For astrophotographers Jeff Geiss and Rick Bassham, a night under the stars once meant hauling heavy equipment, reassembling complex rigs, and hoping everything aligned before dawn.

“We’d have to pack boxes and crates in a car, drive way out in the middle of nowhere, set up tripods and equipment, and then try to get everything to work,” Geiss recalls. “There were no guarantees because you have to reassemble everything each time.”

To eliminate that frustration, they built their own “roll-off roof” observatory—one that could house a telescope permanently and run entirely remotely. When others began asking for similar systems, a business was born.

In 2022, Dark Dragons Astronomy (DDA) officially launched to bring professional-grade automation to its customers. DDA’s clients range from educational institutions and research facilities to serious astrophotographers operating permanent remote installations. Each project shares the same goal: combining mechanical reliability, electrical precision, and software control into a seamless observatory experience.

From concept to field-tested reality

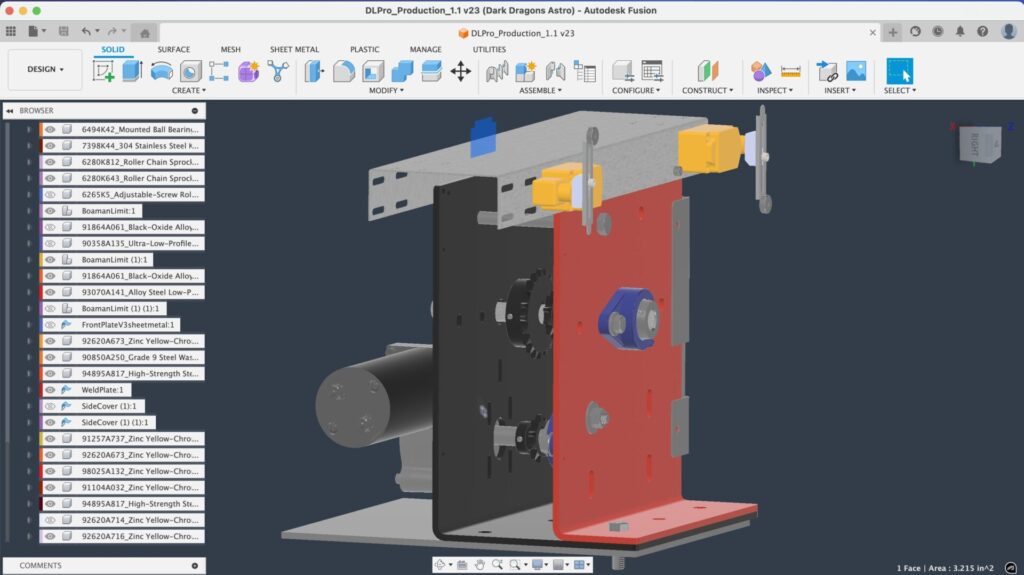

When Geiss and Bassham decided to design the mechanical systems themselves, they turned to Autodesk Fusion. Its accessible interface and cloud-based collaboration suited their business perfectly.

“We modeled our entire observatory in Fusion. Every stud, every hinge—even the roof motion,” Bassham explains. “We did all of that before we ever purchased a single piece of lumber.”

Beyond mechanical design, Bassham also engineers the in-house PCB controllers and embedded firmware that power DDA’s automation systems. He then integrates electronics seamlessly with each Fusion assembly.

Geiss and Bassham can both review, iterate, and visualize designs together using Fusion. While Bassham leverages Fusion to export STEP files for electronic components, Geiss uses it to design enclosures, mounts, and drive systems. When it’s time to merge electronics and mechanics, Fusion offers an ideal collaborative environment that allows for rapid, real-time feedback.

“Jeff will send me the Fusion designs to get a second set of eyes,” Bassham says. “We can both work in the same file at the same time, so it’s effortless.”

Once finalized, exporting the completed STEP files is simple. Geiss exports the files and sends them off to a small-batch manufacturer such as OSH Cut for fabrication. Instant quoting and automated laser cutting turn virtual models into physical parts in days instead of weeks.

Repairable designs powered by Fusion and McMaster-Carr

Many of DDA’s customers operate in remote, often harsh environments where maintenance calls are costly and downtime unacceptable.

“We determined early on that we want our mechanical components to be simple, reliable, and repairable,” says Geiss. “Fusion helps us design components that even a local operator can repair or replace with common tools—where a service call could take weeks or be impossible.”

Fusion’s integration with McMaster-Carr supports that mission of reliability and repairability, allowing DDA to seamlessly integrate standardized, high-quality parts into their designs.

“Our designs are all incredibly reliable, and that’s where Fusion’s McMaster-Carr integration really makes an impact,” says Bassham. “We can pull those parts directly into our models while we design and have 100% confidence that they’ll fit and work perfectly.”

