Shannon McGarry

Factory design is made easy with Autodesk’s solutions that enhance the process through integrated tools, improving collaboration, efficiency, and overall manufacturing output. Imagine a world where the creation or retrofitting of your next factory translates into enhanced manufacturing output. Construction progresses alongside machine installation and the evolving production line. This is a world void of…

Production

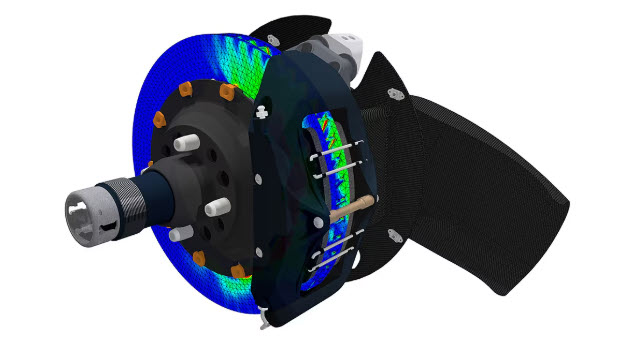

Learn more about how finite element analysis (FEA) enhances product design, safety, and cost-efficiency and how Autodesk solutions can help. Finite element analysis (FEA) is a powerful computational tool for predicting how products react to real-world forces, vibration, heat, fluid flow, and other physical effects. It’s an important part of the design and manufacturing process,…

Design & Engineering

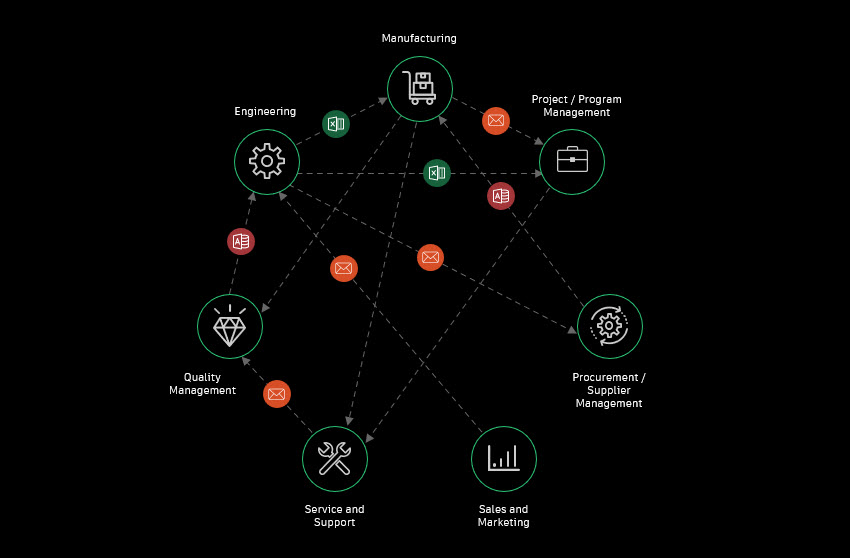

Autodesk Vault PLM enhances data integration across various departments, enabling streamlined processes, improved collaboration, and data-driven decision-making to optimize product development and organizational efficiency. Data is one of the most powerful assets in manufacturing, driving innovation, efficiency, and a competitive edge. While engineering departments have long used data to design and develop products, other departments…

