Autodesk Inventor

-

Moving from 2D to 3D: A Practical Path with Inventor and AutoCAD

Explore a realistic path to move from 2D to 3D with AutoCAD and Inventor in PDMC. Keep your DWGs while gaining automation, precision, and manufacturing-ready data. For many engineering and manufacturing teams, 2D drawings remain the backbone of daily work. AutoCAD has been a trusted standard for more than four decades, and many organizations have…

Design & Engineering

-

The High Cost of Engineering Bottlenecks: How Autodesk PDMC Reduces Design Cycle Times in Industrial Machinery

Engineering bottlenecks slow industrial machinery manufacturers and increase costs. Learn how the Autodesk Product Design and Manufacturing Collections streamlines workflows, reduce cycle times, and accelerate product delivery. Industrial machinery (IM) manufacturers are constantly faced with high expectations for custom configurations and faster delivery, all while product complexity continue to rise. Engineering teams often struggle with…

Design & Engineering

-

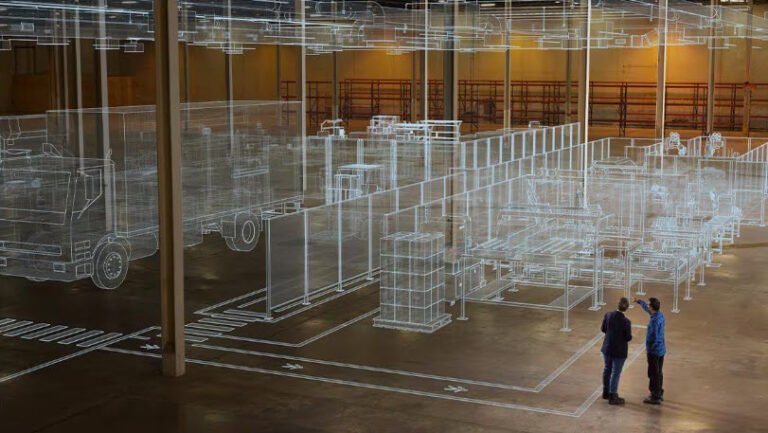

Connecting FDU and FlexSim for End‑to‑End Factory Simulation

Learn how connecting Autodesk Factory Design Utilities (FDU) with FlexSim enables true end‑to‑end factory simulation, improving throughput, reducing risk, and optimizing layout and operations. Production bottlenecks, resource constraints, and unpredictable shifts in demand can derail even the best factory planning. Factory simulation helps address these challenges by revealing how a system behaves under real‑world scenarios…

