-

What Are GD&T Symbols and Why Do They Matter?

This article explains the five main categories of GD&T symbols: form, orientation, location, profile, and runout. It details how each category controls specific geometric variations. It also highlights how Autodesk Inventor integrates these symbols into 3D models using Model-Based Definition for automated tolerance analysis. What are GD&T symbols and why do they matter? Geometric Dimensioning…

Design & Engineering

-

Accelerate Time-to-Market and Reduce Risk: The Six Phases of NPI Explained

Learn how structured NPI processes cut time-to-market by up to 50%, improve quality, and enable cross-functional collaboration for manufacturing leaders. Why NPI matters New Product Introduction (NPI) is the structured process that transforms ideas into market-ready products. Companies that implement formal NPI frameworks achieve 30–50% faster time-to-market and 40% fewer post-launch quality issues compared to…

Design & Engineering

-

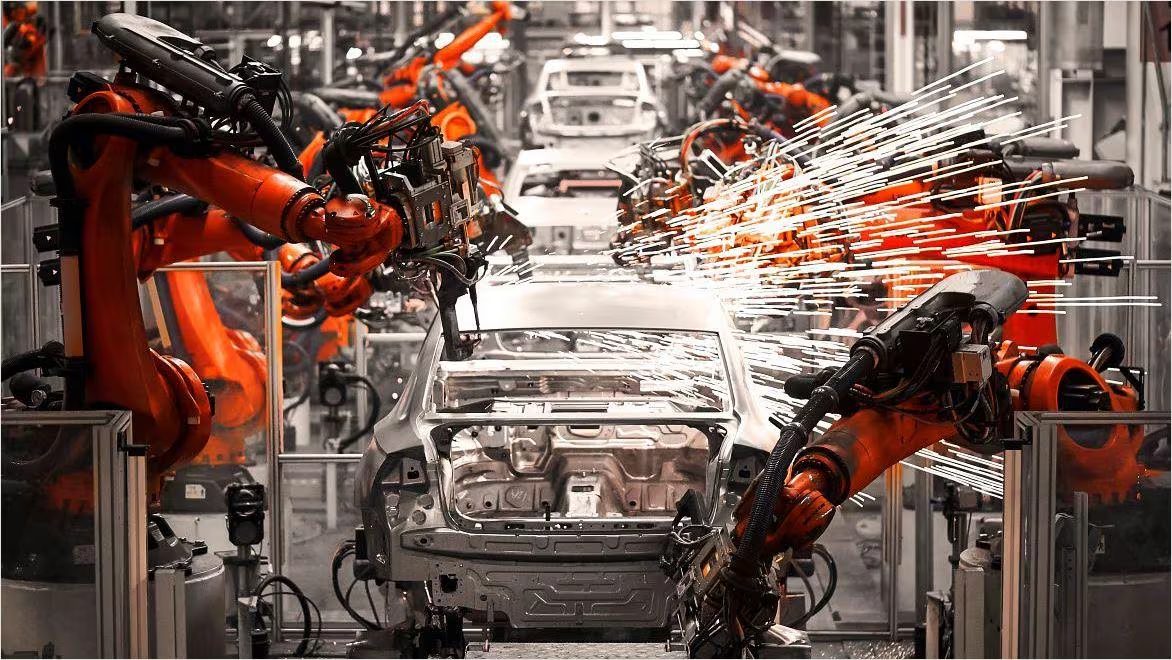

Unlocking Manufacturing Agility: How the Autodesk Product Design & Manufacturing Collection Drives Results

Discover how the Autodesk Product Design and Manufacturing Collection helps manufacturers overcome today’s challenges with integrated design-to-manufacturing workflows. Manufacturing today: Complex and demanding Manufacturing leaders face unprecedented complexity. Global supply chain disruptions, labor shortages, and sustainability mandates are reshaping the industry. At the same time, customers expect faster delivery of customized products without sacrificing quality.…

Design & Engineering

-

JIT Management in a Digital Manufacturing World

Explore how AI, IoT, and automation strengthen modern JIT management while addressing challenges related to supplier reliability and uncertain demand. As global supply chains become more interconnected, they become more fragile. In this context, successful just-in-time (JIT) strategies require more than traditional lean practices. They now need digital technologies capable of sensing, predicting, and adapting…

Production

-

Unlocking the Full Potential of PDMC: Why Adding Fusion to Your Manufacturing Workflow Is a Game-Changer

Boost efficiency, cut costs, and accelerate production by adding Autodesk Fusion to PDMC workflows for a fully connected design-to-manufacturing process. If you’re already using Autodesk’s Product Design and Manufacturing Collection (PDMC), you know the value of having a comprehensive suite of tools for design and engineering. But what if you could take that workflow even…

