This post is also available in: 日本語 (Japanese)

Driven by an innovative business model and insights from its founder’s guitar repair experience, High-end μsic set out to create an electric guitar unlike any other, leading to the launch of its own brand, Infinite. Its guitars have since earned widespread acclaim from professional musicians, including members of the J-pop group Arashi, singer LiSA’s support guitarists, and top studio musicians. Founder and CEO Satoshi Hatta credits much of the company’s success to Autodesk Fusion, which has been integral to the brand’s product development and precision manufacturing processes.

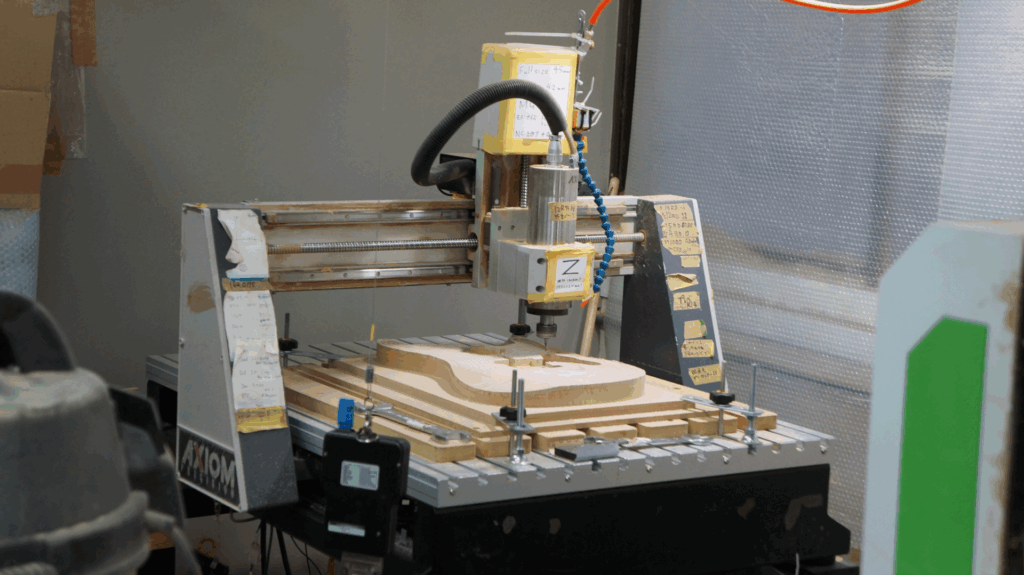

In-house manufacturing with a woodworking CNC router and Fusion

Hatta started his career as a professional guitarist and then launched a guitar repair business at the age of 24. “I taught myself guitar repair techniques,” he says. “With my experience as a guitarist, I’ve devoted myself to repairing the guitar neck, which greatly affects playability. Thanks to that, I gained the trust of professional guitarists.”

“After about seven years in business, when the repair business had stabilized, I began to think about manufacturing my original guitars,” he continues. “After repairing numerous guitars and listening to the opinions of professional guitarists, I became convinced that I could manufacture guitars that pursued a level of performance not found in existing products.”

Hatta’s decision to move from running a guitar workshop to full-scale manufacturing was driven by three key factors: the precision of CNC router technology, the supporting capabilities of an integrated CAD/CAM system, and the collaboration of his childhood friend, Shinji Okura, who could oversee design and production control.

“Satoshi and I have known each other since we were kids, and we played music together”, says Okura. “He played the guitar, and I played the drums. After graduating, I worked in computer-based graphic design, so I was proficient in using the software.”

Hatta developed a distinctive strategy when he launched his guitar manufacturing business. His goal was to build an in-house production system capable of crafting nearly every component of the instrument, excluding certain electrical circuits and metal parts. This approach allowed the company to achieve consistent, high-quality mass production with minimal variation between guitars. “It was essential to industrialize the process using CNC routers and CAD/CAM to achieve accurate and uniform woodworking, rather than relying on the manual work of craftsmen,” explains Hatta.

Kogic Logic, inspired by Japan’s unique woodworking techniques

Representative Director, High-end μsic

In Japan, electric guitar manufacturing has traditionally been divided into specialized tasks. The body and neck of the instrument are often outsourced to specialized workshops, while manufacturers focus on assembly and painting. However, “conventional electric guitars had issues with the strength of the joint between the neck and body,” notes Hatta. “In many existing products, the neck and body are only secured with bolts alone. As a result, professional guitarists often find that the neck becomes loose over extended periods of use.”

“To solve this problem, we developed a unique neck joint method called ‘Kogic Logic’ based on the techniques of Miyadaiku, a Japanese carpenter who specializes in repairing temples and shrines,” explains Hatta. “Kogic Logic is a unique method that attaches three convex parts to the neck side, carves concave grooves into the body, and increases the joint area to achieve a strong bond. It has also been registered as a utility model. To realize this ideal neck joint method, it was necessary to manufacture both the body and the neck in-house. Industrialization capable of producing these structures uniformly was also essential.”

