Autodesk Fusion, enables AI-driven robotic welding to create large, efficient, lightweight lattice structures.

Elevate your design and manufacturing processes with Autodesk Fusion

Over the last few years, TETMET, a company based in Paris and Amsterdam, has focused on solving a key challenge – How to build large, lightweight metal or polymer lattice structures without the high costs, volume limitations, and material waste often seen in conventional manufacturing.

Their answer – Adaptive Spatial Lattice Manufacturing (ASLM).

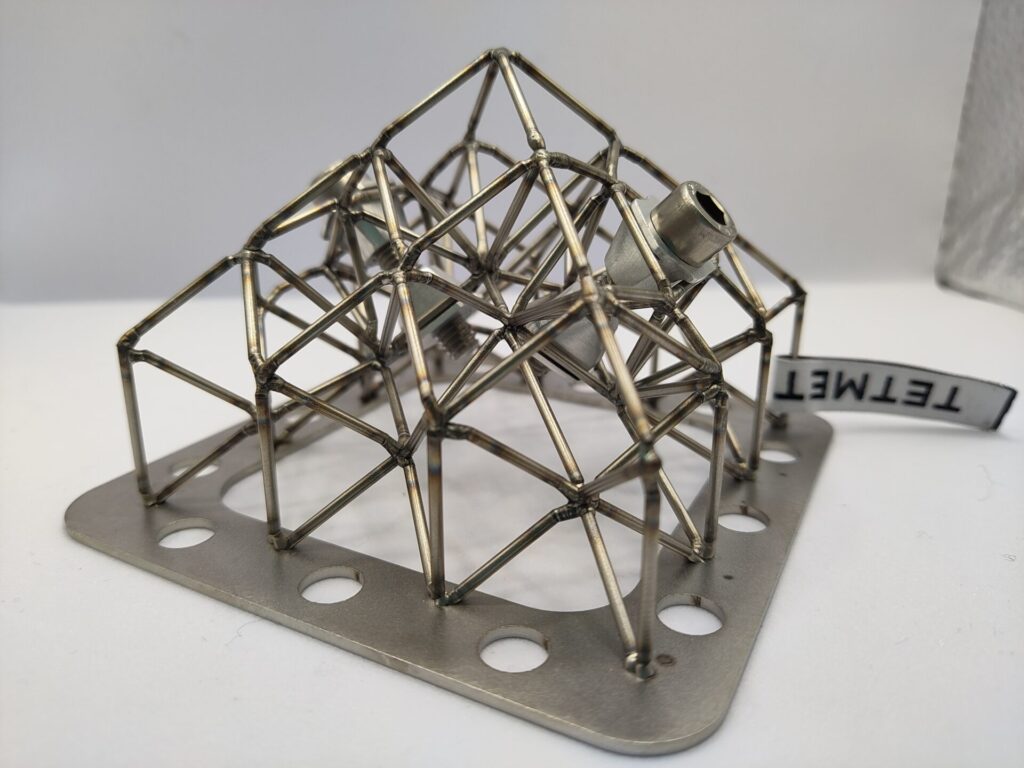

ASLM uses a robotic arm to autonomously weld small bars together in space to form 3D lattice webs of almost any arbitrary shape. A dedicated hard and software toolchain handles robot calibration, path planning, bar deposition and welding. This ensures the process stays accurate and repeatable. It’s one of those processes that’s genuinely mesmerizing to watch — the robot is basically “drawing” a structure in thin air.

What makes this so powerful is how it transforms concept we’ve known for over a century, such as trusses and lattice frameworks used in structures like bridges and the Eiffel Tower, into a digital, programmable, and AI-driven manufacturing process. Instead of being limited to what can be welded by hand or molded, you can now design lattices digitally. Robots then build these designs precisely, and at scale.

This opens a door to a new class of geometries: tall, wide, or simply complex parts that would be uneconomical (or impossible) with powder-bed AM, subtractive machining, or casting. For lightweight manufacturing, architecture, furniture, even energy-absorbing structures, additive spacial lattice manufacturing (ASLM) can drastically improve the cost structure. The robot only places material where the design actually needs it.

In its final vision, an ensemble of robots could assemble large structures of any shape, fully driven and coordinated by software.

The “Lattice Design Suite”

There’s one catch with a novel manufacturing process: your design habits need to change too.

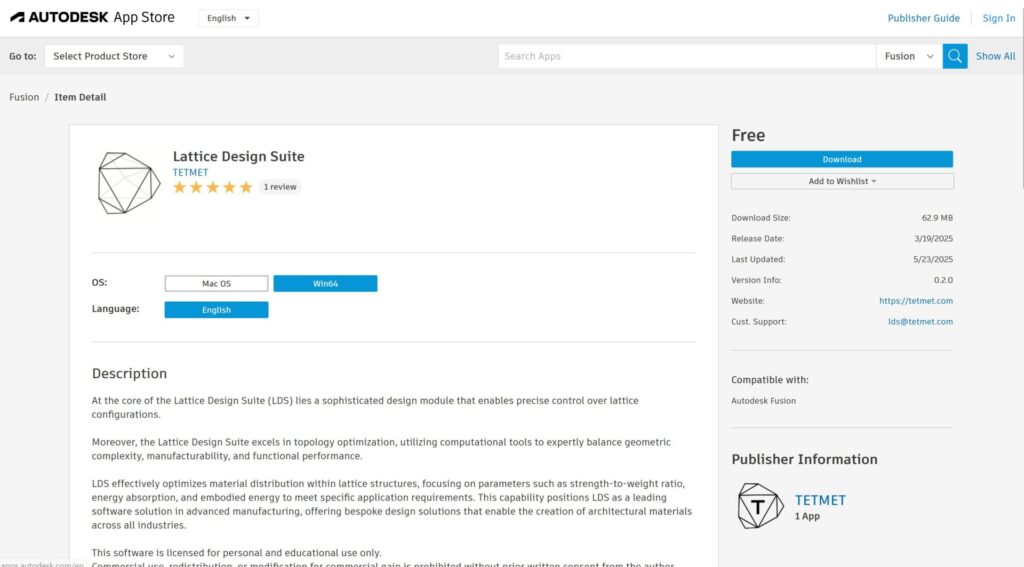

In order to take full advantage of this technology, traditional design and shape definitions have to be adapted to a proper design for the manufacturing workflow. In Autodesk Fusion, TETMET has found an ideal platform to build upon, and do just that.

Fusion offers extensive direct CAD modelling functionality, CAM capabilities, FEA simulation and much more. Affordably priced and equipped with a rich API, Fusion provides any technology developer a solid end-to-end solution from day one.

Download the Lattice Design Suite

The Lattice Design Suite is available in the Fusion App Store. If you don’t have a Fusion subscription, you can explore our plans and pricing options here.

Visit us at FormNext 2025

Please join the Autodesk team November 18-21 at booth E18 in hall 11.0 at Formnext 2025, the industry hub for additive manufacturing!

We will be displaying a variety of projects at our booth and demonstrating the latest additive manufacturing capabilities of Fusion.

TETMET lattice will be part of our exhibit, and you will have a chance to meet and talk to TETMET executives about their technology.