When the world shut down in the early days of the COVID-19 pandemic, a painful reality emerged. Patients were isolated in hospitals, and many families were left with the haunting memory of never saying goodbye to loved ones. Seeing these experiences deeply impacted entrepreneur Janis Münch. It sparked an idea to help immunocompromised patients safely reunite with loved ones, ultimately leading to him founding Sphaira.

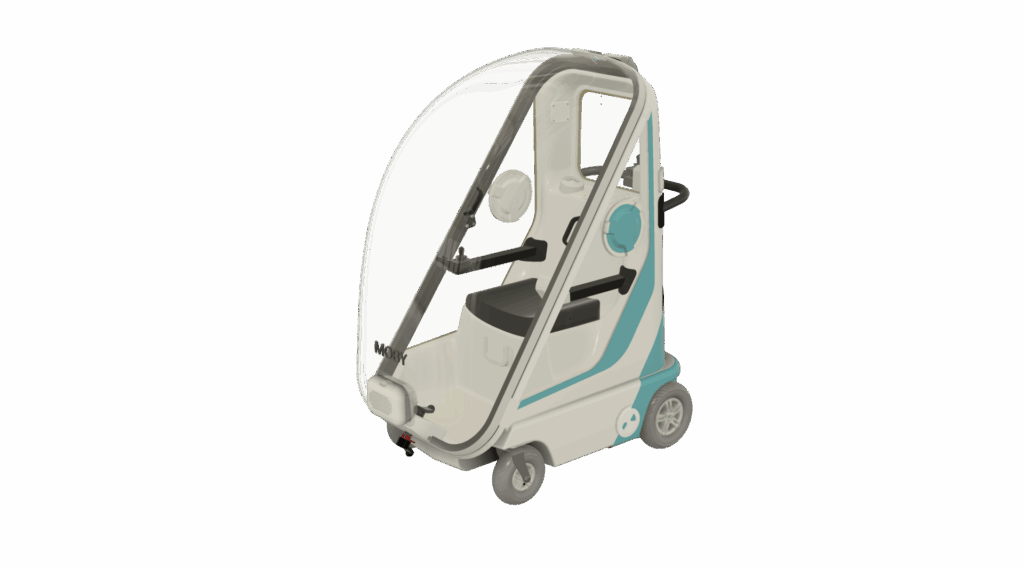

What began as a vision of a wheelchair encased in a clear, protective bubble evolved into something even more innovative. MOBY P1 was developed as a self-contained, protective vehicle. Designed specifically for isolation patients, such as those with a weakened immune system or with infectious diseases, MOBY P1 provides a clean, secure environment that allows patients to leave the confines of isolation wards without potentially endangering their health or the health of others.

MOBY P1 is certified as a Class I medical device and meets ISO cleanroom Class 2 standards, which is extraordinary for a mobile unit. To put this in perspective, standard hospital isolation wards typically operate at Class 7, and even high-tech operating rooms usually only reach Class 5. MOBY P1 is effectively a rolling cleanroom that protects patients, their families, and medical staff from exposure while enabling close contact and restoring patient mobility.

MOBY P1 is already being used at Germany’s largest hospital, Charité University Hospital Berlin, particularly in the pediatric oncology department, where children in long-term isolation can now safely see their families, feel sunlight, and experience a sense of freedom.

“One little girl hadn’t seen her siblings for four weeks after her bone marrow transplant,” Münch recalls. “Using MOBY P1, she was finally able to reunite with them. That’s something you don’t forget.”

Switching to Autodesk Fusion

To bring MOBY P1 to life, the Sphaira team made a pivotal software shift from SolidWorks to Autodesk Fusion. For a fast-moving startup, the decision came down to cost, flexibility, and the ability to collaborate remotely.

“As a startup, Solidworks limited our flexibility,” Münch says. “The licenses were expensive and tied to specific machines. We had to physically ship laptops to freelance engineers just so they could work. It felt we were in an older era.”

Fusion offered the freedom the team needed. Working in the cloud, engineers could collaborate from anywhere, allowing the design team to scale and adapt quickly during a time of intense development.

