Agriculture is more than just an industry in India. Contributing 16% to the GDP and supporting nearly half of the population, farming helps keep the nation running. But the industry faces deep-rooted challenges that impact farmer incomes and food security.

In India, approximately 30% of fruits and vegetables are lost post-harvest due to limited access to cold chain infrastructure. Farmers’ livelihoods are hindered by market fluctuations and the inability to wait for better prices. Ecozen has set out to solve these challenges in a sustainable way.

“Our vision has been to enable climate-smart agriculture,” says Devesh Yadav, Assistant Vice President of Technology and Design, Ecozen. “We started with a mission to empower farmers using sustainable tech solutions that could make their lives better. From day one, we have been focused on solving real problems like irrigation and cold storage with a focus on clean energy.”

Delivering sustainable solutions directly to farmers

Ecozen currently has two flagship products that bring renewable energy to everyday farming. Ecofrost is a container-sized, solar-powered refrigerator, allowing farmers to store perishable products, such as fruits and vegetables, for longer periods. These containers are delivered locally and on site to extend the cold chain infrastructure for increased accessibility. Ecozen has also developed Ecotron, which uses solar energy to drive submersible pumps for irrigation.

The company’s scale is already remarkable. Ecozen’s technologies have impacted more than 1.2 million lives, avoided 2 million metric tons of greenhouse gas emissions, reduced perishable waste by more than 19,000 metric tons, and saved 315 million liters of diesel. Their systems have also generated 945 million kilowatt-hours of clean energy.

Farmers are seeing the difference firsthand. Ecofrost allows them to keep fruits and vegetables fresh after harvest. With more time to sell, they can wait for better market prices. Ecotron has enabled irrigation of more than 600,000 acres, helping farmers grow crops even in the off-season.

“We have seen an incredible impact on the ground,” Yadav says. “Farmers are increasing productivity and earnings and significantly reducing their post-harvest losses.”

Making new inroads with Autodesk Fusion

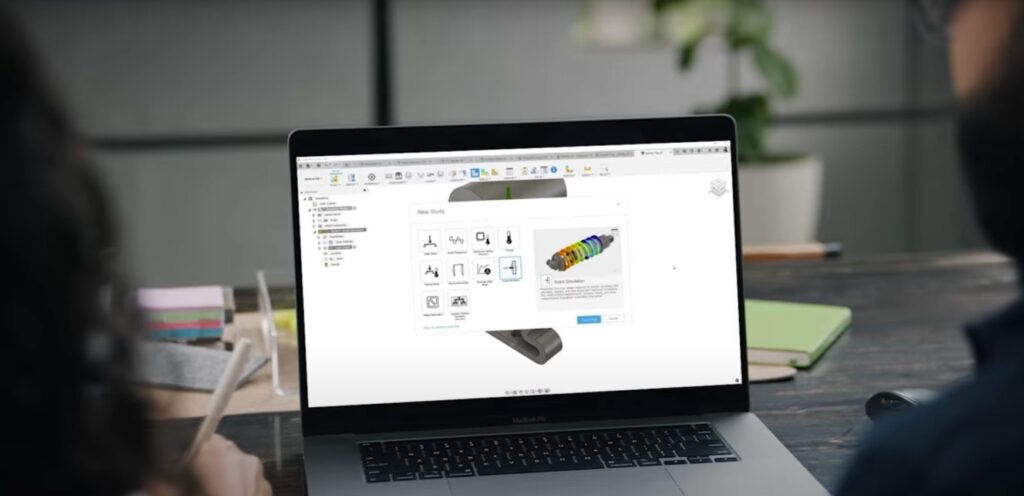

Ecozen’s forward-thinking innovation also extends to their design and manufacturing approaches. One of these is a switch to Autodesk Fusion. The company now relies on Fusion to accelerate design, improve collaboration, and cut costs.

“Initially, our workflows were siloed,” Yadav says. “For example, a CAD person would design first and then perform CAE simulations in another software with many iterations. In contrast, Fusion integrates CAD and simulation in one software, significantly simplifying the CAD engineer’s workflow and allowing us to achieve about 80% of the final design even before submitting to CAE.”

Ease of use with Fusion has also accelerated adoption across the team. “Fusion has a very intuitive and modern user interface, which makes it easy to learn, especially for engineers familiar with CAD tools,” Yadav says. “The learning curve is relatively short, and our team was able to reach proficiency within just one to two months of hands-on use. This quick ramp-up helped us realize value from the platform.”

“The design and simulation workflows are integrated in Fusion, resulting in faster turnaround times and improved accuracy. A major advantage we observed was the significant cost savings. With Fusion, we were able to save up to 30% on our calculated investment.”

—Devesh Yadav, Assistant Vice President of Technology and Design, Ecozen

Scaling smarter with Fusion Manage

As Ecozen expands, so does the complexity of its product line and operations. The company decided to make the move to Fusion Manage to scale with its growth. Maintaining BOM and product data has now become much simpler and more reliable. Errors are now reduced, and the handoff between teams is now streamlined and traceable.

“Early on, implementing Fusion Manage as our PLM solution was a smooth and structured process,” Yadav says. “We were able to roll it out and onboard our teams within just two quarters.”

Fusion Manage is helping them truly transform how they oversee product lifecycle management. “With Fusion Manage, we were able to bring all stakeholders right from ideation to product development and even production onto a single platform,” Yadav says. “This helped improve visibility and accountability across departments.”

Looking to the future

Ecozen continues to accelerate as it continually refines current products and innovates new solutions. For Yadav, it comes down to a holistic approach and the end results.

“Honestly, it’s not just about better tools,” he says. “It’s about better outcomes for our teams, for our farmers, and for the planet.”