Alexander Oster

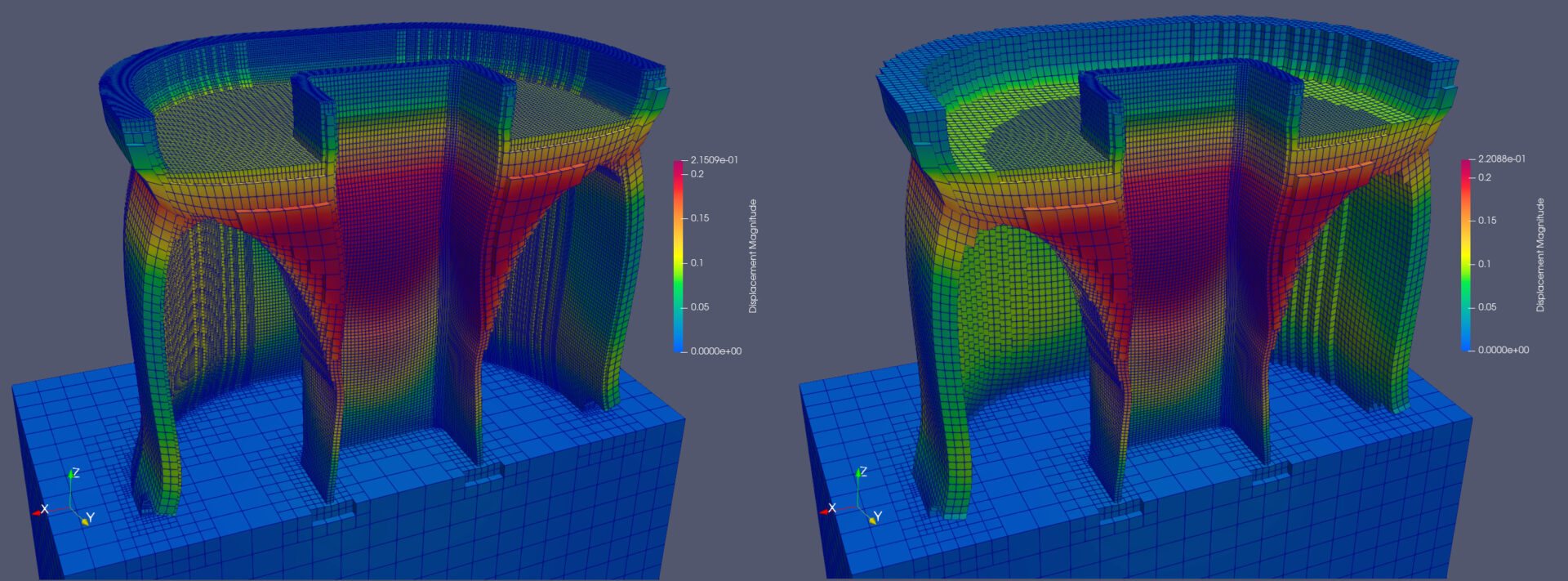

Learn how to speed up thermo-mechanical additive process simulation by an order of magnitude. Additive process simulation uses first principle physics to predict how a metal 3D printing process behaves. It outputs the full temperature history of a selective melting process, as well as the deformation that those temperatures cause at each time during and…

