Boost your manufacturing efficiency with Autodesk Fusion and Kennametal tooling to streamline workflows, optimize machining, and produce high-quality parts with confidence.

Elevate your design and manufacturing processes with Autodesk Fusion

For machinists and manufacturers, every decision—from tool selection to programming speed—can make or break productivity. Integrating Autodesk Fusion with Kennametal tooling is a game-changer. This powerful combination is designed to enhance your processes, reduce costs, and help you produce higher-quality parts with confidence. Let’s take a look at how Fusion and Kennametal can elevate your manufacturing operations.

Optimizing CAM operations for real-world results with Fusion and Kennametal

Picture this – walking into your shop knowing you’ve already addressed potential machining issues before the first cut. With Fusion, you can create realistic CAM simulations that let you visualize every step of your process. Whether you’re working with 3-axis, 4-axis, or 5-axis machines, Fusion’s intuitive enhances your workflows through toolpath creation, collision detection, and material removal strategies.

By simulating your operations in Fusion, you can identify and resolve issues like tool collisions, inefficient toolpaths, or excessive material left on the part. The result – more time, less scrap, and less mistakes.

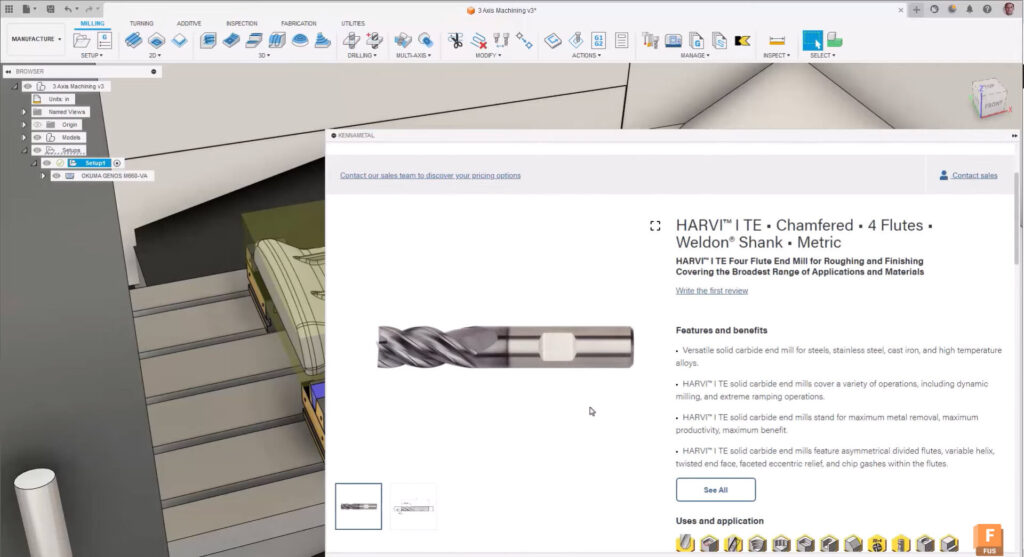

When you pair Fusion with Kennametal tooling, you seamlessly gain access to a vast library of proven tools. Since the Kennametal app integrates into your Fusion environment, you’ll no longer need to spend hours searching through catalogs or guessing which tool to use. You can select the optimal tool for your application with just a few clicks. The app even helps you configure tool parameters, so you’re always ready to machine with confidence.

Mastering speeds and feeds for maximum efficiency

Speeds and feeds are critical for any successful machining operation. Get them right, and you’ll see improved tool life, better surface finishes, and faster cycle times. Get them wrong, and you risk tool breakage, poor part quality, and unnecessary downtime. With Fusion and Kennametal’s data-driven recommendations, you no longer need to rely on guesswork or outdated charts.

The integration gives you access to up-to-date cutting data for a wide range of materials and applications. You’ll receive smart suggestions for optimal speeds, feeds, and depth of cut, tailored to your specific tool and material. Now you can optimize your machining plans but also improves inventory management by reducing the risk of tool overuse or premature failure.

Understanding the points of contact in your milling operations is also important. The advanced simulation tools in Fusion let you visualize how your tool interacts with the workpiece. You’ll spend less time troubleshooting, get more consistent results, and maintain a smoother workflow from start to finish.

Reclaiming your time and streamlining workflows

No one enjoys spending hours looking for the right tool or manually inputting data. With Fusion and Kennametal tooling, you can automate and streamline these routine tasks. This frees up your time so you can focus on what really matters —making parts.

Th automation features in Fusion allow you to quickly generate toolpaths, set up jobs, and manage your tool library. The Kennametal app provides instant access to tool data, so you can focus on machining instead of paperwork. Together, these tools help you work smarter, not harder.

By reducing the time spent on manual tasks, you’ll be able to take on more jobs, meet tighter deadlines, and keep your shop running smoothly. You’ll also realize lower costs, as optimized toolpaths and better tool selection mean less tool wear and fewer replacements. Plus, with fewer errors and less rework, you’ll consistently deliver high-quality parts to your customers.

Ready to transform your shop with Fusion and Kennametal?

The collaboration between Autodesk Fusion and Kennametal tooling is more than just a software and hardware solution—it’s a pathway to transforming your manufacturing operation

Whether you’re running a small job shop or a large production facility, Autodesk Fusion and Kennametal tooling give you the edge you need to stay competitive in today’s market. You’ll be able to take on more complex projects, deliver faster turnaround times, and exceed customer expectations.