This post is also available in: 日本語 (Japanese)

Oasa Electronics Co., Ltd. has transformed itself from a contract manufacturer to a development-driven enterprise, guided by its corporate philosophy: “Advance in all things and challenge society with the highest quality.” In partnership with GK Design Research Institute Hiroshima, Oasa Electronics developed the Egretta audio brand—an Italian-inspired name meaning “egret”—with a strong commitment to Japanese manufacturing.

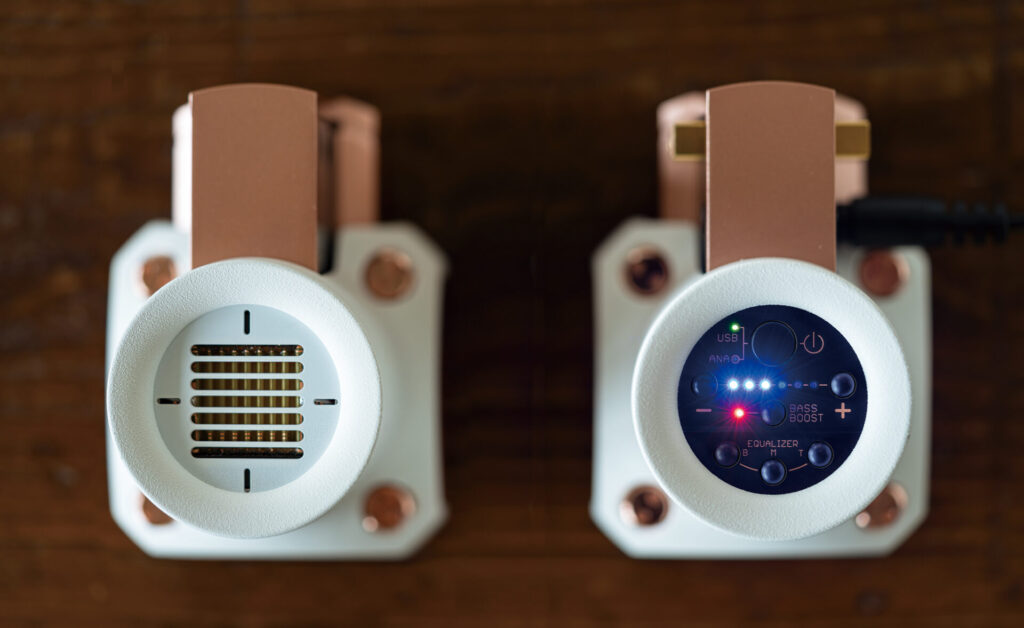

Egretta products blend refined audio performance with design that complements any interior, earning high praise from industry magazines. The latest model, produced in Hiroshima Prefecture, was co-developed using Autodesk Fusion’s cloud-based solution.

From OEM expertise to original product development

Takeshi Yamamoto, director of Oasa Electronics’ Development Technology Office, explains the origins of Egretta: “Our long experience in OEM audio manufacturing equipped us with deep development know-how. In 2011, we launched Egretta as our original brand, focusing on omnidirectional speaker systems—uncommon at that time—and products that match sophisticated interiors. Since the first model, GK Design Research Institute Hiroshima has supported us in product strategy, design, and marketing.”

Daisuke Endo from GK Design, who led the design of the latest Egretta model, recalls: “Even before I joined the Egretta team, there were colleagues who had driven brand building and marketing, forging the iconic tower-style speaker and its unique identity. The name ‘Egretta,’ evoking an egret, was chosen to mirror the elegant silhouette of our white tower design.”

Evolving design practices with Autodesk Fusion

“When we first started the Egretta brand, sketches and 2D drawing tools were used to exchange design ideas,” says Yamamoto. “After Autodesk Fusion’s initial release in 2015, we started adopting it—even personally—to visualize concepts in 3D.”

“In addition to Egretta-related designs, we have been using Autodesk Fusion within GK Design,” adds Endo. “Fusion is so capable of converting 3D data that it has helped me open difficult files many times. Immediately after loading the file data, it’s included in our designs, so we now rely on Fusion for this part of our workflow.”