Production

-

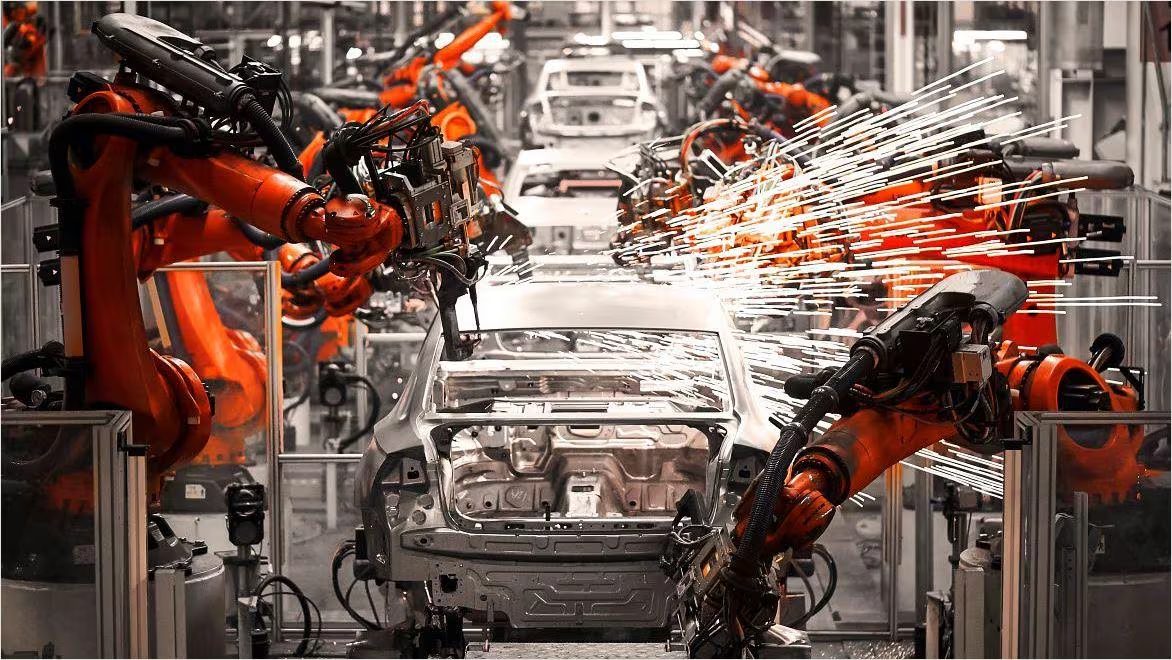

Building Flexible Manufacturing Systems for Unpredictable Markets

This article examines the importance of Flexible Manufacturing Systems (FMS) in navigating volatile markets. It explains how modular and reconfigurable setups help manufacturers pivot production and manage supply disruptions. Learn how Autodesk solutions, like Inventor and Fusion, facilitate agility through automated asset modeling, process simulation, and cloud collaboration. In modern manufacturing, volatility is the norm.…

Production

-

What Are GD&T Symbols and Why Do They Matter?

This article explains the five main categories of GD&T symbols: form, orientation, location, profile, and runout. It details how each category controls specific geometric variations. It also highlights how Autodesk Inventor integrates these symbols into 3D models using Model-Based Definition for automated tolerance analysis. What are GD&T symbols and why do they matter? Geometric Dimensioning…

Design & Engineering

-

Accelerate Time-to-Market and Reduce Risk: The Six Phases of NPI Explained

Learn how structured NPI processes cut time-to-market by up to 50%, improve quality, and enable cross-functional collaboration for manufacturing leaders. Why NPI matters New Product Introduction (NPI) is the structured process that transforms ideas into market-ready products. Companies that implement formal NPI frameworks achieve 30–50% faster time-to-market and 40% fewer post-launch quality issues compared to…

Design & Engineering

-

JIT Management in a Digital Manufacturing World

Explore how AI, IoT, and automation strengthen modern JIT management while addressing challenges related to supplier reliability and uncertain demand. As global supply chains become more interconnected, they become more fragile. In this context, successful just-in-time (JIT) strategies require more than traditional lean practices. They now need digital technologies capable of sensing, predicting, and adapting…

Production

-

Complete Guide to GD&T Symbols: Geometric Dimensioning and Tolerancing

Discover the complete guide to GD&T symbols, their categories, standards, and practical applications across industries. Learn how Autodesk Inventor makes geometric dimensioning and tolerancing easier for beginners, improving design accuracy, manufacturing efficiency, and quality control. Modern manufacturing demands precision beyond basic dimensional tolerances. Engineers rely on GD&T symbols to communicate complex geometric requirements for critical…