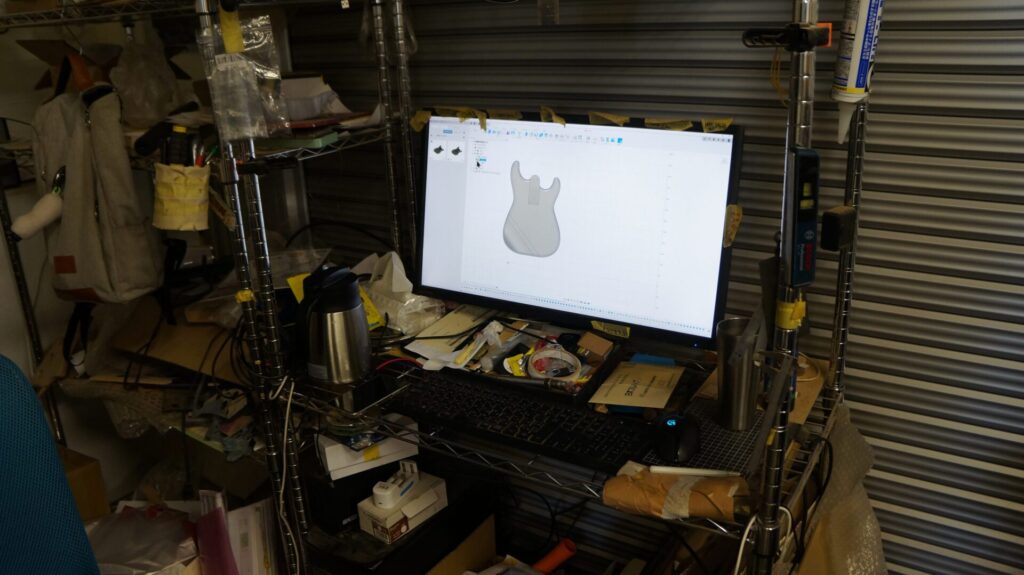

In pursuit of Hatta’s vision of Kogic Logic and industrialization, Okura took on the challenge of 3D design for the body and neck. “Although 3D design was new to me, my experience with graphic design software helped me visualize his vision for the body and neck, giving me confidence that the design was achievable,” says Okura. “However, the real challenge was controlling the CNC router.”

“Initially, we were using CAD/CAM software recommended by AXIOM, a CNC router imported from overseas,” he continues. “Unfortunately, there were compatibility issues with the data, leading to unnecessary cutting and taking 13 hours to carve out the body. This made it clear that achieving the industrialization we envisioned would be difficult.”

A giant leap in the industrialization of guitar manufacturing with Fusion

To reduce body cutting time using a CNC router, Okura considered changing the software used for CAD/CAM. “The first one I came across was Autodesk Fusion,” he explains. “After the free trial, I found that it was not only easy to use as CAD software, but also that the CAM functions included standard post processors, allowing me to operate the CNC router correctly without modifying the data. I was able to cut the body in just a few hours. For simpler models, we could complete the machining in just one hour. This led us to conclude that it would enable the industrialization Hatta was seeking.”

“With the support of Autodesk Fusion and Okura, we were able to manufacture the ideal electric guitar design and form we had in mind,” says Hatta. “The Infinite features a design supported by professional guitarists, not only in terms of the strength of the neck joint but also in the body.”

“For example, when playing high notes on an electric guitar, you press the frets near the neck, which is close to the body,” continues Hatta. “To ensure that your fingers can reach the highest string comfortably, the back of the body is designed to be as thin as possible. In conventional electric guitars, making the body too thin can compromise the joint strength between the body and neck, but with the Kogic Logic, we have ensured strength, achieving a thinness unmatched by other companies.”

Because CAD/CAM has digitalized the body manufacturing process, Infinite can even create original models and handle semi-custom orders. “Professional guitarists are particular about the type and position of pickups that affect their tones,” explains Hatta. “Many guitar manufacturers accommodate requests to change the type of pickups, but not the position. They also specify the type of wood used for the body and designs that suit each playing style. Such customization demands were previously difficult to meet due to the time-consuming nature of traditional manual processes.”

“However, with CAD/CAM, we can now flexibly customize and manufacture the body and neck by simply rearranging the created models or jigs,” he continues. “We can also provide customers with renderings of the customized models for their approval. Currently, we have a backlog of approximately one and a half years. I believe the digitalization of guitar manufacturing is a key factor in the popularity of the Infinite series among many musicians.”

Expanding next-gen guitar manufacturing with Fusion

“As part of our efforts for the future, we plan to expand our business,” says Hatta. “With Autodesk Fusion, we are training additional engineers who are proficient in CAD/CAM. We’re also considering OEM production in addition to our original products.”

“In Japan, Nagano Prefecture is famous for guitar manufacturing, but due to the aging population, many workshops are closing down,” he continues. “If this trend continues, young people who wish to pursue careers in guitar making or repair will lose opportunities to do so. We hope to expand this new-generation guitar manufacturing method using Autodesk Fusion and woodworking CNC routers to provide high-quality electric guitars at affordable prices—increasing the number of guitar enthusiasts from amateurs to professionals.”