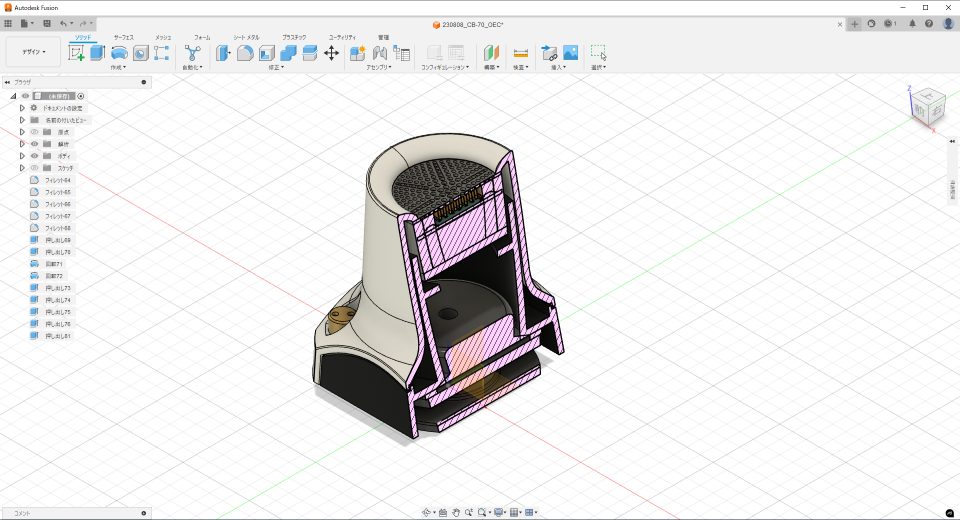

“We began trialing Fusion around its major update in 2019, and by 2020, we had fully integrated its 3D modeling, CAM, and prototyping capabilities,” continues Yamamoto. “Fusion’s CAM functions allow seamless operation with our in-house NC machining, and we also it for 3D printing. Egretta has a compact product shape, so in order to achieve high sound quality in a small housing, we thoroughly verify the shape of the product and the placement of the parts to be used through Fusion’s cross-sectional analysis feature.”

Accelerating collaboration via cloud-based design sharing

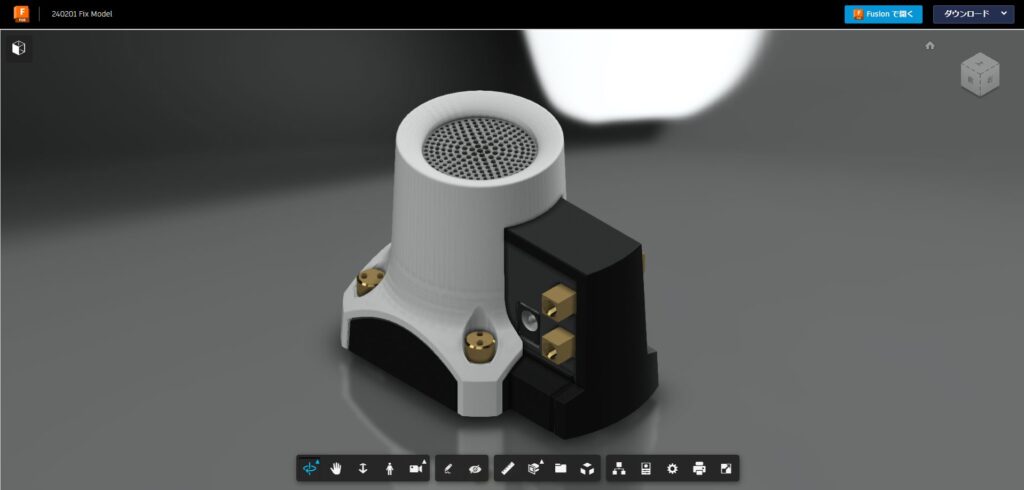

Joint development of the new Egretta speaker, which launched in spring 2024, leveraged Autodesk Fusion’s cloud services for improving collaboration, both internally and externally. “Previously, sharing and confirming design details with partners who couldn’t access our data required lengthy rendering and documentation—more than half a day. Now, uploading designs to the cloud takes less than an hour, improving efficiency. Real-time 3D data sharing enhances communication accuracy and accelerates project timelines. Freed design resources can instead focus on refining 3D data for higher product quality, so we can take the design to the next level in the same amount of time.”

“Fusion’s cloud platform enabled direct data exchange with GK Design, which increased development speed,” Yamamoto adds. “Even partners without Fusion access can review models in the web viewer, making it easier than ever to communicate. CAM integration also leads to time savings. Previously, conversion from 3D to 2D and machine operation required multiple steps. Now, the process is shortened by about 70%, speeding prototype feedback.”

Building outstanding made-in-Japan products with Fusion

Reflecting on their latest achievement, Yamamoto points out that, “While the market is filled with small, affordable speakers, our new Egretta model uses a tweeter developed in-house and proprietary technologies such as low-frequency enhancement, developed entirely in Japan. We’re proud to use Fusion to achieve excellent sound in a compact design and coordinate closely with GK Design.”

“Fusion’s high-resolution renderings can be used as product images in catalogs and support promotion and branding at early or intermediate stages—even before actual product photography is available,” Endo adds. “From development to design to manufacturing, we believe that if we can unify data in all product processes and use analysis from a design perspective, we will be able to use our time in completely different ways, contributing to better product development.”