Shannon McGarry

Discover how ATL Technology unified global design and manufacturing operations with Autodesk Fusion Manage, transforming fragmented systems into a centralized, scalable PLM platform. Operating across multiple continents, ATL Technology struggled with inconsistent systems, disconnected data, and uneven process maturity – creating serious roadblocks as the company grew. By adopting Autodesk Fusion Manage, the global medical…

Data & Process

Poor version control in manufacturing causes rework and missed deadlines. Discover how Autodesk Vault stops outdated data from draining profit. Engineering teams never intend to design from outdated data. Yet in shops that still rely on shared drives, email threads, and tribal file‑management habits, it happens every single day. What looks like a small annoyance…

Data & Process

Discover how optimized material handling strategies—such as zoned presorting, batching, and workflow redesign—can significantly increase warehouse throughput with Autodesk FlexSim. Introduction: Why material handling drives warehouse performance Material handling is one of the most influential factors affecting operational success in today’s distribution centers. In facilities that span hundreds of thousands of square feet, every second…

Production

Discover agile project management principles, frameworks, and benefits, plus how Autodesk solutions enable agile practices in design and manufacturing. Traditional project management approaches often struggle to keep up with shifting priorities, evolving customer needs, and rapid technological changes. Agile project management methodologies have emerged as a powerful alternative, enabling teams to deliver value faster, adapt…

Uncategorized

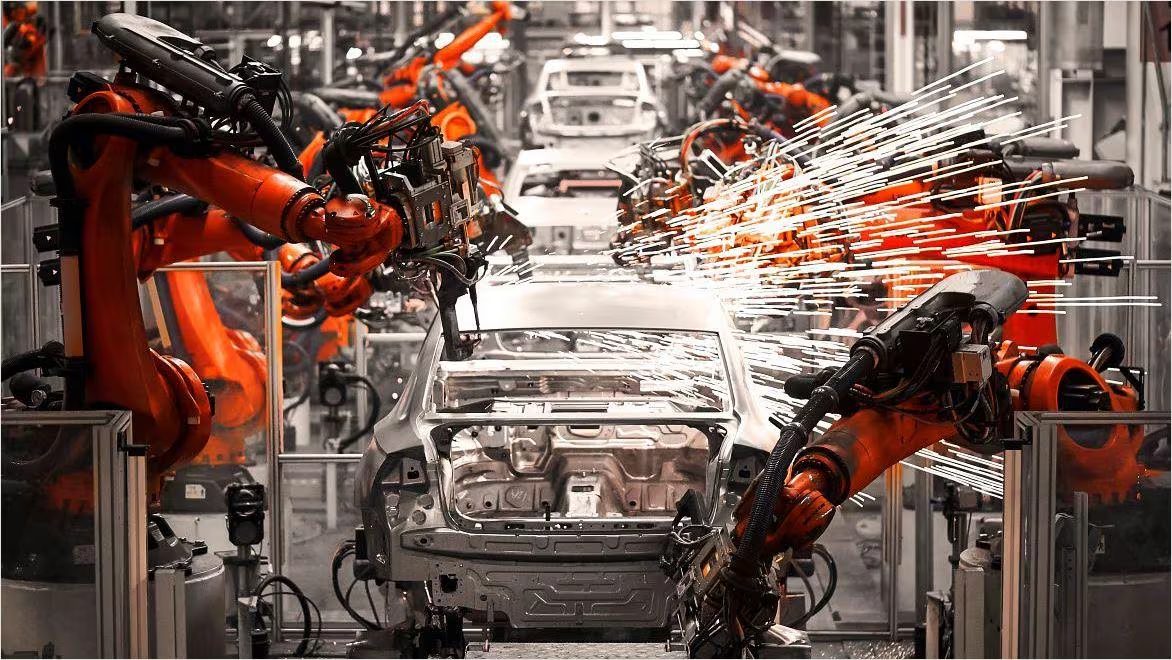

This article examines the importance of Flexible Manufacturing Systems (FMS) in navigating volatile markets. It explains how modular and reconfigurable setups help manufacturers pivot production and manage supply disruptions. Learn how Autodesk solutions, like Inventor and Fusion, facilitate agility through automated asset modeling, process simulation, and cloud collaboration. In modern manufacturing, volatility is the norm.…

Production

Learn how structured NPI processes cut time-to-market by up to 50%, improve quality, and enable cross-functional collaboration for manufacturing leaders. Why NPI matters New Product Introduction (NPI) is the structured process that transforms ideas into market-ready products. Companies that implement formal NPI frameworks achieve 30–50% faster time-to-market and 40% fewer post-launch quality issues compared to…

Design & Engineering

Explore how AI, IoT, and automation strengthen modern JIT management while addressing challenges related to supplier reliability and uncertain demand. As global supply chains become more interconnected, they become more fragile. In this context, successful just-in-time (JIT) strategies require more than traditional lean practices. They now need digital technologies capable of sensing, predicting, and adapting…