Fusion

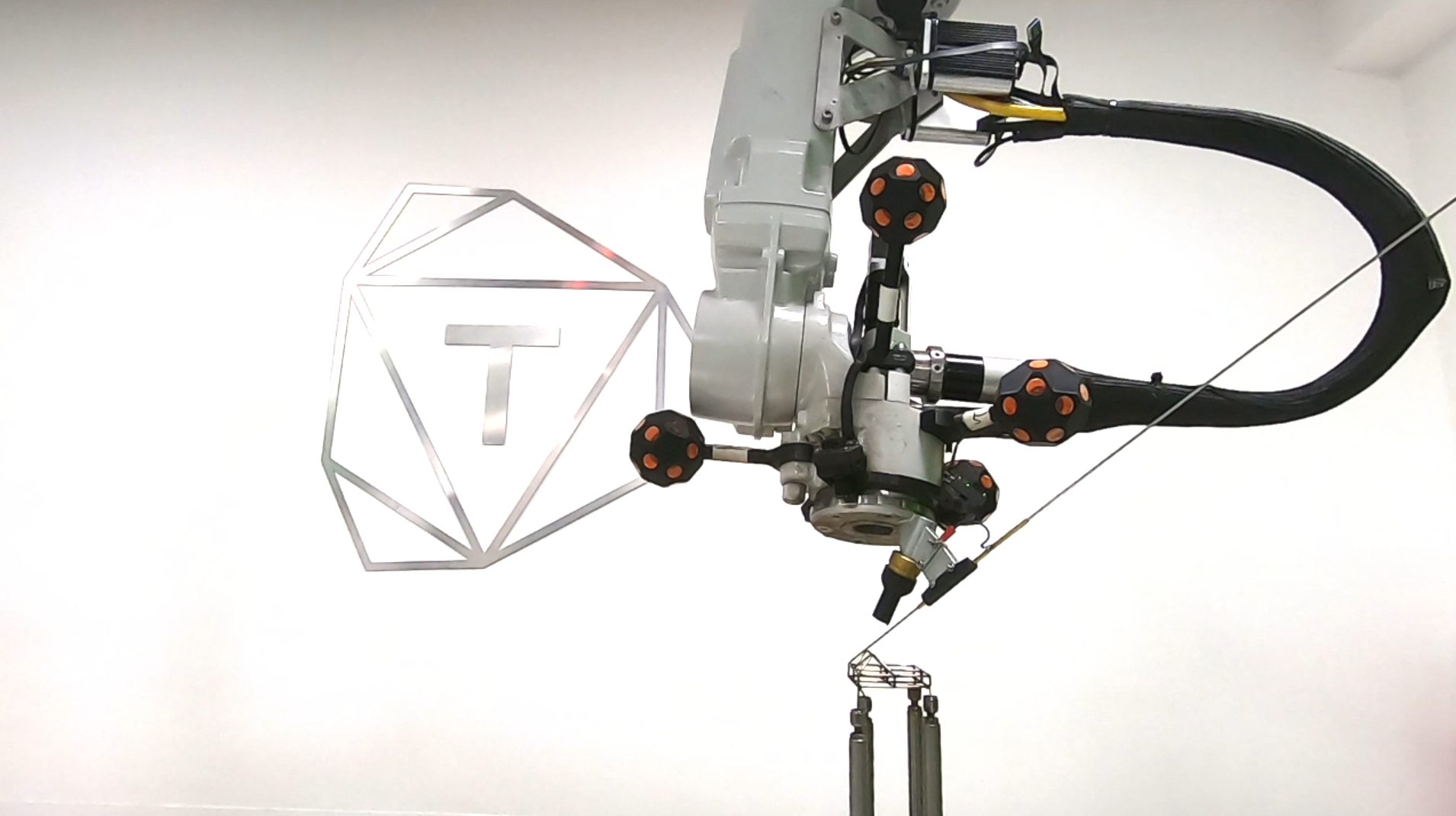

TETMET’s Lattice Design Suite, integrated with Autodesk Fusion, enables AI-driven robotic welding to create large, efficient, lightweight lattice structures. Over the last few years, TETMET, a company based in Paris and Amsterdam, has focused on solving a key challenge – How to build large, lightweight metal or polymer lattice structures without the high costs, volume…

News

Autodesk and SCANLAB have created a real-time closed-loop control system for laser powder bed fusion processes, enhancing precision and efficiency in additive manufacturing.

