Learn why unified ECAD MCAD design is the logical choice for modern engineering, and how Autodesk Fusion delivers on that vision.

The nature of product development has changed in the past decade as reliance on electronics has increased. Electronics used to be considered standalone systems within a larger product. However, today’s products require electronics to be inseparable from the form, function, and performance of a system. In this context, the traditional separation of electrical and mechanical design disciplines is no longer sustainable. This convergence of responsibilities requires tools and workflows that support a cohesive, concurrent design methodology. Learn how Autodesk Fusion is a powerful ECAD MCAD tool for integrating electronics into the standard product design workflow.

The case for ECAD MCAD integration in modern electronics design

The technical rationale for ECAD MCAD integration begins with the design verification process.

Engineers face inherent limitations in evaluating physical interactions when ECAD and MCAD data are siloed. Early misalignments in component clearance, connector alignment, heat sink integration, and EMI shielding lead to costly prototype revisions. Conventional workflows using STEP or IDF files for collaboration introduce latency into the design process. They often fail to capture the full intent of either design domain. For example, mechanical constraints that affect board routing can be overlooked until late in the process, and ECAD updates to layout or part placement may not propagate cleanly back to the mechanical side without manual intervention.

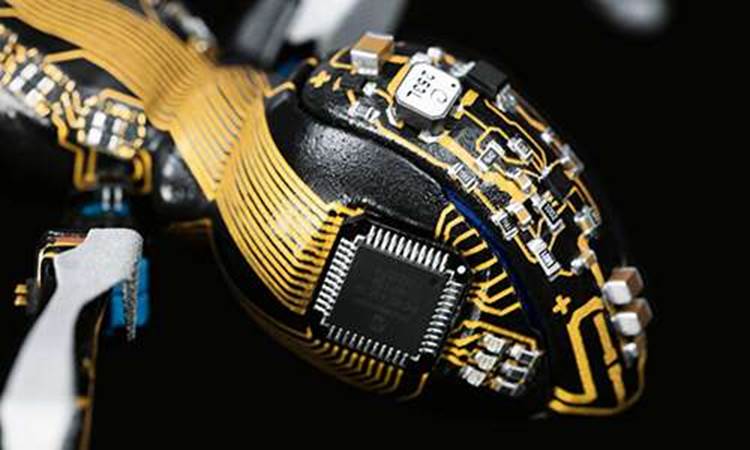

The growth of more compact, multi-functional designs (e.g., molded interconnect devices (MIDs) and wearable electronics) also necessitates accurate 3D modeling of electronic systems. 2D representations are insufficient for understanding spatial relationships and predicting performance in the final physical form. This is particularly true when working with complex stackups, high-speed designs, or devices operating in thermally or mechanically constrained environments.

Integrated platforms unlock true co-design. The boundaries between electrical and mechanical engineering are managed through shared datasets and synchronized updates. This leads to faster iteration cycles and improved product quality. These benefits directly translate into faster time-to-market, reduced costs, and a more agile response to component availability and specification changes.