Industry Cloud for Manufacturing

-

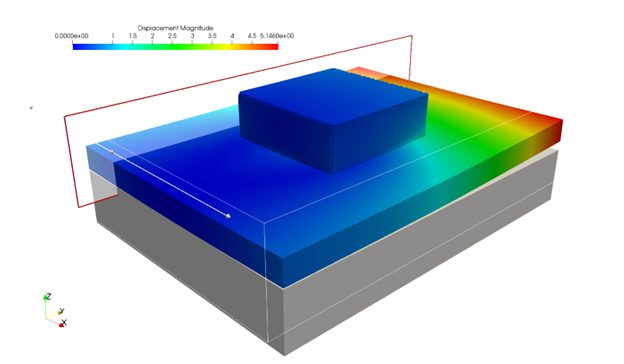

Validation of Multiscale DED for Netfabb simulation

Multiscale DED in Netfabb 2025.0 cuts steps ~2000× vs moving-source, runs in 8:34 with 5.0 GB RAM, and predicts distortion within 5.1% of scan. The challenge Until the 2025.0 release of Autodesk Netfabb Local Simulation, the only way to simulate the Directed Energy Deposition (DED) process was through detailed moving-source models. Moving-source models may be suitable…

Uncategorized

-

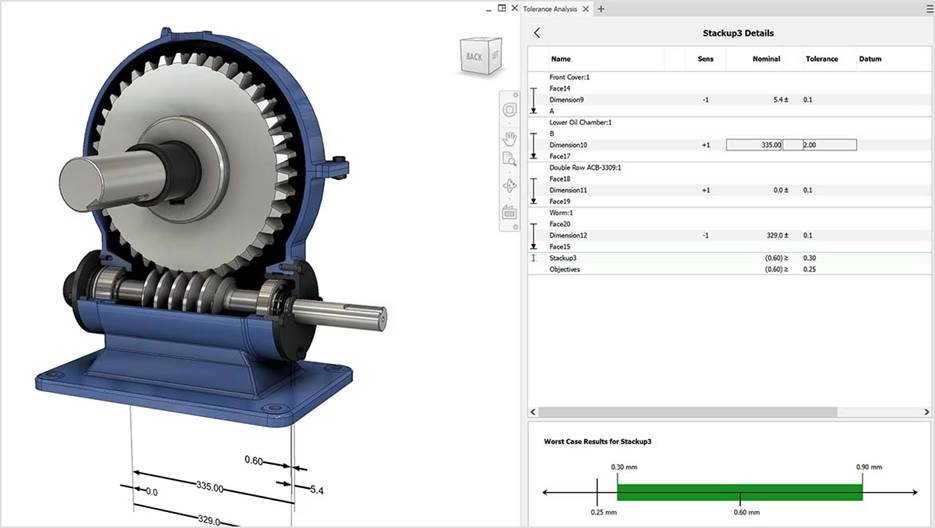

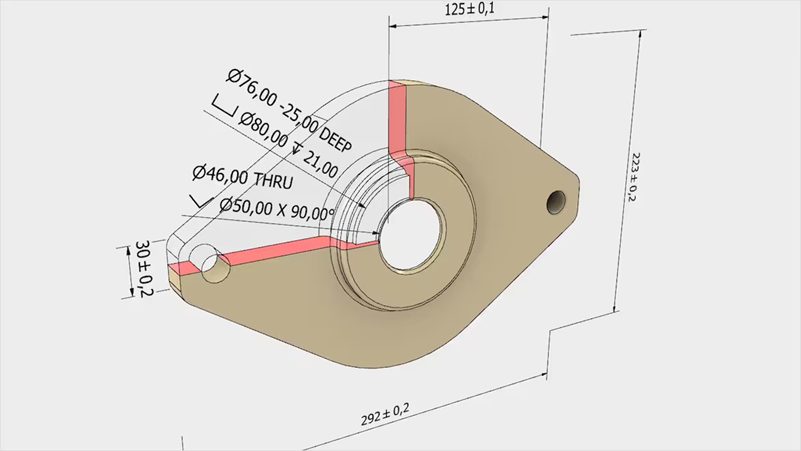

Complete Guide to GD&T Symbols: Geometric Dimensioning and Tolerancing

Discover the complete guide to GD&T symbols, their categories, standards, and practical applications across industries. Learn how Autodesk Inventor makes geometric dimensioning and tolerancing easier for beginners, improving design accuracy, manufacturing efficiency, and quality control. Modern manufacturing demands precision beyond basic dimensional tolerances. Engineers rely on GD&T symbols to communicate complex geometric requirements for critical…

Design & Engineering

-

Digital Simulation and Throughput Optimization with Autodesk

Digital simulation is one of the most powerful tools for helping manufacturers optimize factory throughput. Learn how simulation strengthens planning and how Autodesk FlexSim provides a powerful platform for modeling production behavior and reducing operational risk. Today’s factories contend with blistering timelines, variable demand, and increasing product complexity. With so much pressure on manufacturers, every…

Autodesk FlexSim

-

Driving Global Manufacturing Collaboration with Autodesk Fusion Manage: A Spirax Group Success Story

Discover how Spirax Group boosted global collaboration and efficiency with Autodesk Fusion Manage, the cloud PLM solution for modern manufacturing. At Spirax Group, innovation is at the heart of everything they do. With three niche businesses operating in the thermal energy and fluid path technology sectors, they design and manufacture industrial valves, pumps, and a…