Design & Engineering

-

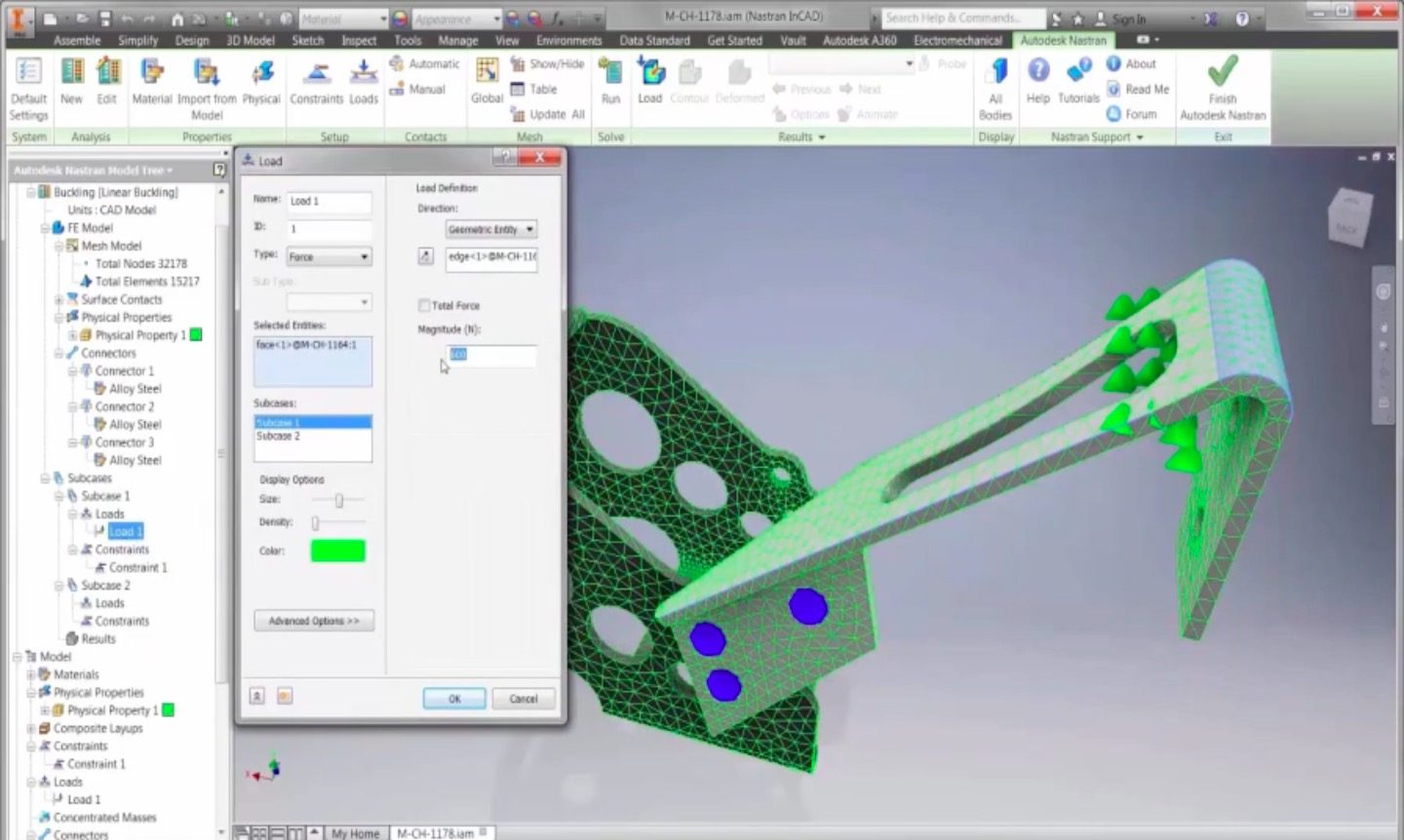

Introduction to Buckling Analysis: What Every Designer Should Know

This article introduces the principles of structural buckling, explains how instability arises under compressive loads, and explores linear versus nonlinear analysis methods. It then highlights how Autodesk Nastran enables detailed buckling simulations within the design workflow, helping engineers identify failure risks and improve performance before physical testing. Buckling is one of the most sudden and…