Production

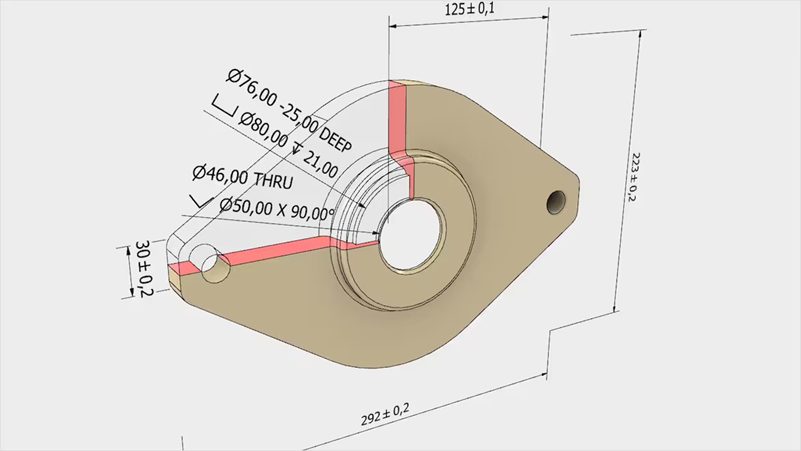

Discover the complete guide to GD&T symbols, their categories, standards, and practical applications across industries. Learn how Autodesk Inventor makes geometric dimensioning and tolerancing easier for beginners, improving design accuracy, manufacturing efficiency, and quality control. Modern manufacturing demands precision beyond basic dimensional tolerances. Engineers rely on GD&T symbols to communicate complex geometric requirements for critical…

Design & Engineering

Discover how Spirax Group boosted global collaboration and efficiency with Autodesk Fusion Manage, the cloud PLM solution for modern manufacturing. At Spirax Group, innovation is at the heart of everything they do. With three niche businesses operating in the thermal energy and fluid path technology sectors, they design and manufacture industrial valves, pumps, and a…

Autodesk Fusion Manage

Real time location systems for manufacturing provide real-time tracking and data integration in order to optimize asset utilization, inventory management, production efficiency, safety, and decision-making. This positions RTLS in manufacturing teams for data-driven success. RTLS for manufacturing In the fast-evolving world of manufacturing, staying competitive means constantly seeking ways to enhance efficiency, accuracy, and productivity.…

Data & Process

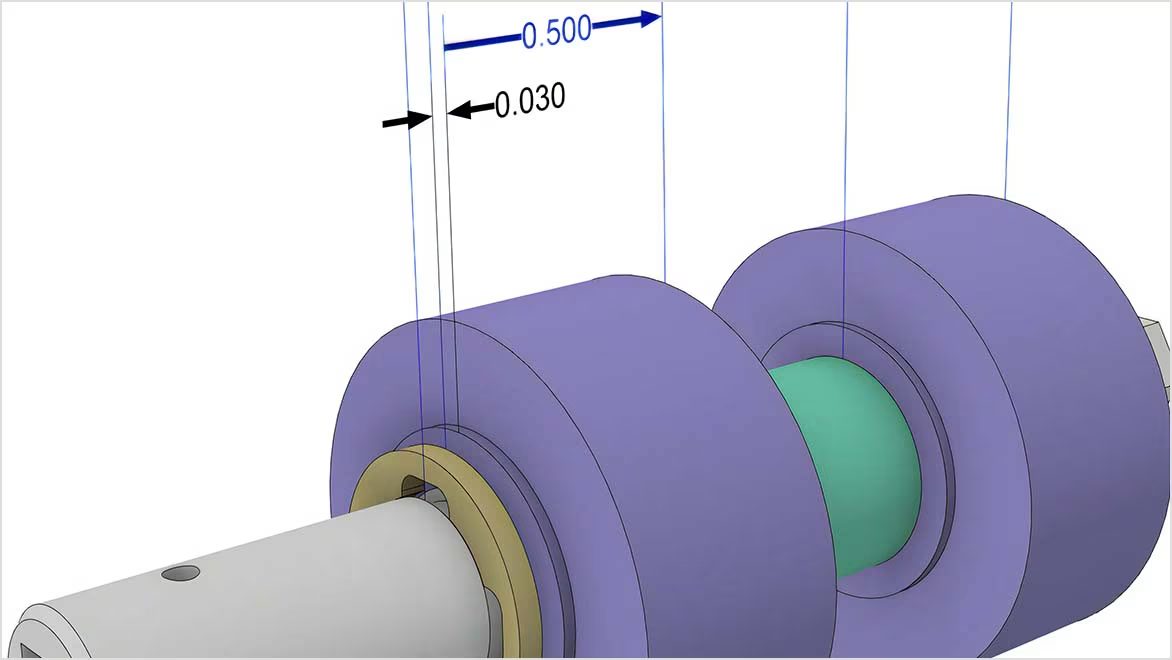

This article examines the importance of tolerance analysis in ensuring reliable assembly and controlling manufacturing costs for mechanical design. It discusses how Autodesk Inventor Tolerance Analysis integrates with CAD models so engineers can validate dimensional variation and optimize design decisions early in the workflow. Success in product development is a function of both precision and…

Design & Engineering

Discrete event simulation (DES) enables manufacturers to analyze, model, and optimize complex production systems without disrupting real-world operations. As the manufacturing ecosystem grows more dynamic—with variables like supply chain volatility, custom product demands, and automation—DES provides a virtual sandbox for experimentation, forecasting, and cost optimization. How discrete event simulation (DES) & modeling helps manufacturing make…

Autodesk FlexSim