AIRPLAN

Airplan: The power of the cloud in life sciences engineering

A commitment to productivity with BIM powered by Autodesk

The Cloud and BIM in Life-Science Industry Projects

Airplan, a company specializing in design, engineering, and turnkey project installation solutions, has increased its productivity by 30% thanks to the cloud and global implementation of BIM. This approach is ideal for cleanroom projects, allowing the creation of a model repository that can be reused to reduce rework. To achieve this, Airplan has integrated various Autodesk solutions, including Revit for modeling, Docs for document management, and BIM Collaborate Pro for cloud-based collaboration with both internal and external stakeholders, leading to an 80% client renewal rate.

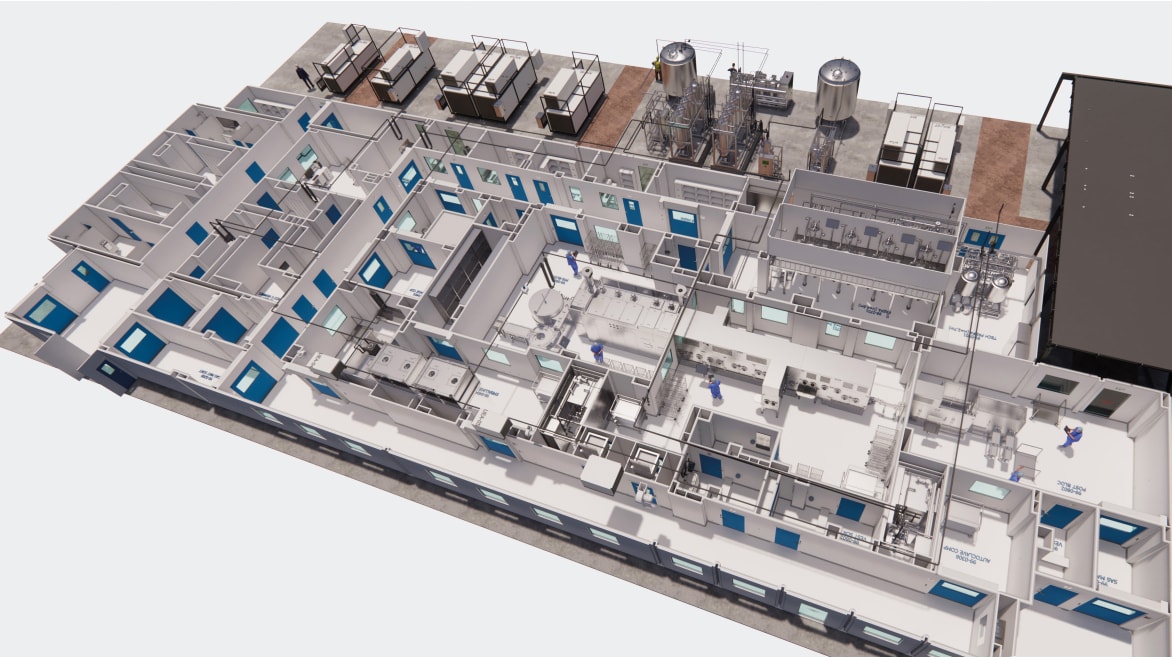

Cleanroom. Image courtesy of Airplan

Comprehensive projects

Founded in 1968 in Barcelona, Airplan initially focused on air treatment for the textile industry. Over time, it evolved to specialize in turnkey solutions for the design, engineering, consulting, and installation of cleanrooms and process lines within the life sciences sector. This specialization has enabled Airplan to expand nationally and internationally, completing over 3,000 projects in 48 countries, with a team of 120 collaborators and an 80% customer retention rate.

Airplan’s expertise is divided into three main areas: providing comprehensive process solutions, developing cleanroom infrastructure, and manufacturing process lines for various products, including creating sterile spaces for pharmaceutical production. Additionally, Airplan has the ability to develop production plants and execute expansion and upgrade projects with a focus on energy efficiency.

Versatility has been key to Airplan’s success, establishing it as a benchmark in the sector. This achievement is supported by Autodesk digital tools, such as Revit, BIM Collaborate Pro, and Autodesk Docs.

“The power that Autodesk applications provide us guarantees fast, accurate and up-to-date execution of our projects.”

--—Sergi Jiménez, BIM Manager, Airplan

Reunion. Image courtesy of Airplan

The Challenge of Breaking Down Silos

Defining a methodology for tackling projects with such demanding variables is crucial for the success of applied engineering companies. For Airplan, its commitment to BIM and the cloud emerged as a solution to latency issues.

Initially, all models were stored on servers at Airplan’s headquarters in Barcelona, which caused latency issues at its American offices. The challenge was to find a secure platform accessible to all stakeholders globally, avoiding information silos and enhancing traceability.

Pharmaceutical Plant in Autodesk Revit. Image courtesy of Airplan.

Digital transformation: from physical servers to fully cloud-based operations

Recognizing the potential of digitalization to address these challenges, Airplan embraced full integration between digital documentation and communication by moving from physical servers to the cloud, with Autodesk BIM Collaborate Pro as its new work platform.

The global view enabled by BIM and the cloud is ideal for cleanroom projects, as they integrate standardized components that are digitized into parameterized families, creating a model repository that can be reused in future projects, reducing rework and boosting productivity..

"Exactly 5 years ago we set out to have the best possible “BIM system” and our commitment to Autodesk Revit, Plant 3D, Navisworks, BIM Collaborate Pro and Docs as CDE have become the backbone of the project."

--—José Ferrer, CEO y BIM Strategy Manager, Airplan

Render. Image courtesy of Airplan.

The cloud and BIM: an ideal duo for life science engineering projects

The use of Autodesk BIM Collaborate Pro and cloud-based collaboration solutions has revolutionized communication for Airplan, enabling automated interactions among all project stakeholders. These stakeholders can now access information remotely, allowing them to create, collaborate, and coordinate according to their permissions and project phases. This methodology has increased Airplan’s productivity by 30%, with an estimated potential increase of up to 200%.

In this comprehensive transformation, Airplan has also adopted other Autodesk solutions such as Revit, Plant 3D, Navisworks, and Docs, enabling total project management. These tools support modeling, plan generation, reviews, clash detection, quantification and project progress tracking, among other functionalities. This seamless workflow is enhanced by the use of Industry Foundation Classes (IFC), an independent software exchange format.

Since implementing this transition swiftly, there’s no going back for Airplan. It has established four communication phases among designers, engineers, suppliers, installers and clients to ensure barrier-free collaboration, meeting delivery times, quality standards, regulatory requirements, and technical specifications.