Design & Engineering

-

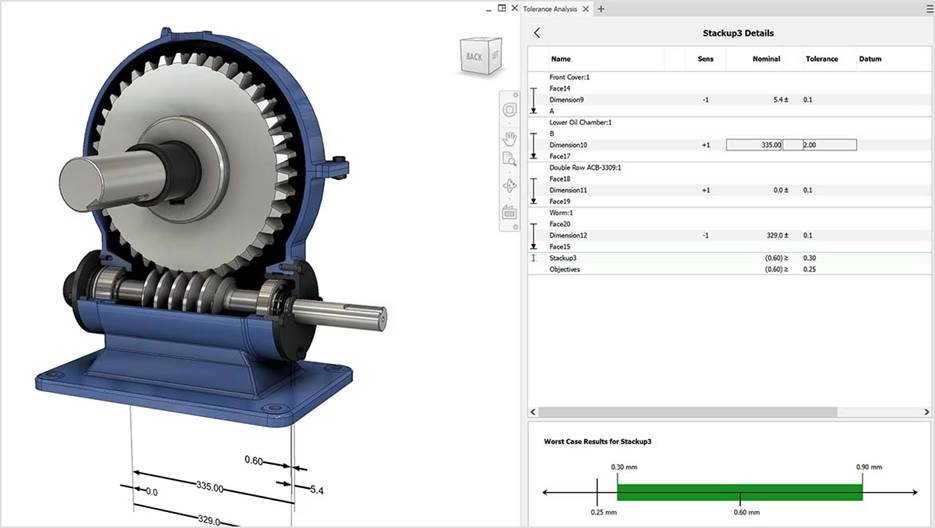

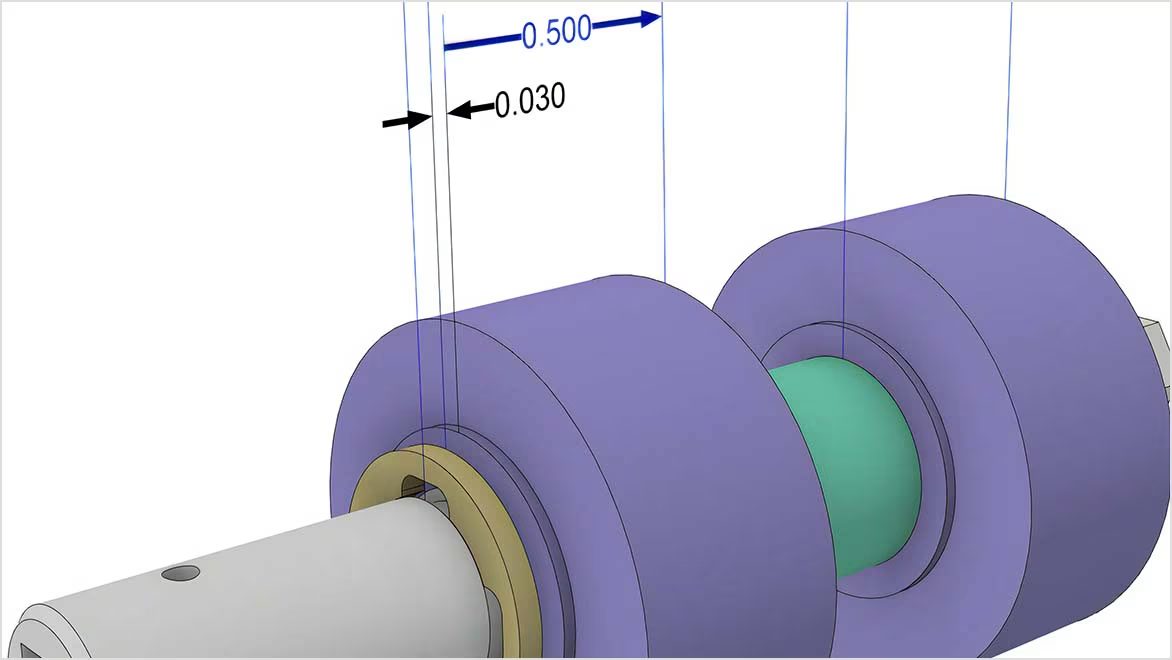

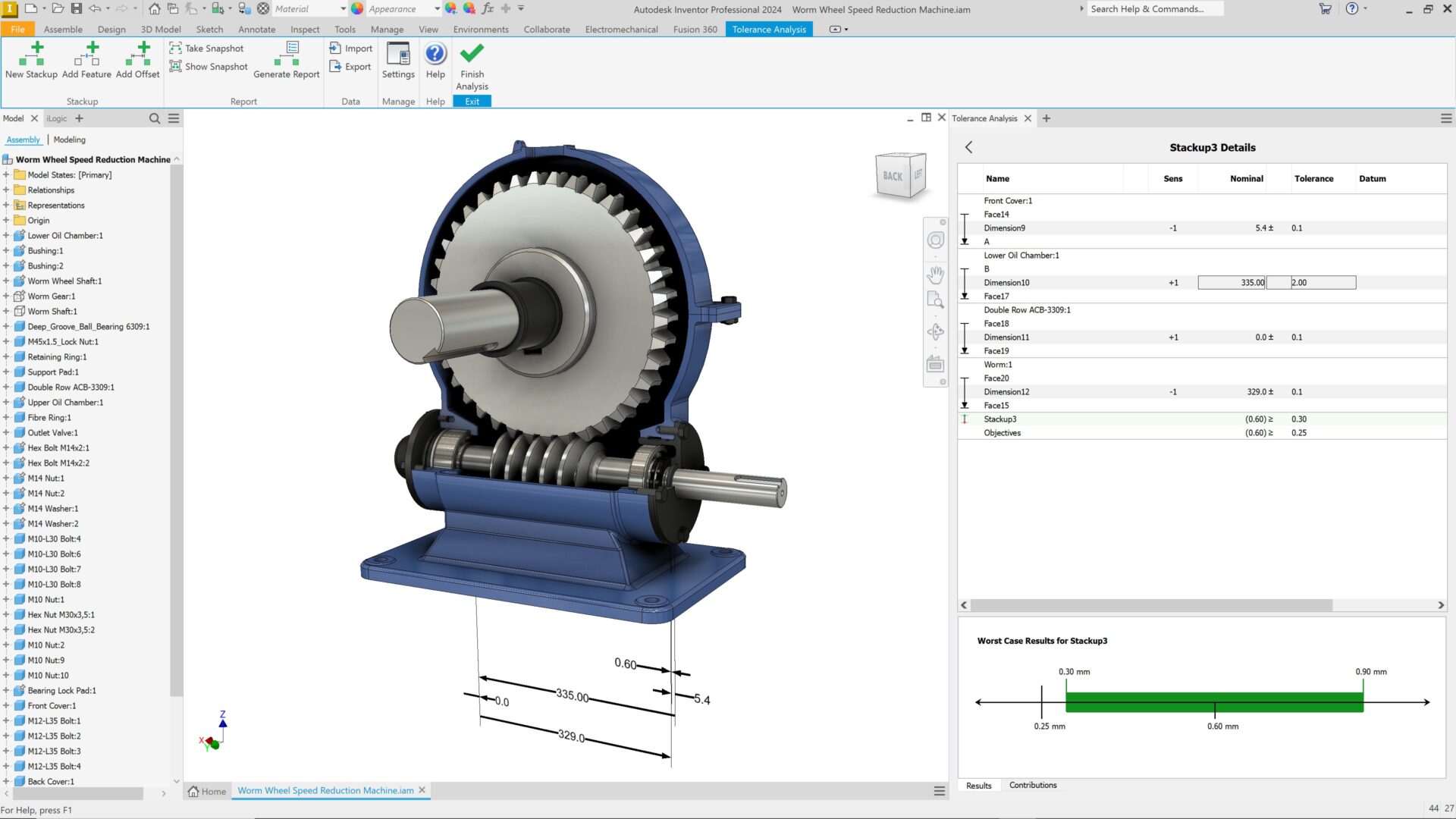

Essentials of Tolerance Analysis for Modern CAD Workflow

This article examines the importance of tolerance analysis in ensuring reliable assembly and controlling manufacturing costs for mechanical design. It discusses how Autodesk Inventor Tolerance Analysis integrates with CAD models so engineers can validate dimensional variation and optimize design decisions early in the workflow. Success in product development is a function of both precision and…

Design & Engineering

-

Inventor 2026.2 What’s New

Inventor 2026.2 is another great point release with several enhancements across the board for sketching, part and assembly modeling, and drawings. Thank