This post is also available in: 日本語 (Japanese)

ISUZU Central Research Institute is advancing the use of generative design in Autodesk Fusion to optimize diesel engine gear structures, aiming to reduce gear rattle noise while improving fuel efficiency.

It’s anticipated that the world’s population will reach 9.7 billion by 2050, with two-thirds living in urban areas. As cities expand, maintaining a comfortable urban environment will depend on safe, secure, and sustainable urban development—driven by environmental stewardship, infrastructure enhancements, and stricter regulations.

In response to this impending future, ISUZU Central Research Laboratory conducts advanced research on commercial vehicles and diesel engine technologies, laying the groundwork for future ISUZU Motors products. In December 2024, the laboratory published a paper titled “Gear Structure Optimization of Diesel Engines Using Generative Design,” introducing a revolutionary solution to the gear rattle noise (the characteristic “teeth clattering” sound that occurs during torque fluctuations and reversal) generated by the engine of the “ELF” light truck. Their approach involves developing a new, significantly lighter gear.

Meeting expanding requirements with design automation

“Automobiles have countless components, and now there are more factors to consider, such as using recycled materials to achieve a circular economy,” explains Seiya Yamagishi, Chief Researcher, ISUZU Central Research Laboratory. “Responding to various social demands and regulations requires tools that enable extensive exploration—we strive to keep pace through design automation.”

In the Elf engine, a series of gears transmit power from the crankshaft to the camshaft. Among these is a scissor gear—two overlapping gears connected via springs—which reduces rattle noise by sandwiching the mating gear. However, this solution also increases the number of parts and assembly labor, driving up manufacturing costs (due to the increased number of parts and installation time) and causing challenges such as greater friction, declining fuel efficiency, and wear.

Seeking to eliminate these trade-offs and avoid reduced fuel efficiency, the team used simulations and found that reducing the gear’s weight was a potential solution. “However, to match the effectiveness of the scissor gear, we needed to achieve a 30% to 40% weight reduction,” Yamagishi notes. “We had already tried lightweighting gears by drilling holes, so we worried there wasn’t much material left to remove.”

