Engines roar as cars race 12.42 miles up a small, winding road to Pikes Peak, climbing nearly 5,000 vertical feet and finishing in the clouds at over 14,000 feet. Supplemental oxygen is pumped into the driver’s helmet. The extreme physicality of reaching the summit is undeniable, gripping through 156 turns with no power steering and G-forces like a fighter jet. Not to mention unpredictable weather and sheer drops without guardrails, leaving zero margin of error.

And, in 12 minutes, give or take, it’s all over.

That’s the experience of Pikes Peak International Hill Climb, one of the most dangerous and demanding motorsports events in the world. No do-overs. Just one run.

Each June, racers from around the world come together to experience this historic race that first started in 1916. Every team’s passion and intensity are palpable after a year of designing and manufacturing the optimum car to conquer the summit and win the race. No one knows this better than Robin Shute, founder of Shute Dynamics and awarded the prestigious title of “King of the Mountain” with a record four wins.

A lifelong automotive passion

You could say cars and racing are in Shute’s DNA. His father helped design the iconic Lotus Elise and bring it to the U.S. market. Growing up, Shute was already close to the industry and even began learning CAD and designing electric hill climb cars when he was 16. He moved to the United States and eventually worked at Tesla as an engineer. During that time, his interest in motorsports piqued again.

Shute began racing as a hobby with his coworkers. He also discovered Autodesk Fusion, which became essential to his design process. His first competitive car at Pikes Peak, nicknamed “The Wolf,” was originally an Italian chassis that he and his team heavily modified. Despite the car’s potential, their debut year in 2018 was plagued by engine issues and bad weather, preventing them from showing their true capability. But it laid the groundwork—and determination—for what came next.

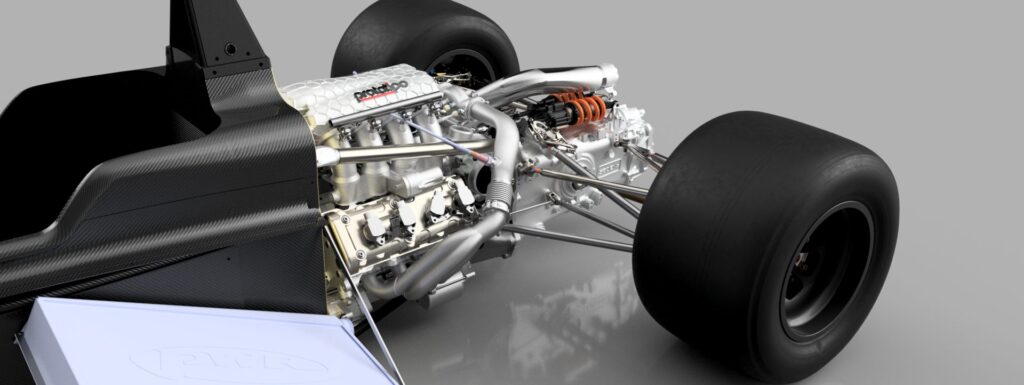

With lessons learned and a growing understanding of the mountain and designs for the car, Shute returned stronger in 2019 and claimed his first win. Since then, he’s proved that victory was more than, as he calls it, a “flash in the pan.” With Yokohama now as a partner and sponsor, Shute is designing a brand-new car called “Sendycar V1.” It’s his first car designed and manufactured from scratch, and he plans to race it at Pikes Peak in 2026.

“I’ve had four overall wins with The Wolf, but I really want to go and set the overall record with the fastest car ever up the mountain with Sendycar V1,” Shute says. “This journey started in earnest about two years ago, and I was able to ramp up really quickly with Fusion’s ease of use. It allows you to design professional-grade parts, whether it’s with generative design or CAE. I’ve done the entire function of an OEM to design a whole car by myself using software that costs only hundreds of dollars.”

