Ellie Rathbone

Social Media Marketing Specialist at Autodesk, managing all advanced manufacturing social channels across multiple platforms. Based in the UK.

Additive manufacturing is a process that creates solid objects from a computer-generated design. The digital model is divided into different layers and an actual product is built layer-by-layer until the final, desired output is obtained. An example of a process which uses these manufacturing principles is 3D printing, which is gaining popularity around the world.…

Advanced Manufacturing

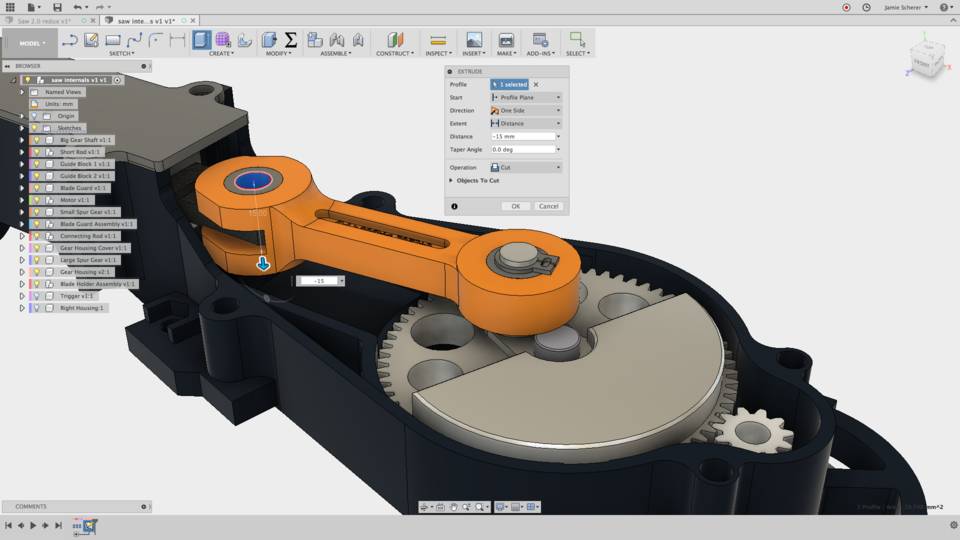

Collaboration is one of the most important factors that can determine the success of a business in today’s hyper-competitive global market. Ideas and professional expertise from around the world can be used together to solve highly complex problems in the engineering field. Collaborative software such as Fusion 360 has been designed to make this process…

Advanced Manufacturing

Modern manufacturing has been characterized by the rise of the machines. Gradually, robots have replaced human workers on assembly lines, carrying out repetitive tasks that are easy to replicate. For example, on vehicle production lines a robotic arm can hold a car door in place, while another bolts it to the frame. The automation of…

Advanced Manufacturing

Evolution is a powerful thing. It’s the driving force behind life as we know it. With the technology available to us today, it was only a matter of time before the power of evolution was harnessed to shape the material world too. Generative design is an automated, iterative approach to design that uses the power…

Advanced Manufacturing

Virtual Reality (VR), and its close relatives – Augmented Reality (AR) and Mixed Reality (MR), have seen significant advances over the past few years. Oculus Rift and PlayStation have brought VR to the gaming community, but the possibilities extend much further than just creating immersive video game experiences. To clear up any confusion, VR is…

Advanced Manufacturing

The process of designing and manufacturing products is no longer confined to the real world. Technological advances in computing and visualization devices mean that it is now possible to use virtual reality (VR), augmented reality (AR) and mixed reality (MR) to help design teams create products that would have been inconceivable not so long ago.…

Advanced Manufacturing

Computer-aided manufacturing (CAM) is used to design and manufacture products. It can enhance repetitive processes such as drilling holes or cutting layers. The manufacturing process automatically converts design drawings into machine-friendly codes. This allows the machine to read the design and then manufacture the product according to the design specifications. How does it work and…

Advanced Manufacturing

Although there are dozens of CAM systems available, choosing one is not as difficult as many believe. It comes down to choosing the best one for your application. This paper is meant to help give you the tools to help pick the best one for you. Consider the packaging CAM software is available in three…

