Hear from Theo on how CloudNC is transforming machining, empowering machinists, accelerating production, and redefining the future of manufacturing.

When I first started CloudNC, I wasn’t trying to build a company – I was trying to solve a problem. Machining, the backbone of modern manufacturing, was still far too manual, slow, and error‑prone. I believed that with the right combination of software, AI, and vision, we could make accelerate machining and make machinists more productive. That idea became CloudNC, and it has shaped my life and career ever since.

From idea to reality

Back in 2015, I was a young engineer with a big ambition: to eliminate inefficiency in machining. Anyone who has spent time in a machine shop knows the frustrations – hours spent programming, trial‑and‑error setups, and the constant risk of mistakes. I wanted to change that.

The early days were scrappy. We had one lathe, a laptop, and a small,passionate team of believers. We worked long nights, often questioning whether we could really pull it off. But every breakthrough – every time our algorithms produced a toolpath that worked flawlessly – gave us the confidence to keep going.

Why automation matters

Machining is everywhere. From aerospace components to medical devices, precision parts are the foundation of modern life. Yet the process of creating them has remained complex. Skilled machinists are in short supply, and programming CNC machines are still a bottleneck.

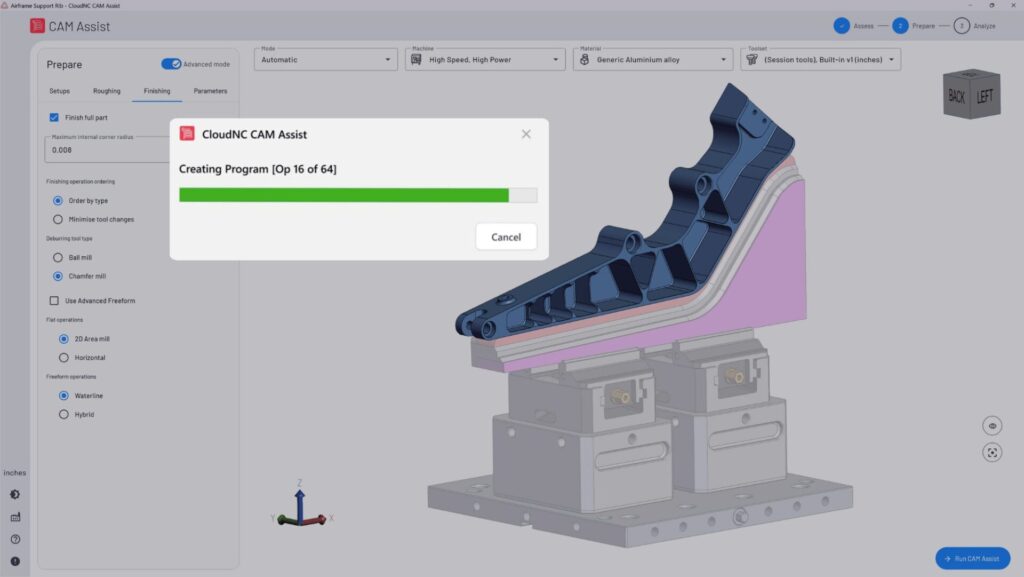

What we are doing isn’t about replacing people – it’s about empowering them. By accelerating repetitive, error‑prone tasks, engineers and machinists are free to focus on creativity, problem‑solving, and innovation. That’s the vision behind CloudNC – to make manufacturing faster, smarter, and more accessible. And since we launched our CAM Assist solution on Fusion two years ago, we now have over 1,000 machine shops using our AI to accelerate their operations across the world.

Breakthroughs and challenges

Our journey hasn’t been easy. Convincing the world that machining could be accelerated was a challenge. Many industry veterans were skeptical, and we had to prove ourselves, one customer at a time.

But the results spoke for themselves. CloudNC’s technology has been applied in industries ranging from aerospace to defense, delivering faster turnaround times, reduced costs, and improved reliability. Each success reinforced our belief that automation was not only possible – it was essential.

Lessons learned along the way

Looking back, there are a few lessons I’d share with you, the Fusion community:

- Start small, think big. CloudNC began with one machine and one idea. Don’t be afraid to start with limited resources if your vision is strong.

- Embrace setbacks. Innovation is messy. Every failed experiment is a step toward success.

- Focus on impact. Automation isn’t just about efficiency—it’s about freeing people to do their best work.

Looking ahead

Today, CloudNC is no longer just an idea. It’s a growing company with technology that’s reshaping industries, but driven by the same vision – to accelerate machining and make machinists more productive.

Fusion continues to be a partner in that mission. The combination of AI‑driven CAM from CloudNC and the power of Fusion is helping us build a future where manufacturing is faster, smarter, and more accessible than ever before.

CloudNC is proof that bold ideas can reshape the world. And Fusion has been a vital companion in that journey, providing the tools and support we needed to turn vision into reality. To all the other dreamers and innovators out there – The future of manufacturing is being built right now—and together, we’re making it happen.