Creating the ultimate, aerodynamic Sendycar V1

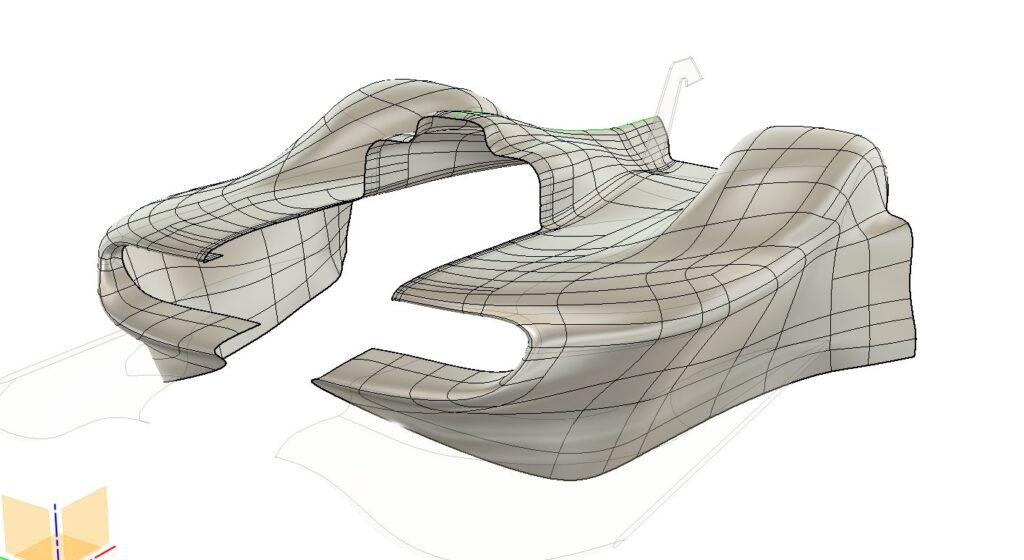

One of Shutes’s greatest advantages for Sendycar V1 lies in aerodynamic innovation, which is made possible in a single platform with Fusion. Much of his focus on aerodynamics is modeled and developed largely by Fusion’s T-Spline modeling and simulation tools.

“T-Splines in Fusion are really important,” he says. “You can create models quickly, output them for CFD testing, and iterate in less than an hour. That’s unheard of in the industry.”

“I designed the final body surfaces in T-Splines,” he continues. “It’s been huge to have that capability. Not many CAD programs can get close to it. It’s especially impressive as someone from the OEM world who knows full-time employees are doing surfaces all the time on just portions of the car, not a whole car, and one person doing it. I probably have hundreds of evolutions of the car in Fusion.”

This workflow and flexibility helped Shute design surfaces so aerodynamically efficient that, as he puts it, “it could drive upside down in a tunnel at 80 mph.”

Generative design infuses new potential

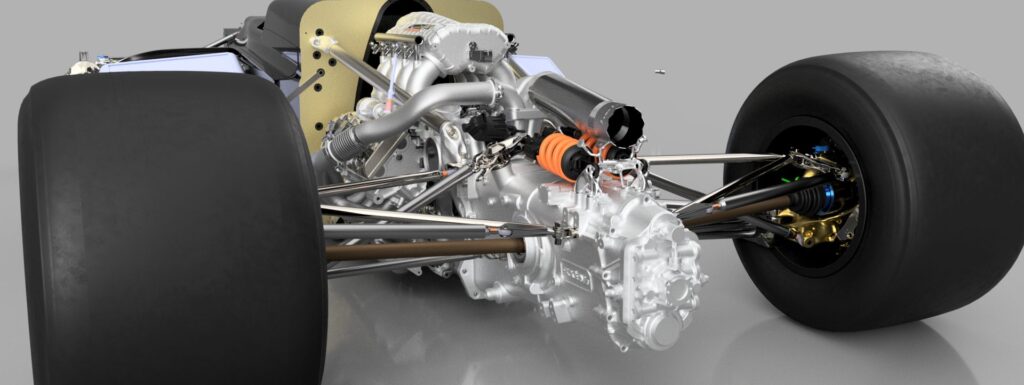

Shute also attributes much of his design success—from suspension to bell housing—to the use of AI-powered generative design in Fusion. Lightweighting, strength, and stiffness are paramount for his priorities. According to Shute, learning and using generative design has evolved his design philosophy completely when it comes to conceptualizing and designing certain components.

“Generative design is something I love because it ensures parts are fully optimized, lightweight, and strong enough,” he says. “There’s no room for extras in these car designs, and I can make things very multi-functional to combine different part functions into one part, such as the rear shock absorber mount. I have added the bodywork mount, the exhaust mount, and the heave spring mount all to that one part, which weighs just 100g.”

“Everything must be optimized because the competition is stiff,” he continues. “There’s no room for being ‘good enough’ because it must be the best to compete. There are OEMs that put tens of millions of dollars into their cars. You really need to lean into modern technology, and that’s where generative design and all the professional-grade capabilities available with Fusion help us succeed.

“Complicated parts are hard to engineer, and they can take years to develop. But using generative design in Fusion, you can put multiple functions into one part, iterate, prototype, and it’s just a matter of weeks for a final product.”

—Robin Shute, Founder, Shute Dynamics

Race ready

Each day, Shute continues to pursue not only Sendycar V1 but also consulting for other teams and developing new motorsport innovations globally. For the 2025 Pike’s Peak race, he raced a 1969 Camaro from DuSold Designs. They also used Fusion for the design, and Shute helped contribute some of the aerodynamic work as well.

His ultimate test will be preparing for that ride up to the summit in his own new creation in 2026 with Sendycar V1.

“With Fusion as the development platform, I can take Sendycar V1 to the next level of performance,” Shute says. “I can’t wait to see what we do on the mountain in 2026.”

Want to learn more about Shute’s process? Check out this episode of the Shop Talk podcast: