Fifteen years ago, Joint Design Direction (JDD) began when two long-time friends, James Mercy and Joe Duffell, reconnected over a drink during the Christmas holidays. They first met in secondary school when they were 11 years old. After they studied design at separate universities, they both pursued careers in the design industry, albeit in different roles.

That one evening catch-up was fortuitous. James and Joe decided to combine their experiences and embark on their own furniture design journey.

Without any external funding, they scraped together some money to get started. Their first launch pad was at the famous 100% Design (now Design London) trade show in London, where they showcased JDD in an area for new companies. At their stand, James and Joe met the architects furnishing Google’s headquarters in Europe, West Asia, and Africa. They were having issues sourcing certain products, such as high-back sofas, and asked JDD if they could help. Of course, it was an immediate yes. James and Joe said yes to everything and, “we’d figure it out later,” James says.

“Our passion was for design, but we didn’t even know we were going to go into office furniture design before that,” James says. “It gave us the direction to where we are today.”

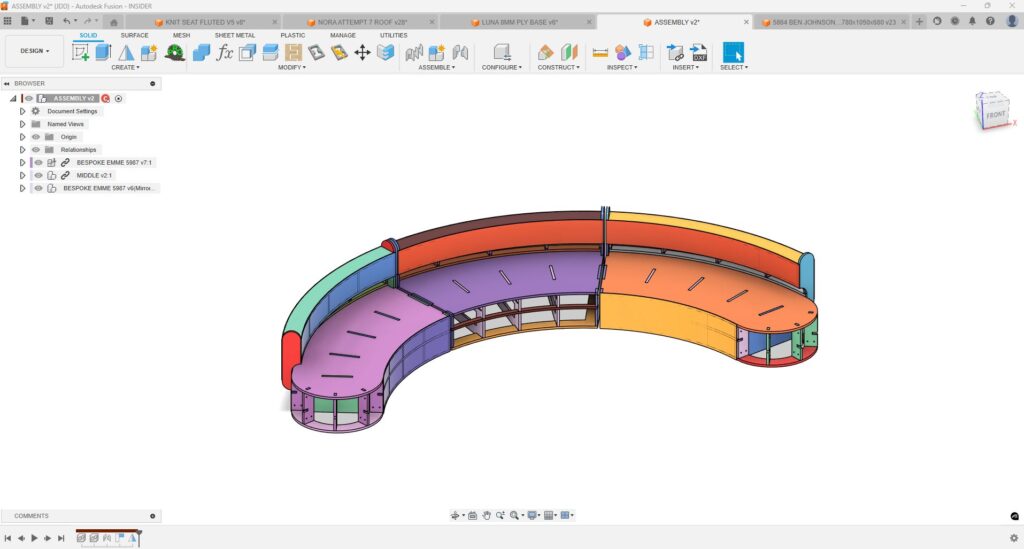

JDD now boasts more than 30 standard products, from privacy pods to sofa dens, seating, banquettes, and a brand-new sleep pod. With all design and manufacturing based in the UK, they provide both their standard products and customized versions to companies around the world. The business is booming with more than 90 employees; a full-scale design and manufacturing facility at their headquarters in Dudley, England (the home of the Peaky Blinders); and showrooms in Birmingham, London, Glasgow, and Dubai.

To keep up with new demands and grow the business even further, they recently adopted Autodesk Fusion to help bring beautiful and functional furniture solutions to life even more quickly and efficiently.

Solving design and business challenges with Fusion

A combination of factors led the JDD team to Fusion. Their designs were becoming more complex, and their manufacturing capability was growing rapidly. 3D modeling in AutoCAD was proving too difficult, especially with bespoke customization. A year ago, they started using Fusion and haven’t looked back. Now their entire design-to-manufacturing workflow is optimized and already making a huge difference.

“Clients might want different widths, depths, or heights for the products, and that’s easily done with the parametric modeling in Fusion,” says Charlie Adlem, production designer, JDD.

“Something that might have taken maybe three hours in AutoCAD takes three minutes now with Fusion,” adds George Hopkins, production designer, JDD. “That was why we committed to the change.”

