Discover how Fusion breaks down manufacturing data silos and solves collaboration bottlenecks by connecting teams, centralizing manufacturing data, and automating workflows.

One of the most frustrating pain points manufacturing teams face is data silos – where crucial product and process information gets trapped within separate departments, software tools, or legacy systems. These barriers slow down design iterations, introduce errors, and cause unnecessary production delays. This results in lost time, increased costs, and missed opportunities for innovation. If teams can’t access or share the right data at the right time, creativity stalls, and time to market increases.

Elevate your design and manufacturing processes with Autodesk Fusion

Fusion, Autodesk’s industry cloud for manufacturing, is engineered to solve these collaboration bottlenecks. By breaking down data silos and enabling seamless connectivity across teams, tools, and business systems, Fusion transforms fragmented processes into unified workflows that accelerate innovation and boost operational efficiency.

Breaking down manufacturing data silos with connected product development

Data silos don’t just make work slower—they frustrate designers, engineers, and production managers who are constantly on the search for accurate, up-to-date information, stored in isolated systems. This can lead to slow onboarding, as new team members spend valuable time searching for files or re-creating work that already exists. Fusion provides a platform in which data flows freely and securely across all teams, regardless of discipline or location. Everyone works from a single, shared source of truth, eliminating duplication and version confusion.

The result – design and engineering processes become highly collaborative and agile. Iterations occur faster, errors are reduced, and innovation thrives because every stakeholder has the relevant data at their fingertips. Fusion also makes onboarding new talent remarkably simple – with access to design history, specifications, and documentation, projects ramp up in hours, not days.

Aligning the entire organization and ecosystem

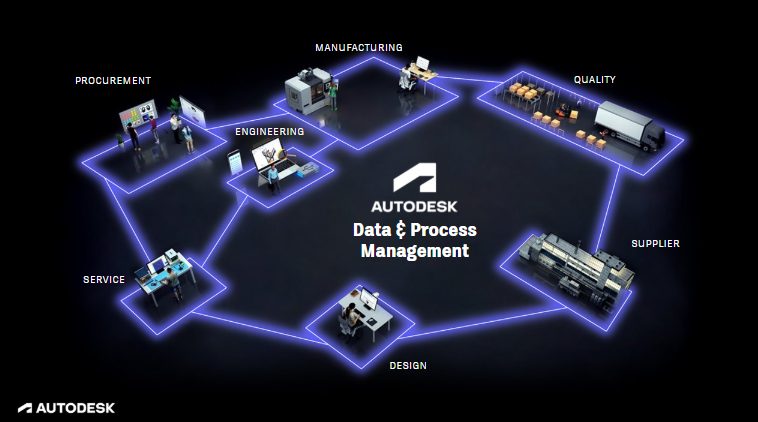

Beyond engineering, data silos commonly span manufacturing, quality assurance, procurement, logistics, sales, and marketing. Disconnected teams working from different data sets often lead to mistakes and delays. Fusion centralizes critical information such as bills of materials (BOMs), production schedules, and change orders. When teams can access live, up-to-date records, cross-departmental collaboration improves, and manual handoffs or reconciliations are eliminated.

Fusion’s integrations extend outside the organization to connect enterprise-level business systems like Product Lifecycle Management (PLM), Manufacturing Execution Systems (MES), and Enterprise Resource Planning (ERP). By linking the upstream and downstream flows of information, Fusion creates a transparent, connected ecosystem where manufacturing leaders can track projects from concept to delivery. This real-time visibility allows for proactive problem-solving and faster adaptation to customer requirements and market changes.

AI-powered automation accelerates collaboration

Silos not only separate teams—they slow down the entire design and manufacturing process. Manual data entry, repetitive status updates, and constant checking for the latest version all consume resources that should be spent on innovation. AI-powered tools in Fusion, including the Autodesk Assistant, automate routine tasks and dramatically reduce busywork. For example, users can quickly search for and act on files and part records using natural language, without worrying about complex naming conventions or property tags.

Automation doesn’t just save time—it fundamentally changes workflows. By automating approvals, updates, and data syncing, Fusion enables teams to focus on critical design, engineering, or manufacturing work.

Turning manufacturing data silos into a competitive advantage

Data silos are more than a nuisance—they are a threat to growth, innovation, and operational excellence. Fusion eliminates these silos, boosts collaboration, and accelerates workflows so manufacturers can thrive in a competitive market.

When data flows freely within organizations, teams innovate faster, deliver higher-quality products, and grow smarter with every project. Fusion transforms the pain point of data silos into a genuine competitive advantage, uniquely positioning manufacturers for success in the new digital era.

Ready to put your data to work? Explore built-in PDM and integrated PLM in Fusion, and experience the powerful collaboration it brings to every stage of product development.