When Mitchell Lammering and Debrah Nijdam returned to Curaçao after studying product design in the Netherlands, they were struck by one thing: plastic waste everywhere—especially on the island’s beaches.

“We came back here and saw all this trash lying around… beaches full of plastic. The heaps were enormous,” Lammering recalls. “We started thinking of what we could do to use that material or make sure there’s less going back in the ocean.”

The sight inspired them to put their product design training to work, turning discarded plastics into new, functional products. Armed with design skills and determination, the pair began collecting scrap motors and steel from junkyards, building their first recycling machines—a shredder and a small extruder—by hand.

They didn’t have a way to process the recycled material into its new form, so they had to improvise. “We grabbed a big hole saw and drilled a hole in a piece of aluminum. That was our first mold,” Lammering says with a laugh. Those early molds produced simple coasters and keychains, which were the early foundations for what would become Limpi’s product line.

A short YouTube video of their work went viral, drawing local media and community interest. Media coverage and market demand quickly followed. Today, Limpi’s portfolio includes designing custom machinery, building site-specific work for well-known hospitality companies like Marriott, and more.

Designing more advanced molds

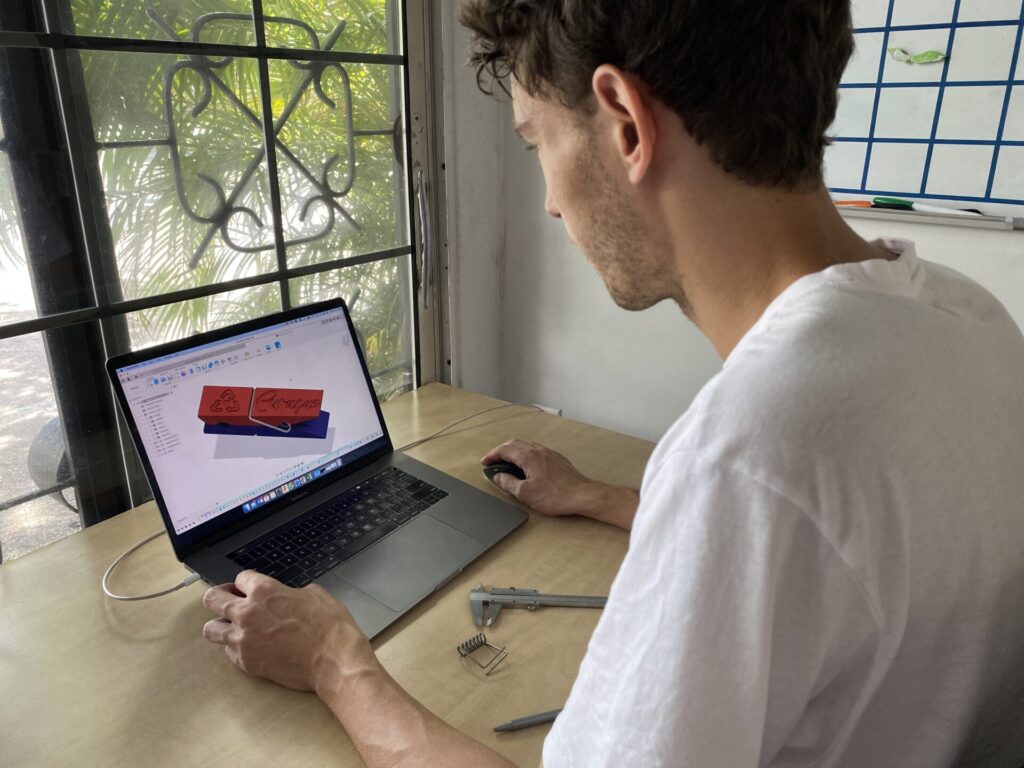

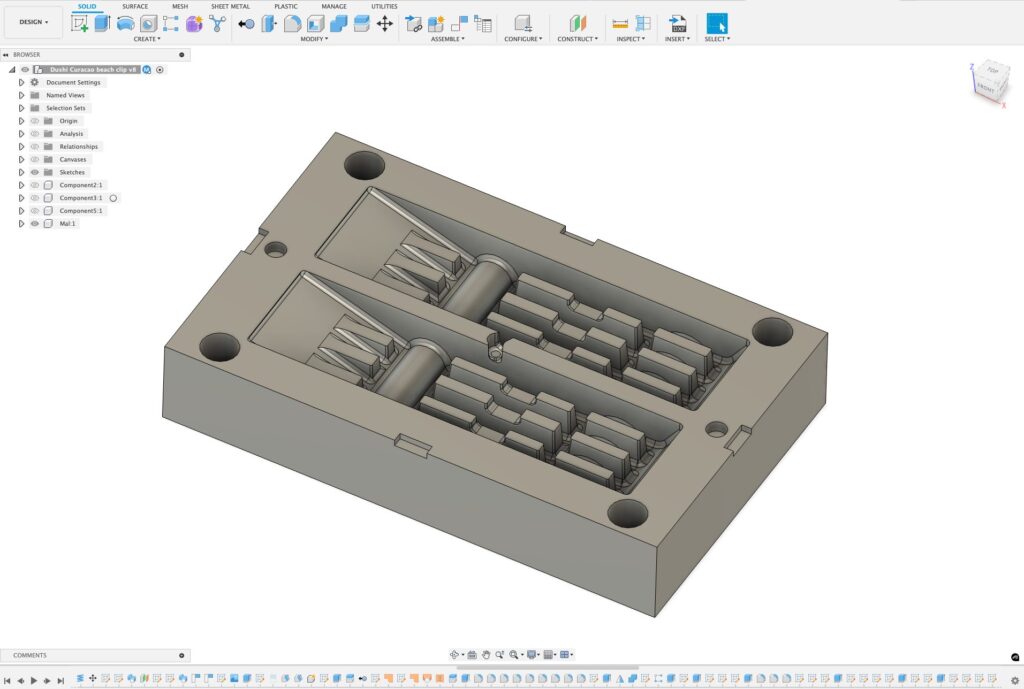

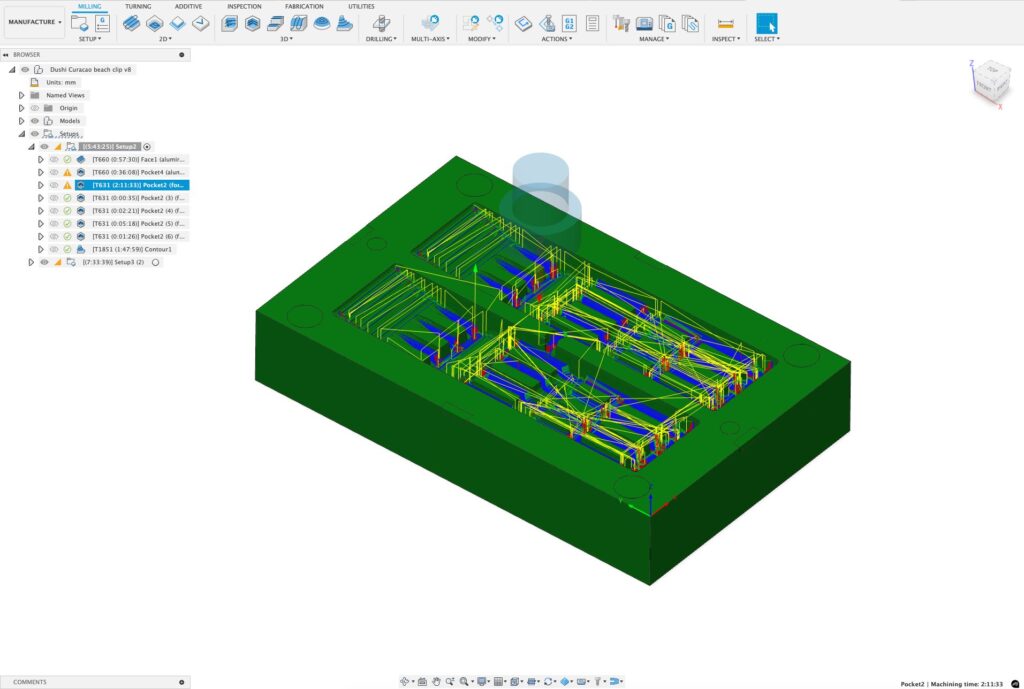

As Limpi’s designs became more complex, so did the need for tighter precision. The team began designing molds digitally, moving from SolidWorks to Autodesk Fusion. “We moved over to Fusion because it has CAD and CAM software available in one seamless platform, which we really like,” Lammering explains.

