Modal analysis is an important tool in design and manufacturing processes, ensuring product reliability, performance, safety, and cost-effectiveness. Read on to learn more about what it is, its benefits, and how Autodesk solutions can help.

What is modal analysis?

Modal analysis is a method used in engineering to study and characterize the dynamic behavior of structures and mechanical systems. It involves determining the natural frequencies, mode shapes, and damping characteristics of a structure. These are important for determining how structures will respond to various dynamic loads and vibrational forces. By analyzing these parameters, engineers can predict the vibrational behavior of a structure, identify potential issues, and optimize designs for better performance and reliability.

What is the importance of modal analysis?

Modal analysis offers significant benefits to engineers for serval reasons, including, but not limited to:

- Enhanced safety: By identifying and avoiding resonant frequencies, it helps in designing products that are less prone to failure.

- Improved performance: Understanding the dynamic behavior of a structure allows engineers to optimize the design for better performance, durability, and efficiency.

- Cost savings: Early detection of vibrational issues leads to cost savings by reducing material usage, minimizing maintenance expenses, and avoiding downtime.

- Noise reduction: By identifying and mitigating sources of vibration, modal analysis helps in designing quieter products, improving user comfort and satisfaction.

- Predictive maintenance: It can be used to monitor changes in vibrational characteristics over time, allowing for predictive maintenance. This helps in identifying potential failures before they occur, reducing downtime and maintenance costs.

Industry applications

Aerospace

Modal analysis is applied to aircraft wings, fuselage, and other structural components to predict their response to aerodynamic loads, turbulence, and engine vibrations. This ultimately ensures structural integrity and passenger safety.

Automotive

Engineers use modal analysis on vehicle bodies and engine components to understand and optimize their response to various vibrations and forces, ensuring quieter, more comfortable, and durable vehicles.

Industrial machinery

Study the vibrational behavior of industrial machinery to prevent resonance, improve performance, ensure durability, and enhance user comfort.

Medical devices

Ensure the reliable performance of prosthetic limbs and medical implants under physiological loads. In addition, ensure the proper operation of medical diagnostic equipment like MRI machines and CT scanners.

What to consider when choosing a modal analysis software solution

Selecting the right software solution is important for achieving accurate and reliable results. Key factors to consider include accuracy and precision. The tool should provide high accuracy in calculating natural frequencies, mode shapes, and damping characteristics to ensure that the analysis closely mirrors real-world behavior. A user-friendly interface and intuitive workflow help to reduce the learning curve and improve productivity, so look for software with clear documentation, tutorials, and support resources. Scalability is another key factor to consider; the software should be able to handle different complexity levels, from simple components to large assemblies, ensuring it can grow with your needs. Finally, access to technical support, forums, and a vibrant user community can be invaluable for troubleshooting and advice.

Autodesk solutions for modal analysis

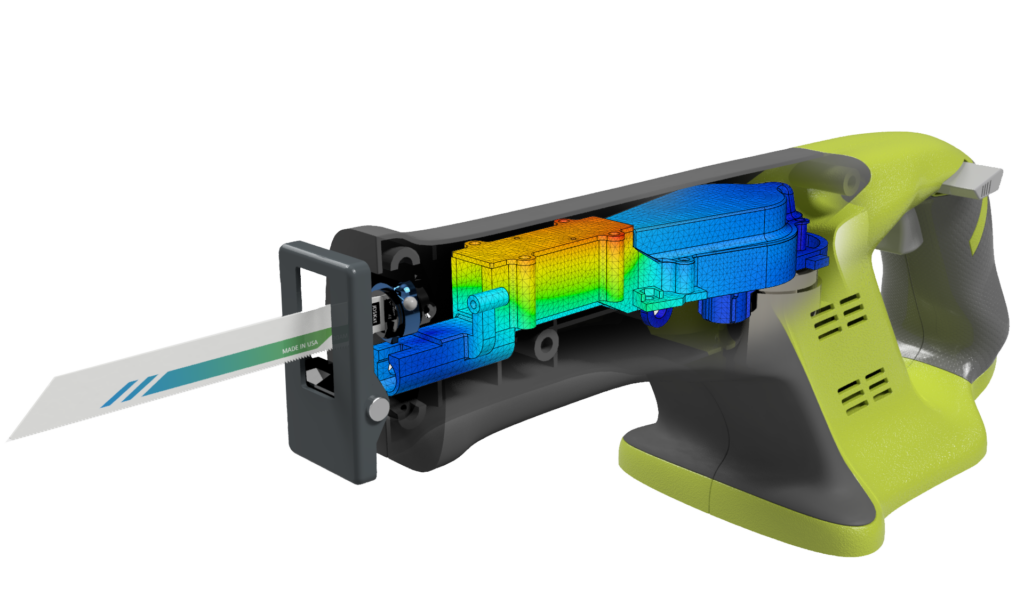

Autodesk Inventor and Autodesk Fusion are great tools for running modal analysis studies. Either solution can help you to review a list of natural frequencies of your design, and it will also display the mode shape for each frequency value. In other words, you can display the animation to review the model behavior. Based on your results, you may decide to add mass to particular areas of your design to increase stiffness. Many of us would like to reduce the weight of our designs, but that is when the natural frequency of your geometry becomes a challenge. After changing your geometry, you can simply run the modal analysis study again with one button click. Then review the results to see if your design has shown improvement.

Conclusion

Modal analysis is a critical tool in engineering and design. It provides valuable insights into the dynamic behavior of structures and mechanical systems. By improving safety, performance, and reliability, and reducing costs and noise, modal analysis aids in the development of robust and efficient products and structures. As technology advances, the importance and applications of modal analysis are likely to expand, further solidifying its role in modern engineering.