Fusion’s design environment also aligned more closely with the team’s agile development process. “Our engineers now work more fluidly,” Münch says. “It’s easier to prototype, iterate, and work across time zones and roles.”

Whether traveling or collaborating remotely, Aleksandr Kozlenok, head of hardware at Sphaira, can even open the full product assembly on his iPad, take measurements, create sections, and collaborate with suppliers in real-time.

“Working in the cloud with Fusion is so beneficial,” Kozlenok says. “I can be traveling, on a train, or on-site with a supplier and still access and review assemblies. I don’t even need my computer. I can just bring my iPad and work anywhere.”

Taking advantage of Fusion features

Before joining Sphaira, Kozlenok’s background was rooted in automotive and robotics, working primarily with Siemens NX, SolidWorks, and CATIA. But since transitioning to Fusion, his team has discovered powerful advantages, especially when working with complex surface designs and refining MOBY P1’s unique exterior.

“The interface felt natural right away,” Kozlenok says. “We were impressed that Fusion’s standard license included features that normally require advanced bundles elsewhere. For example, being able to directly delete faces or features from imported STEP files saved us from having to redesign entire parts from scratch.”

Elevate your design and manufacturing processes with Autodesk Fusion

With the next version of MOBY P1 underway, they are leaning into Fusion’s surfacing tools even further and redeveloping some complex exterior components from scratch.

“We really like the features for inspecting the continuity of parts,” Kozlenok says. “Features like Zebra Analysis are also very helpful for checking the quality of the shape. Every ventilation system and ergonomics component was 3D printed and tested to deliver the optimal user experience while ensuring that components can be easily assembled together.”

“Working on MOBY P1 is different from anything I’ve done in the automotive industry. Typically, you just release a car, and then that’s it. Working at Sphaira we can see firsthand how our designs are helping patients, especially children, and hear directly from medical staff how much they appreciate its thoughtful design. That kind of impact, where you see your work improving lives in real time, is incredibly motivating.”

—Aleksandr Kozlenok, Head of Hardware, Sphaira

Lifecycle management with the Fusion Manage Extension

As a medical device company, traceability and strict version control are paramount. With the Fusion Manage Extension, Sphaira’s team established a streamlined process for Bill of Materials (BOM) creation and approval and customized it to meet internal standards while maintaining simplicity.

“With the Manage Extension, the ability to assign peer reviewers and approvers for each component is very helpful because that level of traceability is essential for patient safety,” says Kozlenok. “You can trace an issue back to the change order and see who approved it. It brings a level of accountability and transparency that’s vital in our field.”

The team has developed a system with the Fusion Manage Extension where BOMs are parsed via internal scripts, enriching the data with supplier details and automatically publishing them to Atlassian Confluence for documentation. Each part version is accompanied by STEP files and technical drawings, ensuring everyone, including engineers, suppliers, and more, stays on the same page.

Moving forward with new opportunities

Sphaira’s journey continues to gain momentum. The company is actively working toward FDA approval in the United States. Hospitals such as Stanford Children’s have already expressed strong interest in MOBY P1, with ongoing discussions for partnerships and pilot programs. Sphaira is also actively engaging with major institutions like UCSF and the Mayo Clinic.

And MOBY P1 is just the beginning. The team is also developing an autonomous Shuttle Pod—a futuristic, driverless vehicle designed to move patients around hospital corridors or even airports.

As global populations age and care staff shortages become more pressing, mobility aids like the Shuttle Pod are poised to meet rising demands for assisted transport in healthcare and beyond. Built in collaboration with an ex-Tesla designer and supported by major investors from the German automotive industry, the Shuttle Pod represents the next generation of what Sphaira calls “Intramobility.”

“We believe Intramobility—the autonomous movement of people indoors and on-site—is the next frontier of mobility,” Münch says. “It’s not just about transport. It’s about restoring dignity, connection, and freedom to those who need it most. With tools like Fusion and the ingenuity of our team, we’re redefining how people move through the spaces that matter most.”