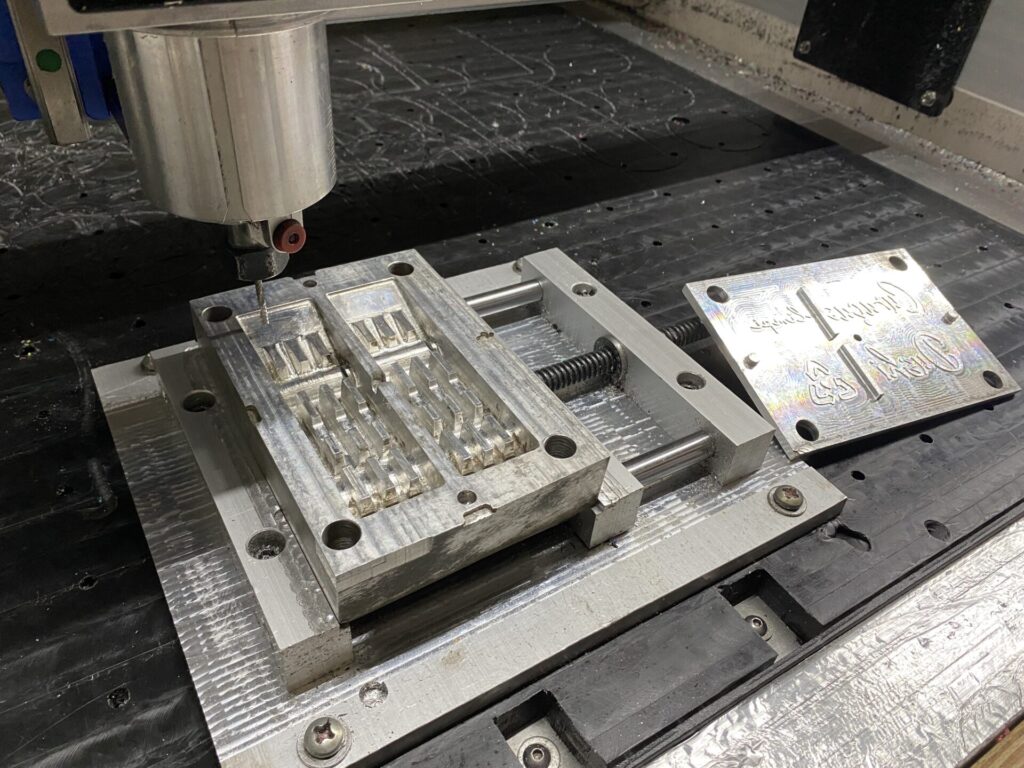

The integrated CAD/CAM features enabled Lammering to machine molds on their CNC setup without exporting between programs—streamlining an otherwise fragmented workflow. “I do most of the design on one computer, then I walk right across the shop to my CNC machine and keep the process going from there without fumbling through files or wasting any time,” Lammering notes.

Limpi used Fusion to design and manufacture custom aluminum molds for injection and casting—each one improving their understanding of radii, draft angles, and plastic flow. “You have to try it out, put the mold back in the machine, try it out again, make some changes—every part we made was a new learning curve,” Lammering says. Limpi advanced from 2D engravings to fully 3D designs, introducing complex forms, smooth patterns, and precise fit for injection molds while giving their recycled products new depth and polish.

After one grueling order of 2,500 keychains was made entirely using the manual injection device, the team used Fusion to design their first hydraulic injection machine. “We were literally standing on the manual machine to apply the right level of pressure and inject plastic. After that, we said, ‘never again,’ and designed a hydraulic one in Fusion,” says Lammering.

That machine, still in use today, introduced adjustable pressure and consistency that manual machines couldn’t match, marking a turning point in Limpi’s production capability and consistency while laying the foundation for scaling production.

Putting the recycling process on full display

Limpi eventually outgrew its backyard workspace. Piles of shredded plastic and expanding machinery filled every corner until the team migrated to their new home inside Curaçao’s Sambil Mall. “Now we have a 500-square-meter facility in the mall, so people can see through the window and see exactly what we’re doing all day,” Lammering says.

The new space not only improved working conditions (thanks to air conditioning and ample room) but also brought the public directly into the process. “The hardest part for us when telling our story is getting people to truly understand the scale of what we do. If we just tell them, they simply nod their heads. Having them here shows a whole different picture of what it actually takes and what we can do with that plastic bottle they just threw away,” Lammering says.

Visitors now watch the full recycling process—shredding, melting, molding—and often leave with a product made from waste collected on local beaches. “The public engagement is just as valuable as the production itself,” Lammering notes.

Designing for the hospitality industry

When the local Marriott resort sought eco-friendly art for its guest rooms, Limpi delivered. “We created wall art out of ocean waste—fish, turtles, and starfish that were lit up from behind—and Marriott ordered over 400 pieces,” Lammering says.

Each design begins as a 2D sketch. “It’s up to me to take those sketches and create the 3D design in Fusion,” says Lammering. “We then send the digital concept off to our customer to see if they like the product. We’ll often even 3D print the concept model before we begin making the actual mold.”

The entire process only lasts a matter of days, not weeks, allowing Limpi to quickly deliver recycled products to meet customer needs. “One time we did it all in two days! From confirming the concept, to designing and creating the mold, all the way through to completing our production run. It can be very fast,” Lammering adds.

Empowering youth through recycled design

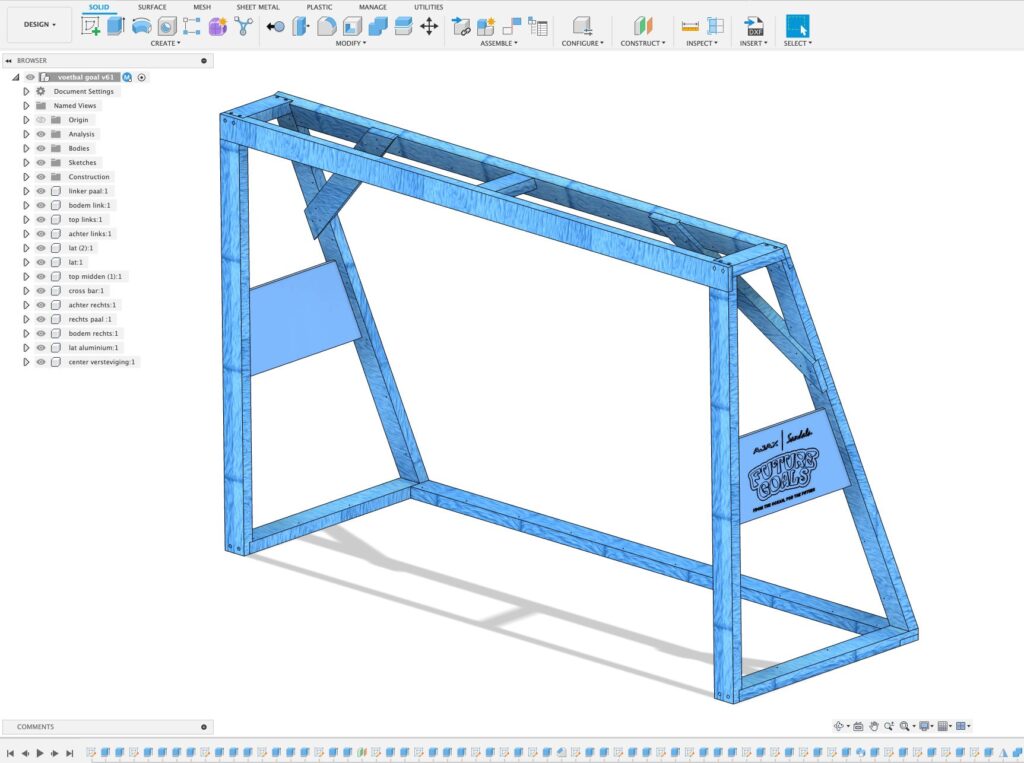

Limpi also plays a central role in the Future Goals program, a partnership between the Sandals Foundation and the Ajax Football Club that turns recycled plastic into soccer goals and other accessories for primary schools in the Caribbean. Sandals sponsored and supplied the first machine for goalpost creation with Limpi as the production partner. The program aims to enrich the education and development of youth across Curaçao and beyond.

“The Future Goals program alone has recycled around 6,500 pounds of plastic (that’s around 1.5 million bottle caps) and produced over 70 goalposts for schools,” Lammering reports. The project’s success has inspired expansion to Jamaica and other islands, supported by sponsors and local governments. Each goal, frame, and trophy serves not just as a recycled product but as a lesson in sustainability and design.

Limpi has evolved from a small experiment into a regional model for sustainable manufacturing and will continue refining its machines, molds, and mission. Looking ahead, the company aims to replicate its recycling model across the Caribbean, starting with Aruba, Bonaire, and St. Martin. “Our future vision is to take the same system and machines we created and replicate them on other islands. We want to become the leading sustainable plastics recycling company in the Caribbean.”