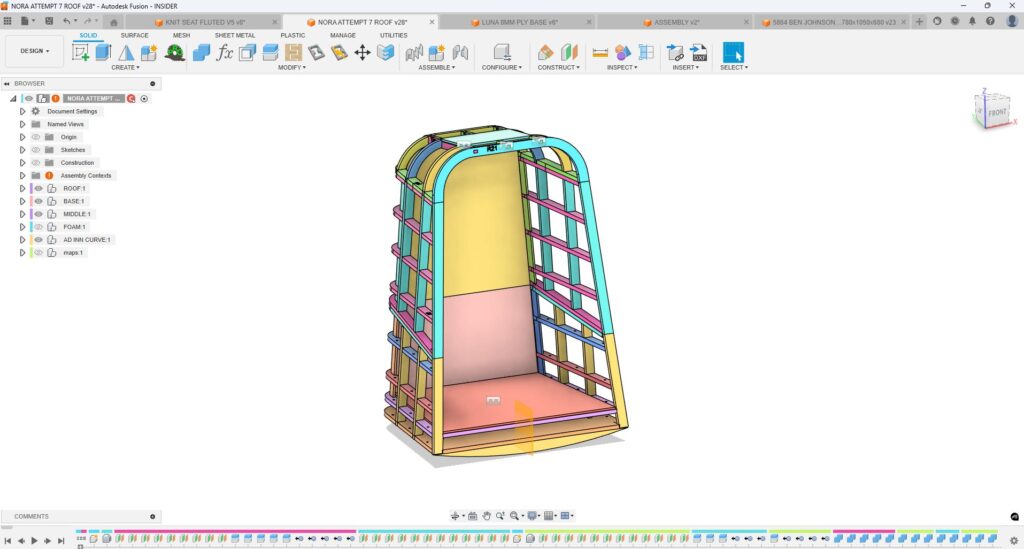

“For the design of our new rest pod, Fusion was particularly helpful. During prototyping, we might need to adjust the design to make something wider to fit or determine the standardization of the mattress. Parametric modeling came in handy. It’s a click of a button rather than redrawing the whole thing.”

—Charlie Adlem, Production Designer, JDD

Moving over to Fusion for furniture design

On the design side, Henry, product designer at JDD, has also moved over to Fusion. Previously, he was modeling in 3ds Max and testing with OnShape. When he needed to share a CAD file with Charlie or George, he provided either STEP files or just 2D drawings.

“It really made sense for me to move into the same software with Fusion because now we can just share the documents and models,” Henry says. “When you share a STEP file, you lose all the history, notes, and little nuances because you’re just exporting it as a dumb file. Then Charlie and George would have to rework it, and there was a lot of unnecessary back-and-forth communication. Now everything is there in one place. I’ve only started using Fusion, but it’s really sped up the process already.”

Ease-of-use reigns supreme

For JDD, Fusion’s ease-of-use is, well, easily their favorite aspect of using it. Plus, it provides the opportunity to push the boundaries of frame making and accuracy.

“I’ve used other software in the past, like SolidWorks and Rhino, and they seem so complicated compared to Fusion,” Charlie says. “The user interface and icons are easy to use. The tools in Fusion are easy to pick up, and there are loads of tutorials online.”

JDD has also discovered new ways to collaborate—even down to the factory floor. “Before we’d have to do drawings for the wood mill and the person assembling it,” George says. “But now we share the file link, and they can just open it up on a tablet or a phone. It makes the process much faster.”

Bringing in fresh perspectives

JDD is also committed to a student placement program that they’ve found mutually beneficial. Students can train and learn more about Fusion and design while JDD gains access to a potential talent pool and unique perspectives from Gen Z.

“They really do come with fresh ideas and are a little bit more clued in on what’s happening outside of our industry in terms of trends that they can apply to their design work here,” Henry says.

JDD recently had a four-month placement, and another student will start this fall. She’ll be at the company for a full year with the opportunity to be involved in every aspect of the business, including coming up with her own design idea, using Fusion, working on the development side, and simply roaming around the business to learn from other teams, too.

One former student placement, Dominic Boniface, didn’t even want to leave at the end of his engagement. JDD (and his parents) encouraged him to return to university and finish his last year.

“Dominic came back after graduation, and he has been an invaluable asset to the company with the work he does and the commitment he has,” James says. “It’s a great way to find people that are very talented and otherwise might not have looked at JDD.”

Looking forward

JDD’s current design focus is on wellness, whether it’s for the workplace or the public sector, such as libraries, universities, and more. Since the successful launch of their new Yume Rest Pod and Nita, the JDD team is dreaming up even more ideas to bring wellness to those environments. As they scale the company and these latest designs, they have a strong foundation with Fusion.

“It’s all about the team’s workflow at the end of the day, and using Fusion is making an impact for them,” James says. “My positives are their positives. As long as things make their jobs easier or more efficient and enjoyable, then that’s a win for me. If using Fusion helps them, it helps the company.”