Learn about machine design and how Autodesk Inventor provides comprehensive tools for optimizing and streamlining these designs.

Machine design involves creating and developing mechanical systems to perform specific tasks. This process transforms concepts into detailed blueprints for manufacturing, incorporating scientific principles, technical knowledge, and creativity. It makes sure that machines are functional, reliable, and efficient, contributing to industrial development and technological advancement. Let’s take a look at the elements of machine design, its necessity, and learn why Autodesk Inventor is the best solution for machine design.

What is machine design?

Machine design is the process of designing components, devices, and systems to perform particular tasks. It involves applying scientific principles, technical expertise, and creative thinking to develop machines that meet required specifications and carry out intended functions. The primary goal of machine design is to create machines that are functional, reliable, cost-effective, and safe.

Elements of machine design

Machine design encompasses various elements that are essential for creating effective and efficient machines, including:

Mechanical behavior

Mechanical behavior involves understanding how materials and components respond to forces and stresses. This includes studying statics, dynamics, strength of materials, vibrations, reliability, and fatigue. This helps designers make sure that machines can withstand operational conditions and perform reliably.

Machine elements

Machine elements are the mechanical parts used in constructing machines. These include gears, bearings, fasteners, springs, seals, couplings, shafts, spindles, clutches, and brakes. Each element serves a specific purpose and must be designed to function effectively.

Manufacturing processes

Manufacturing processes involve the methods used to produce machine components. This includes casting, machining, welding, forging, and assembling. Understanding manufacturing processes is a necessity for ensuring that machines that can be produced efficiently and economically.

Material selection

Material selection involves choosing the appropriate materials for machine components based on their properties and performance characteristics. Factors such as strength, durability, weight, and cost must be considered so that the machine meets its design requirements.

Why machine design is needed

1. Industrial development

Machines play a vital role in automating processes, increasing productivity, and reducing human labor. Proper machine design makes sure that machines are safe, reliable, and cost-effective, contributing to industrial development and technological advancement.

2. Safety and reliability

Without proper design, machines may fail due to stress, wear, or improper material selection. Machine design ensures that machines can withstand operational conditions, reducing the risk of failure and improving safety and reliability.

3. Cost-effectiveness

Effective machine design optimizes the use of materials and manufacturing processes, reducing production costs and enhancing efficiency. This makes machines more economical in terms of the total cost of production and operation.

4. Innovation

Machine design enhances innovation by enabling the creation of new and improved machines. This drives technological advancement and opens up new possibilities for industrial applications.

Types of machine design

There are a wide range of machines and mechanical systems, each designed to serve a specific purpose. Some common types include:

Conceptual design: This stage focuses on creativity and innovation, exploring different possibilities and determining the feasibility of various designs.

Detailed design: This stage involves precise calculations, material selection, and the creation of detailed drawings and documentation.

Prototype development: This involves creating a working model of the machine to test its functionality and performance. This stage helps identify any issues or improvements needed before full-scale production.

Production design: This stage involves refining the design to ensure that it can be manufactured efficiently and economically.

Procedures

The machine design process typically follows a systematic procedure to ensure that the final product meets all requirements and specifications. The key steps in the machine design procedure include:

1. Problem identification

The first step is to identify the problem or need that the machine is intended to address. It’s important to understand the requirements and constraints of the machine’s intended application.

2. Concept development

This stage involves generating ideas and concepts for the machine, while focusing on creativity and exploring different design possibilities.

3. Feasibility analysis

This includes evaluating the practicality and viability of the concepts developed, while analyzing factors such as cost, materials, manufacturing processes, and performance.

4. Detailed design

Detailed design involves creating detailed drawings and specifications for the machine. This stage includes precise calculations, material selection, and the creation of comprehensive documentation.

5. Prototype development

This stage involves building a working model of the machine to test its functionality and performance. This step helps identify any issues or improvements needed before full-scale production.

6. Production design

Production design focuses on optimizing the machine for mass production and involves refining the design to ensure efficient and economical manufacturing.

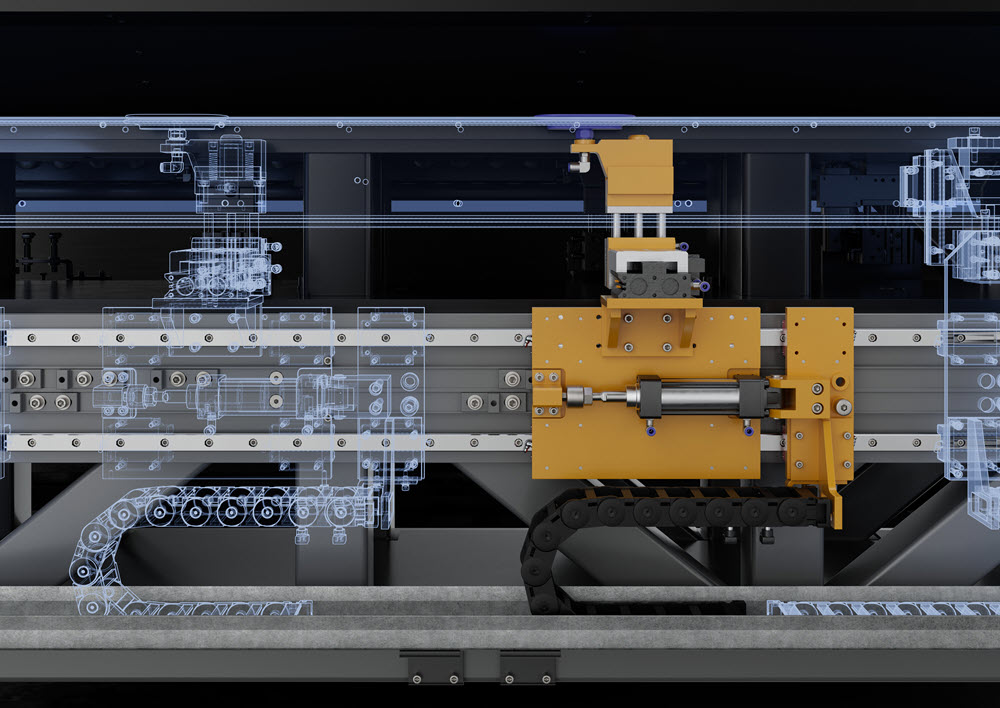

Autodesk Inventor for Machine Design

Enhance Your Engineering Workflows

Precise, powerful, and ready for innovation with Autodesk Inventor.

Autodesk Inventor provides an integrated environment for designing, simulating, and visualizing mechanical systems, making it a fantastic solution for machine design. Here are some reasons why Autodesk Inventor stands out:

- Concurrent design: Multiple team members can design in one central location with simultaneous access to data. This removes bottlenecks by allowing users to edit, comment, and review changes instantly, reducing delays and miscommunication.

- BOM management: Inventor automatically creates a bill of materials (BOMs) from CAD data. This enhances product definition efficiency by ensuring all materials are accounted for, reducing errors and production delays.

- Properties management: Maintain consistency and accuracy across product documentation with predefined industry-standard properties or custom-defined properties. This organized view of product attributes improves collaboration, reduces errors, and accelerates production processes.

- Advanced simulation: Analyze the mechanical behavior of machine components under various conditions to ensure that machines can withstand operational stresses and perform reliably.

- Integrated environment: Inventor provides an integrated environment for design, simulation, and visualization, streamlining the machine design process. This enhances efficiency and productivity, allowing designers and engineers to create innovative and optimized machines.

Machine design is essential for industrial development, safety, reliability, cost-effectiveness, and innovation. Autodesk Inventor empowers designers to create innovative and efficient machines.