Advanced Manufacturing

One of the most important things to consider when you’re looking to create a mold is surface finish. No matter what material or method is being used to create your mold, whether you’re machining or using an EDM system or another form of mold making, the surface finish of your mold will always affect the…

Advanced Manufacturing

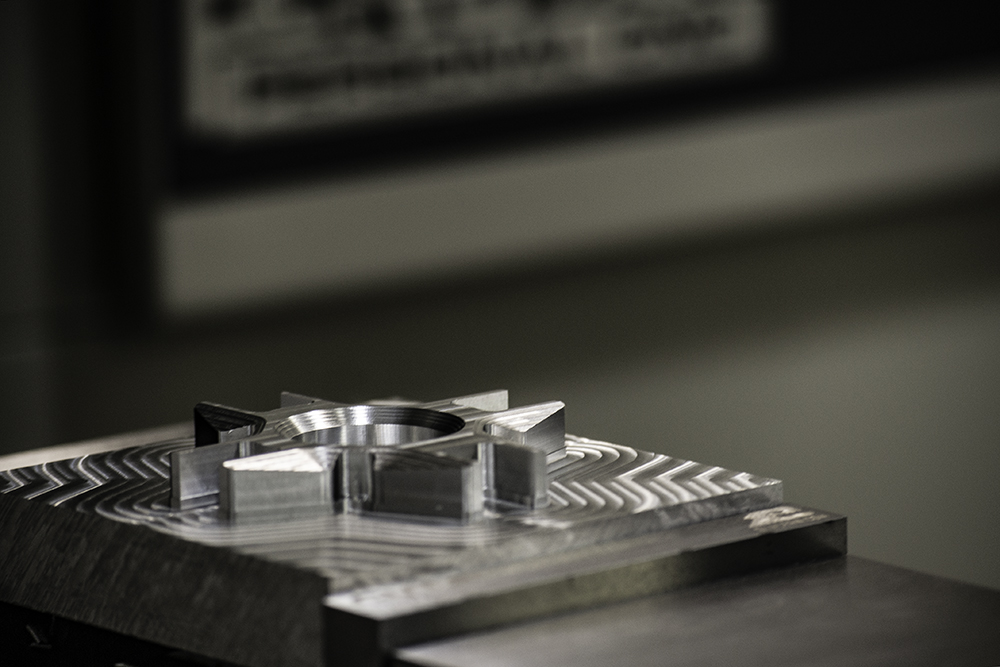

Many different manufacturing processes are used to actually manufacture tooling for mold making. Most mold making involves CNC machining, or subtractive processing of the material. Other operations besides milling are used, including 3D printing and EDM operations. Moldmakers today are under pressure to create their mold tooling faster than ever before. Although EDM manufacturing is…

Advanced Manufacturing

Traditionally, 5-axis mills were built and marketed for the domain of aerospace and power generation manufacturers. However, the adoption of 5-axis machining centers has increased for moldmakers in recent years. It is the purpose of this article to provide some information if shopping for a 5-axis mill for moldmaking. Advantages There are many advantages to…

Advanced Manufacturing

Dealing with five axes when machining isn’t a simple process in any industry, but it gets especially interesting in the realm of aerospace. When we’re talking about subtractive manufacturing in general, you have to consider everything from your material and holding that work to your tooling and the toolpaths to get to your finished part.…

Advanced Manufacturing

For machine shop operators considering milling machines, one of the most basic questions they have to answer relates to configuration: vertical or horizontal mill? The answer depends on the nature of the business—in particular the type and volume of work being done in the shop—but also cost, capabilities of the workforce, and the facility itself. All…

Advanced Manufacturing

In the constantly evolving world of manufacturing, mold and die shops must continually improve productivity without sacrificing part quality. As you strive to stay competitive, you may need to work smarter and harder… With harder materials, that is. Many molds and dies require these hard materials to operate optimally. For example, H13 steel is capable of…

Advanced Manufacturing

A look at how one mold manufacturer has embraced new manufacturing technology, unlocked the full potential of its workforce and become the dominant supplier in its field. Article by Clinton Perry, PowerMill Product Marketing Manager Today’s mold manufacturers are under pressure. Yep, it’s a shock revelation, right? Your end customers demand, even expect, to see…

Advanced Manufacturing