Leveraging generative design in Autodesk Fusion

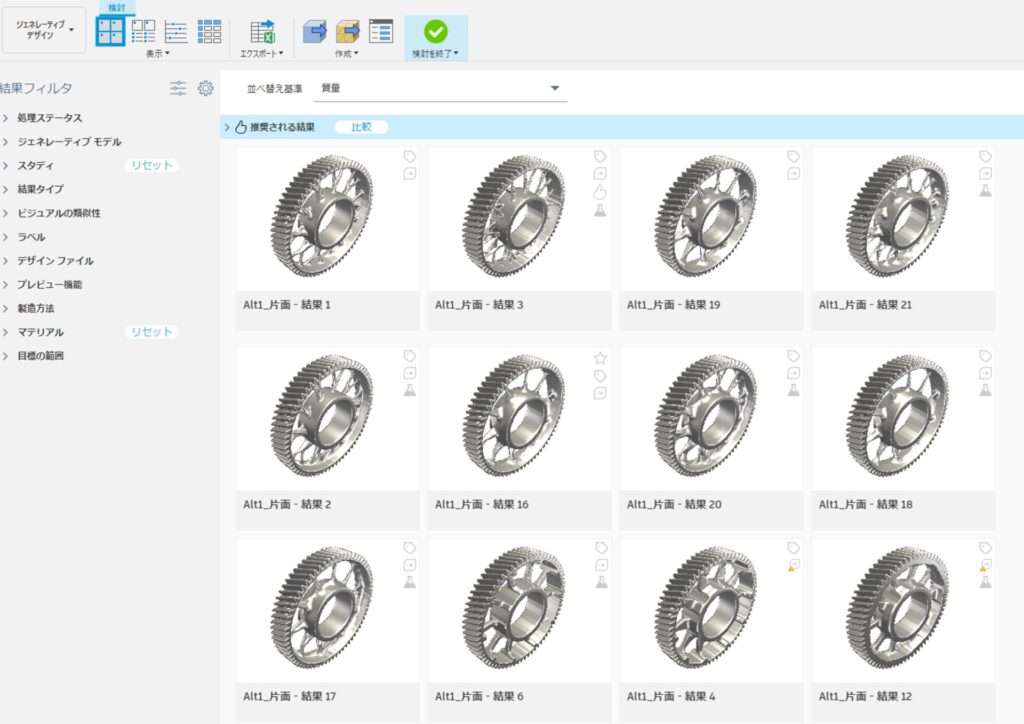

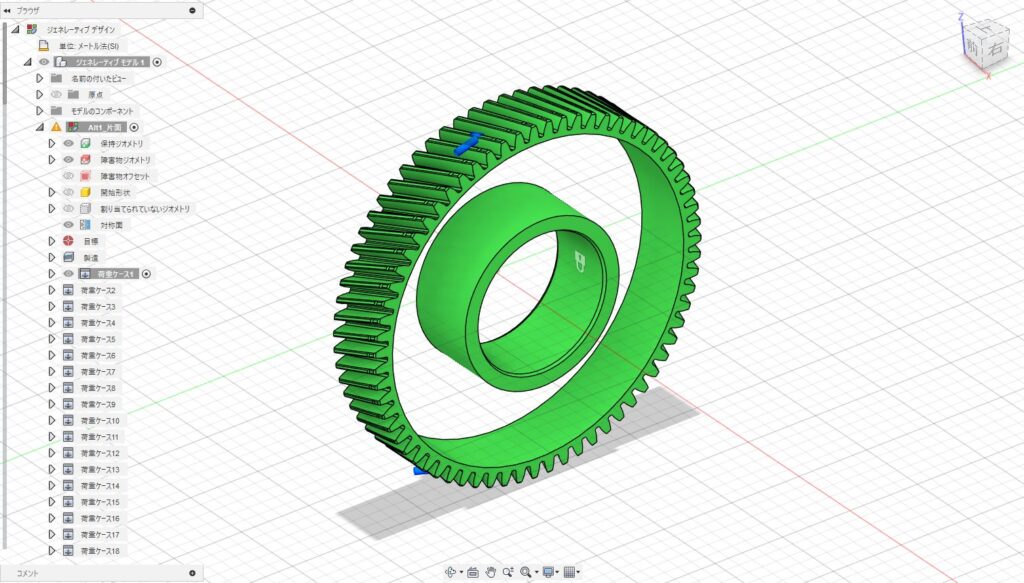

Generative design in Autodesk Fusion uses AI and cloud computing to rapidly generate diverse design ideas based on key parameters—materials, manufacturing methods, and performance needs—offering creative solutions that human designers might never imagine. “There weren’t existing examples of applying generative design to gears, but after consulting Autodesk, we learned that it was feasible by specifying surface loads,” Yamagishi recalls. After two months of design refinement, the selected prototype achieved an outstanding 43% reduction in weight.”

“We were able to create shapes suitable for machining. Since the gear isn’t visible from outside, aesthetics weren’t a priority, which allowed us to accelerate prototyping,” he continues. “By March 2022, engine firing clearance hadn’t been granted yet, so initial evaluation relied on motoring tests without fuel combustion.

Results and next steps

Once post-test verification confirmed no issues, the design underwent further review and moved into actual operation in November of the same year. “Replacing two gears with prototypes yielded the same level of noise reduction as scissor gears, plus a 0.5% improvement in fuel consumption,” Yamagishi reports.

“We conducted an accelerated study, but we were able to proceed in a very short time from the examination to the actual creation of a shape. Considering manufacturability at the prototype stage was also a major advantage,” says Yamagishi.

Mr. Yamagishi is preparing for mass production in the future. “Commercial vehicles are used for quite a long time, and they require large-scale tests to keep the engine running, so we would like to include them in such endurance tests. Gears that are only on the surface are easy to consider, but we are also starting to consider more complex shapes.”

A new mindset for the next generation of designers

These new technologies are also sparking interest among younger designers. Reflecting on his own experience, Yamagishi notes, “When I was at university and later in the lab, the idea was that it was enough to master one field deeply. You could build a career relying solely on specialized expertise.”

“Now, with AI tools—especially generative AI like ChatGPT—information is instantly accessible. The barrier to acquiring knowledge has dropped dramatically. But because of that, it’s no longer enough to focus on just one area. Young designers today need to build a broader base of knowledge. Generative design, in particular, requires a very different mindset—it’s not about drawing traditional blueprints, but more about thinking in terms of simulation. The most important step is to start experimenting and learning through hands-on use.”