This comprehensive guide explores the fundamentals of material requirements planning (MRP), its evolution, key components, benefits, implementation, and future trends.

Material requirements planning (MRP) is a vital system for manufacturers aiming to optimize production and inventory management. It calculates the materials needed, their required quantities, and the timing for production to operate smoothly. In this guide, we will delve into the fundamentals, including components, evolution, and the significant benefits it brings to your supply chain. We’ll aslo introduce Fusion Operations as an MRP solution.

Understanding material requirements planning (MRP)

Material requirements planning (MRP) is essential for managing inventory and scheduling production. At its core, it helps manufacturers determine the necessary materials for production, their amounts, and the timing for their delivery. This makes sure that the right inventory is available for production when needed, reducing the chances of stockouts or excess stock.

MRP systems use sales forecasts, current inventory levels, bills of materials, and the master production schedule to manage supply. Automating key manufacturing processes with MRP significantly improves efficiency and reduces manual intervention. This enhances production planning, inventory control, and aligns production schedules with customer orders to ensure a smooth manufacturing workflow.

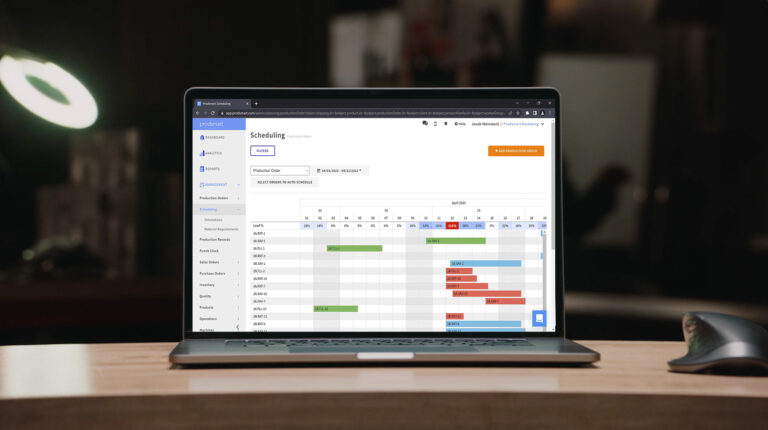

Fusion Operations: Manufacturing Insights at Your Fingertips

Fusion Operations provides real-time data to optimize scheduling, inventory, and quality.

Fusion Operations

Fusion Operations is an advanced MRP solution that evolves with your growth, offering scalability, real-time production visibility, team and resource management, and integrated maintenance management to optimize and future-proof your manufacturing processes.

The evolution of MRP systems

The journey of MRP began in 1964 when Joseph Orlicky implemented the first MRP system at Black & Decker. This marked a significant shift from manual operations to automated processes, helping businesses move away from inefficient ‘just in case’ inventory practices.

Key milestones in MRP evolution:

- 1980s: Introduction of MRP II, expanding the scope to include additional manufacturing processes beyond just materials.

- MRP II enhancements: Inclusion of capacity planning and shop floor control for a more comprehensive approach to production management.

- 1990s: Merging of MRP systems into larger ERP systems, integrating various organizational functions into a unified system.

Today, these systems are more advanced than ever, with IoT and AI technologies making them more predictive and integrated into the entire supply chain. Industries beyond manufacturing, such as healthcare and distribution, are also utilizing MRP to manage supplies and align inventory with customer demand.

Key components

- Master production schedule (MPS): Specifies the products to be manufactured, their quantities, and production timelines.

- Bill of Materials (BOM): A comprehensive list that breaks down the final product into necessary components and raw materials.

- Inventory records: Provide real-time insights into material availability, crucial for effective MRP functioning.

How MRP works

MRP systems work by analyzing inputs such as the Bill of Materials, master production schedules, and inventory records to determine necessary production actions. Real-time synchronization with shop floor systems is essential for effective material planning.

Steps in the process:

- Identifying customer demand and necessary components.

- Checking inventory levels.

- Allocating resources to meet production needs.

MRP outputs:

- Work orders (WO): Describe tasks required to manufacture an item.

- Purchase orders (PO): Detail types, quantities, and prices of materials requested.

- Transfer orders: Instructions for moving inventory.

These outputs provide clear instructions for managing production and inventory control.

Benefits of implementing MRP systems

MRP systems can significantly improve manufacturing processes by streamlining operations, reducing lead times, and enhancing overall efficiency. With optimized production schedules, resource allocation and productivity are greatly improved, ensuring that production efforts align with actual demand.

Modern MRP advantages:

- Adopting demand-driven models, enhancing inventory management and responsiveness.

- Reducing excess inventory and carrying costs.

- Enhancing customer satisfaction through timely deliveries and accurate order fulfillment.

Challenges and limitations

Despite many benefits, traditional MRP systems come with challenges such as ignoring capacity constraints, inaccurate lead time estimations, and data quality issues. Advanced Planning and Scheduling (APS) software addresses some limitations by considering production capacity but still relies heavily on accurate data inputs.

MRP vs. ERP: Understanding the difference

While MRP focuses on inventory and production scheduling, ERP integrates broader functions such as sales, human resources, and finance. ERP systems provide a comprehensive approach to business management, retaining MRP functionalities and centralizing data across business departments for improved efficiency.

Choosing the right system for your business

Selecting the right MRP system involves outlining your specific needs, considering factors such as operation size, customization level, and integration with existing systems. Free trials and expert consultation can help assess the system’s strengths and weaknesses, ensuring it fits your business requirements.

Implementation tips for MRP systems

Effective implementation involves:

- Allocating sufficient time and resources.

- Preparing accurate data.

- Being open to process adjustments.

- Conducting testing phases before full implementation.

- Seeking professional support for a smoother setup.

Future trends in material requirements planning

Future trends include automation, AI-driven resource planning, cloud-based solutions, real-time data access, and predictive analytics. These advancements will enhance decision-making, operational flexibility, and responsiveness to market demands.

Material requirements planning systems are crucial for efficient supply chain management. By understanding the basics, exploring its evolution, key components, and operation, businesses can improve their manufacturing processes and material forecasting.