Autodesk Fusion Manage

-

Understanding RTLS: The Role of Real-Time Location Systems in Manufacturing

Real time location systems for manufacturing provide real-time tracking and data integration in order to optimize asset utilization, inventory management, production efficiency, safety, and decision-making. This positions RTLS in manufacturing teams for data-driven success. RTLS for manufacturing In the fast-evolving world of manufacturing, staying competitive means constantly seeking ways to enhance efficiency, accuracy, and productivity.…

Data & Process

-

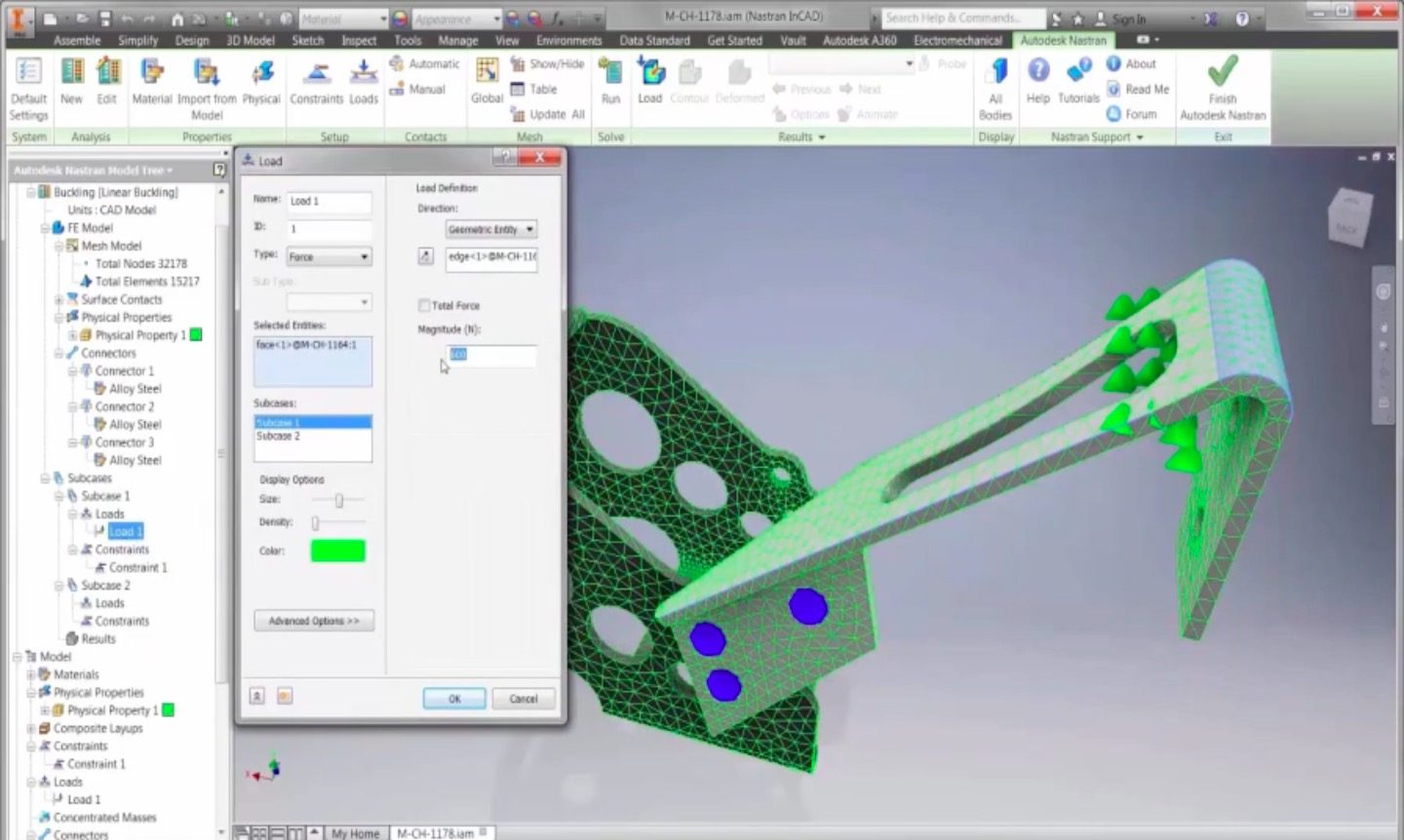

Introduction to Buckling Analysis: What Every Designer Should Know

This article introduces the principles of structural buckling, explains how instability arises under compressive loads, and explores linear versus nonlinear analysis methods. It then highlights how Autodesk Nastran enables detailed buckling simulations within the design workflow, helping engineers identify failure risks and improve performance before physical testing. Buckling is one of the most sudden and…

Design & Engineering

-

Autodesk Vault Connector What’s New for PDM and PLM Integration

The release of Vault 2026.1 brought the Autodesk Vault Connector, making it easier than ever to synchronize data between your product data management and product lifecycle management solutions. With the release of Vault 2026.2, we’ve added even more functionality using the Vault Connector—highlighted in this post. About the Autodesk Vault Connector First, a refresher if…

Data & Process