Fusion as a solution for ECAD MCAD integration

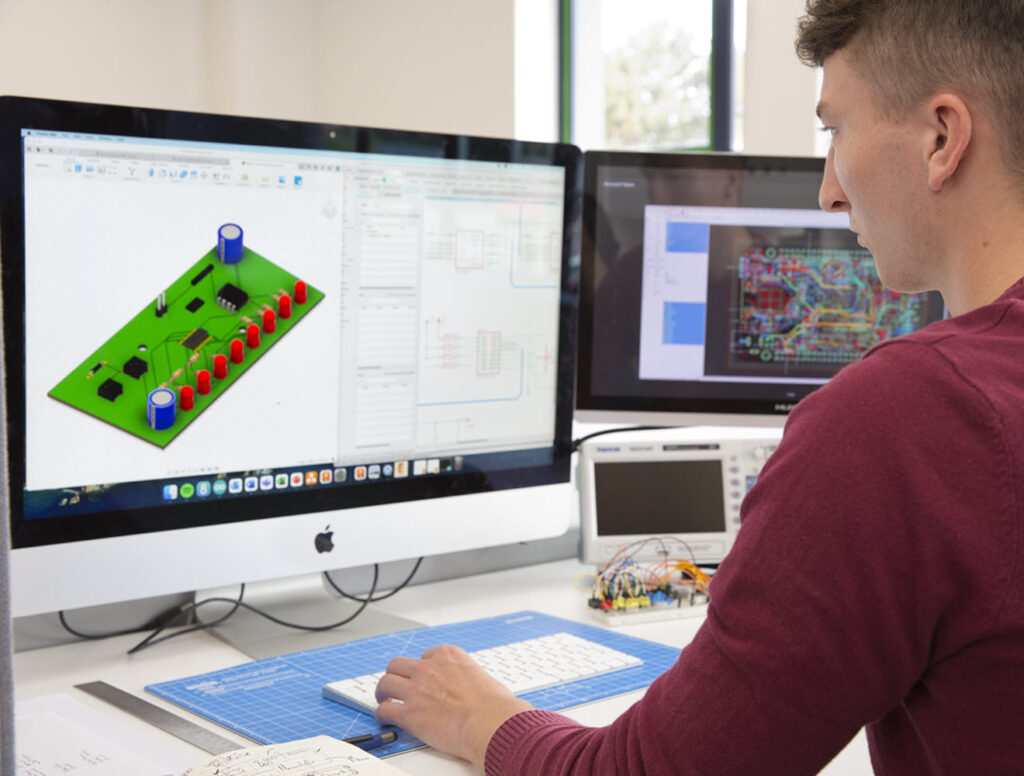

Autodesk Fusion addresses these integration challenges head-on by offering a single, cloud-based platform that merges schematic design, PCB layout, mechanical modeling, simulation, and manufacturing preparation within one environment. Engineers working on electrical and mechanical aspects can interact with the same project data in real-time. This can be done from any location and on any device.

PCB editor

Fusion’s 3D PCB editor is at the heart of its integrated approach. Unlike tools that treat mechanical interaction as an afterthought, Fusion’s PCB editor allows engineers to define board geometry using actual enclosure models. This ensures precise integration between the electrical and mechanical aspects of the design. The mechanical profile is projected directly into the PCB workspace to guarantee exact alignment between the board and housing. Changes in one domain, like a shifted mounting hole or a revised connector location, generate alerts across the design team. This prompts immediate review and synchronization.

Fusion also allows engineers to specify material properties within the PCB stackup for accurate simulation of thermal and mechanical performance. With support for true 3D copper modeling and material characterization, engineers can run simulations that reflect the actual physical behavior of the board in its final form.

Schematic capture and circuit simulation

In addition, the platform’s schematic capture and circuit simulation tools are tightly coupled with the layout environment and feature centrally managed libraries. This capability reduces redundancy and maintains consistency across projects. The MCAD side of the platform supports comprehensive part modeling, interference checking, and motion simulation features that make it easier to validate fit and function in early design stages.

Built-in PCB fabrication tools

Fusion also facilitates manufacturing handoff with built-in tools for PCB fabrication output—including Gerber generation, drill files, and assembly documentation. Combined with CAM tools for mechanical part machining, the entire workflow from concept to production exists within a single platform. No additional licenses, plugins, or export routines are needed, which dramatically reduces cost and complexity.

Unifying design

As engineers face tighter timelines, smaller form factors, and more interconnected products, the need for unified ECAD MCAD tools becomes more and more obvious. Autodesk Fusion delivers on this need with a fully integrated environment that removes barriers between design domains, reduces design cycle times, and enhances product quality. Whether you’re designing compact wearables or industrial control systems, Fusion enables you to engineer, simulate, and build with confidence on a single, cohesive platform.