Autodesk Vault

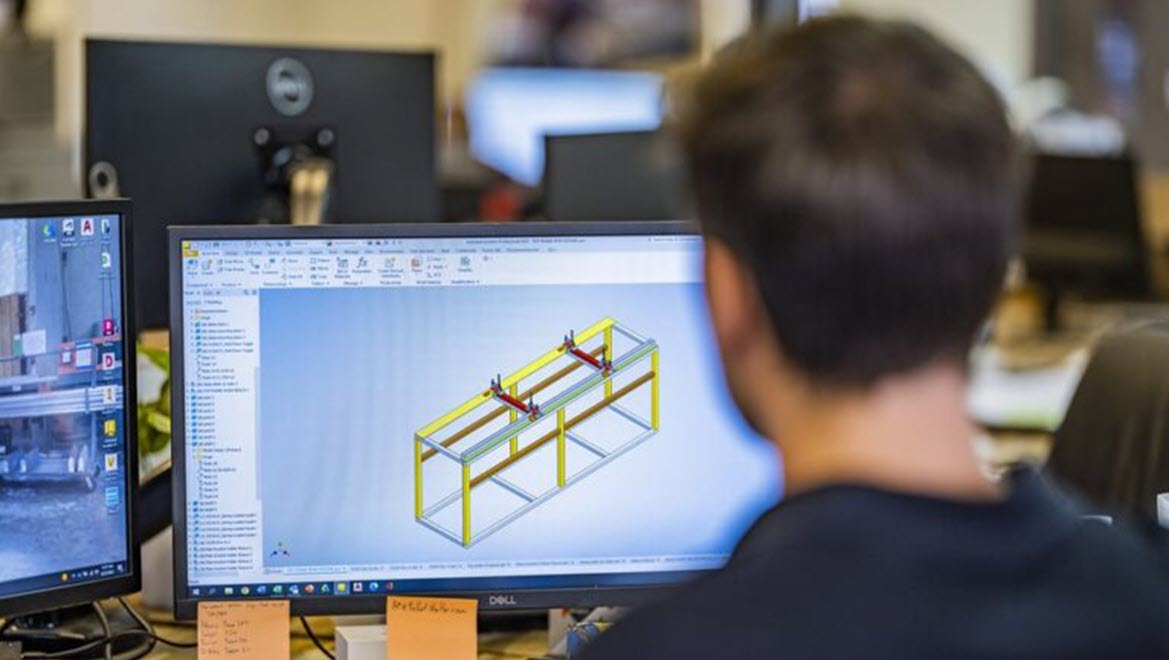

Autodesk Inventor supports design for assembly principles by providing tools that simplify the assembly process, reduce costs, and improve product quality through efficient design practices. Design for assembly (DFA) is a strategic approach in product design focusing on simplifying the assembly process to reduce costs, improve efficiency, and enhance product quality. By implementing DFA principles,…

Design & Engineering

Unlocking efficient BOM management with PLM is essential for modern product development, as it integrates CAD and BOM information, automates workflows, and provides lifecycle visibility, enabling businesses to make better decisions faster and deliver high-quality products efficiently. We’ve all heard the saying “Putting the cart before the horse,” which perfectly explains the way many businesses…

Autodesk Fusion Manage

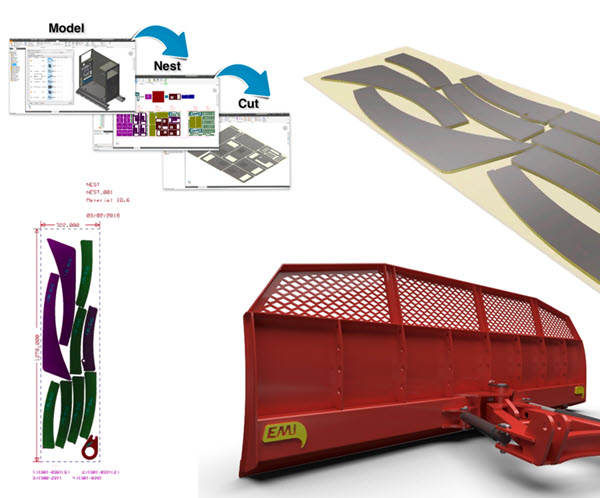

Learn how the PDMC collection, including Autodesk Inventor, AutoCAD, and Fusion can take your manufacturing processes to new heights. From 2D to 3D with the PDMC collection Although 3D design applications have been available to manufacturers for over 20 years, many companies still heavily rely on 2D design. This primarily stems from the fact that…

Design & Engineering

The Autodesk Product Design and Manufacturing Collection offers innovative tools to streamline processes, enhance collaboration, and improve product performance across various industries. What makes the collection so powerful?? The Autodesk Product Design and Manufacturing Collection includes a suite of tools that empower designers and engineers to bring their visions to reality. It provides capabilities that…

Design & Engineering

Engineering data management combines AI-driven processes and cloud-native systems to acquire, organize, analyze, and protect complex engineering data throughout the product lifecycle. Learn how modern EDM transforms manufacturing efficiency, collaboration, and innovation. Engineering data management (EDM) has evolved from simple file storage to become the backbone of modern manufacturing and product development. In 2025, organizations…

Data & Process

Manufacturing process optimization enhances efficiency, reduces costs, and improves product quality through methodologies like lean manufacturing, Six Sigma, and advanced technologies such as automation and Industry 4.0. Manufacturing process optimization for efficiency Manufacturing process optimization is not just a strategic advantage; it’s a necessity driving manufacturing optimization that balances cost, quality, and speed. Optimizing manufacturing…

Production

Embracing digital transformation in 3D engineering is essential for future growth and competitiveness, enabling enhanced collaboration, improved data management, streamlined workflows, and innovative solutions through tools like Autodesk Inventor. 3D engineering has evolved significantly over the past few decades. These changes have been primarily driven by technological advancements and the increased demand for more efficient,…

Design & Engineering

Establishing a new factory is a complex investment requiring meticulous planning, collaboration, and execution. Learn how Autodesk’s digital factory solutions can help. Standing up a new factory is most likely the largest single investment a company can make. This massive undertaking involves extensive planning, collaboration, and execution. Despite rigorous planning processes, companies often face cost…

Production

Explore four major trends in digital manufacturing—automation, digital twins, sustainability, and workforce digitization—and see how Autodesk solutions help factories implement and scale these innovations. Since the first industrial revolution, factories have continued to evolve at a rapid pace. In 2025, factories are increasingly defined by their digital tools and ability to perform data-driven decisions. Currently,…

Production