you again to everyone who contributed their ideas and feedback for all three of our major releases for Inventor 2026. Assembly enhancements Place and Insert command With Inventor 2026.2, assembling components just became…

Autodesk Inventor

-

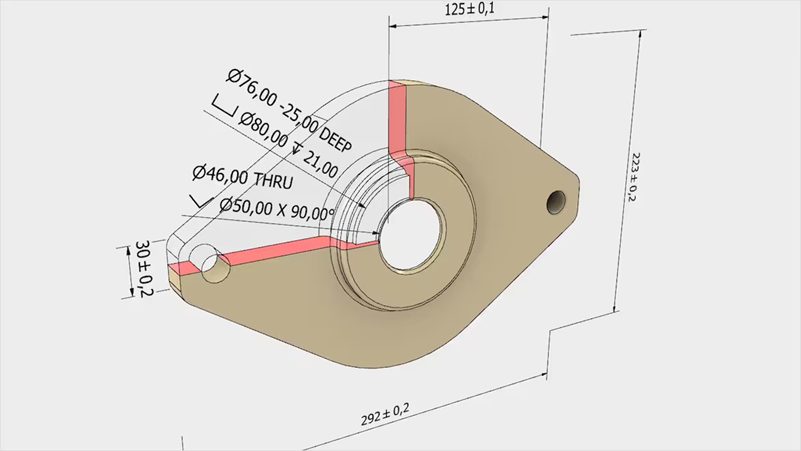

Model-Based Definition (MBD) and The Role it Plays in Modern Manufacturing [Update 2025]

Explore the benefits of model-based definition (MBD), its benefits across manufacturing, and how Autodesk solutions can help. For more than a century, 2D engineering drawings were the universal language of manufacturing. They captured dimensions, materials, and tolerances, serving as the primary reference for turning product concepts into physical parts. As manufacturing technologies and product complexity…

Design & Engineering