Manufacturing

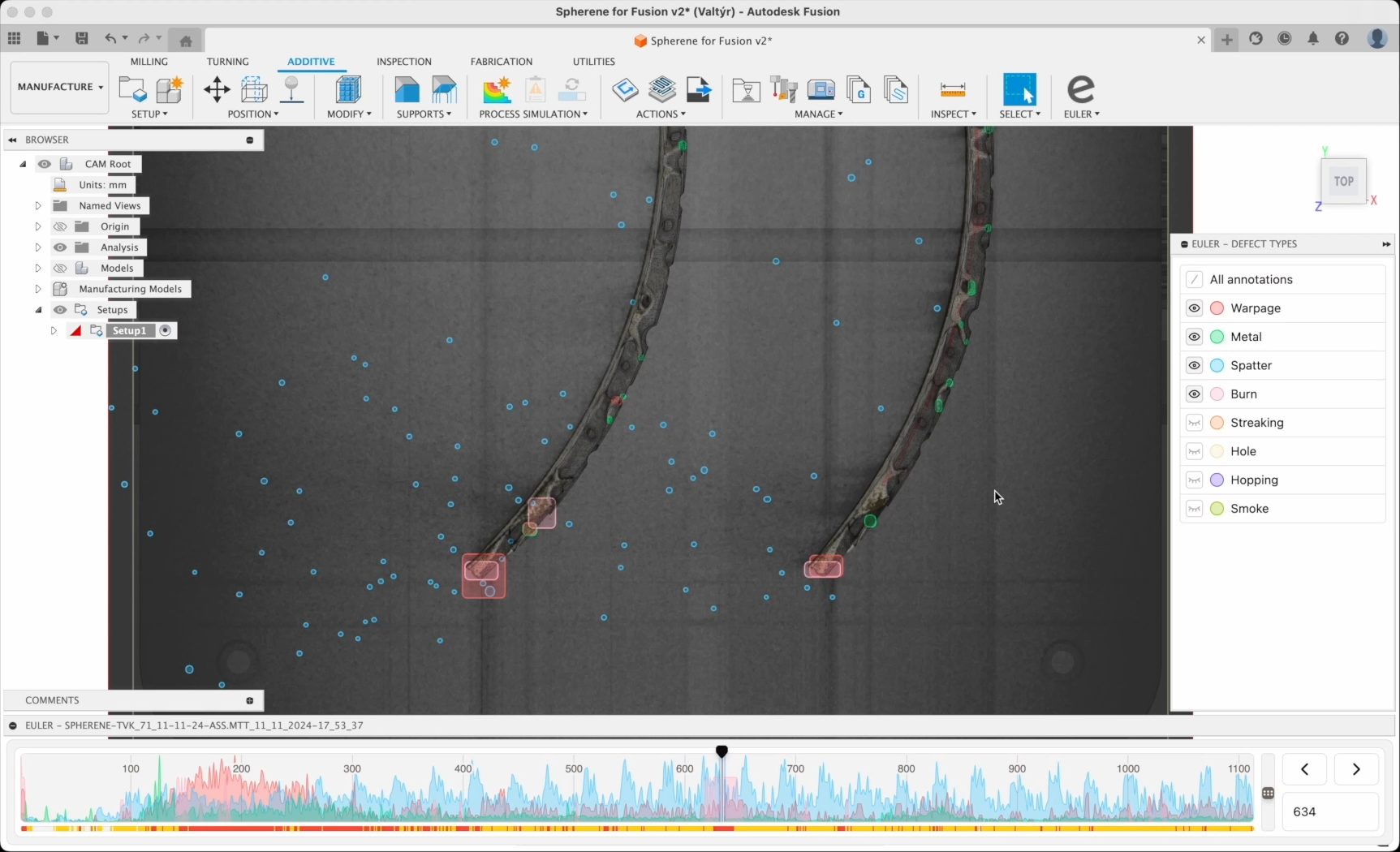

Integrating process monitoring data into the design workflow, as demonstrated by AI startup Euler on the Autodesk Fusion platform, enhances additive manufacturing with real-time defect detection, failure prediction, and actionable insights, bridging the gap between design and manufacturing for practical, manufacturable designs. Euler, an Iceland-based AI startup, specializes in computer vision and anomaly detection for…

Manufacturing