It’s also a major benefit for their customers. “We can have the exact replacement parts shipped to a site in just a few days,” Geiss adds. “If I need to replace a bearing in the field, I just look at my McMaster-Carr order for that job, reorder the same part, and have it shipped directly to the customer.”

Each system is engineered for remote, extreme conditions, from high-altitude snow to desert heat, so customers can maintain uptime without on-site service. It’s not just automation—it’s mission-grade reliability.

Bringing reliable automation to one of the oldest sciences

Dark Dragons Astronomy is bringing industrial-grade automation to astronomy—one of the world’s oldest scientific fields. A great example is their work with Howling Coyote Remote Observatories (HCRO) in New Mexico. HCRO’s large Quonset-style enclosures—built by Henson Industries—house a dozen telescopes or more under massive, motorized roofs that protect equipment from the elements. When the original third-party gate-motor system failed under load, DDA stepped in to engineer a custom drive and control retrofit.

“We used Fusion to design several different gear sets so we could change gear ratios on the fly while we were on site,” Geiss explains. Designed in Fusion and delivered in under six weeks, the new system powers 7,000-lb roofs flawlessly, even through wind and snow.

Another standout project is this year’s automation retrofit for Queensborough Community College in New York City. Previously outdated and with no automation capabilities, the 1970s-era dome now operates entirely by remote control.

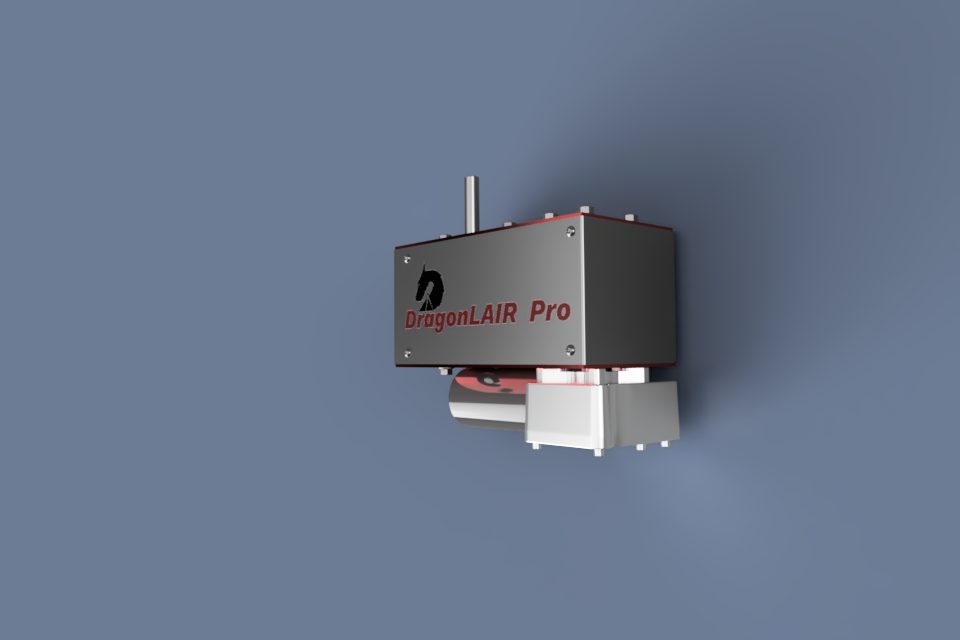

“The modeling we did in Fusion worked really well for this project, and it was so easy for us to do,” says Geiss. “We went from idea to installation in just eight weeks. There’s no tool other than Fusion that would have enabled this kind of speed to deliver a customized, working product.”

“The prototype we designed in Fusion ultimately became the production housing in 10 days,” Geiss recalls. “When we got the physical product back from OSH Cut, it was exact. We just bolted it on and used it—the first one worked perfectly.”

After learning about the opportunity in April, DDA leveraged Fusion’s rapid prototype-to-production capabilities to deliver a full-scale automation system by mid-June. “The students there now have access to high-end optics they can run directly from inside the library,” Geiss adds.

Empowering the maker and education community

Fusion also empowers DDA’s community outreach. Dark Dragons released an open-source design for a small backyard observatory called the Mini Lair, now available for free download. “You can build it for less than $1000 in lumber if you’ve got the skills,” Bassham notes. By making these plans freely accessible, Dark Dragons is giving DIY enthusiasts, students, and educators direct access to professional automation principles—lowering barriers to entry and building a community of makers while creating a pipeline of knowledgeable future customers.

Since launching, Dark Dragons Astronomy has installed systems from New York to New Mexico and many places in between. Thanks to Fusion’s powerful design and collaboration tools, they’re making the wonders of the night sky more accessible—and with no heavy lifting required.