Explore how PLM enhances sustainable product design by improving data visibility, lifecycle assessments, and collaborative decision-making throughout the product lifecycle.

Sustainability is no longer a peripheral concern in product development. Environmental responsibility is now driving how engineers and designers approach everything, from material selection to end-of-life planning. As global regulations tighten and consumer expectations evolve, manufacturers are reevaluating the entire product lifecycle to uncover areas for improvement.

To support this shift, product lifecycle management (PLM) is allowing organizations to optimize product development processes with sustainability in mind. By offering greater visibility and control over data, PLM provides the infrastructure designers need to reduce waste, lower emissions, and design for circularity.

PLM as a catalyst for sustainability

Achieving sustainability in product design requires a holistic view of the product lifecycle.

Traditional engineering approaches often operate in silos, where design, manufacturing, and supply chain teams work independently. While there are benefits to specialization, the resultant fragmentation limits the ability of organizations to make sustainability-informed decisions at each stage. PLM platforms solve this issue by consolidating information and providing stakeholders with a unified data model. The idea being that centralization can facilitate early design decisions that reduce environmental impact, such as choosing low-impact materials, minimizing energy consumption during manufacturing, or designing components for easier disassembly and recycling.

Moreover, PLM supports lifecycle assessment (LCA) by providing traceable data on materials, suppliers, and manufacturing processes. With accurate and real-time information, engineers can simulate environmental impacts before committing to physical prototypes or production tooling. The ability to run “what-if” scenarios helps teams assess the sustainability trade-offs of various design options for a more informed and balanced decision-making process. Furthermore, the integration of supply chain data confirms that sourced components meet corporate sustainability targets regarding carbon footprint associated with logistics and procurement.

In the context of regulatory compliance, PLM helps products meet environmental regulations from the outset. For example, by embedding compliance checkpoints into workflows, PLM systems help mitigate the risk of costly redesigns or delays. PLM also maintains a historical record of design decisions and compliance documentation, which supports transparent reporting and continuous improvement.

Sustainable design with Autodesk Vault PLM

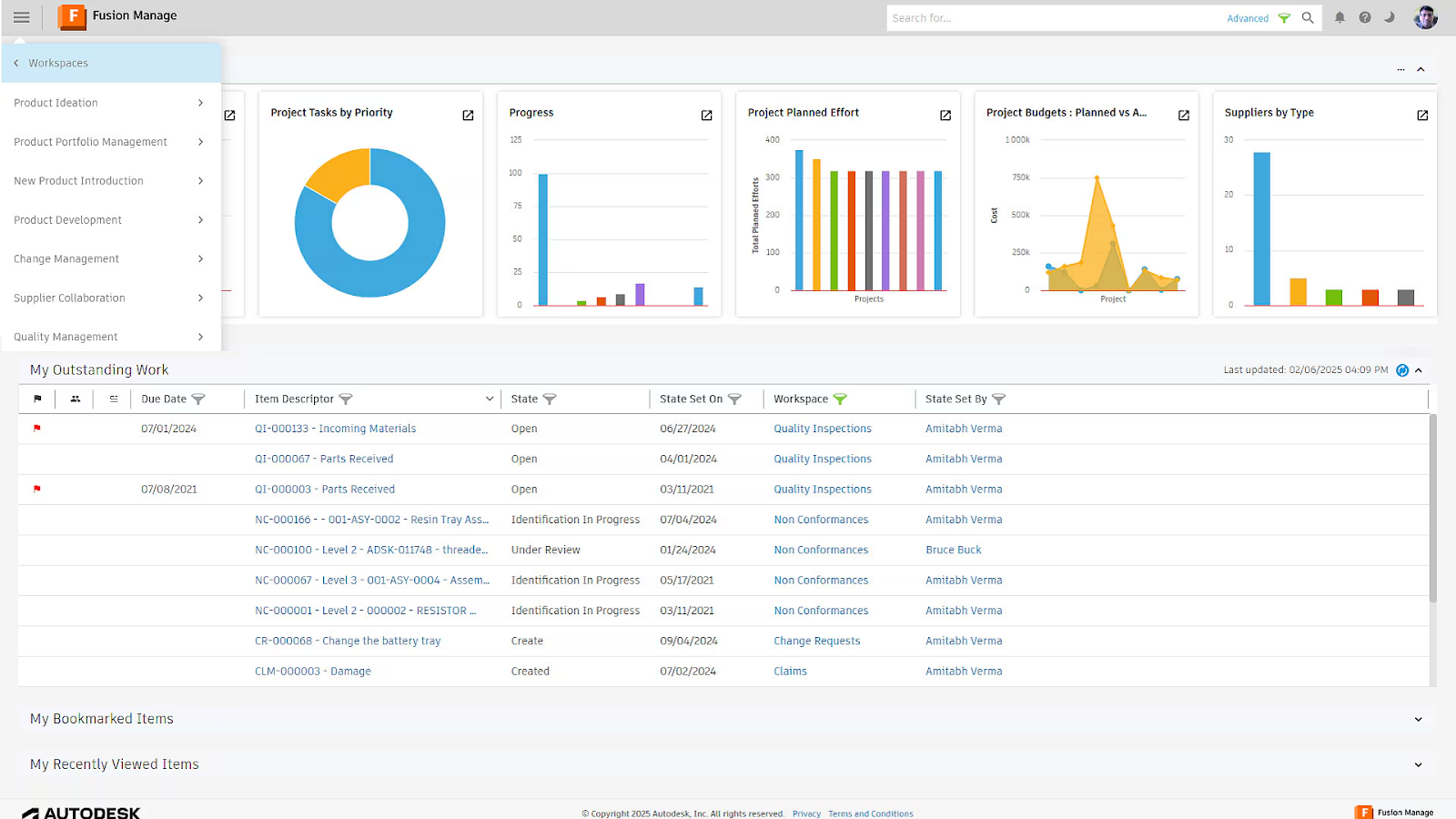

Autodesk Vault PLM is our solution to extend data management beyond engineering and into the full product lifecycle. With Vault PLM, cross-functional teams can collaborate efficiently while keeping environmental performance top of mind.

Optimize Data Management with Autodesk Vault

Secure, organize, and manage your engineering data efficiently.

Vault PLM integrates directly with CAD environments, meaning that design data remains tightly linked to the product record. With such a connection, early validation of sustainable design decisions is a breeze. For example, material choices made within the CAD model can be automatically reflected in the BOM and evaluated against sustainability criteria, including recyclability and embodied carbon. In this way, designers can immediately see the implications of using a particular alloy or polymer.

Vault PLM also streamlines change management processes so that product design updates are carefully controlled and fully traceable. Additionally, with automated workflows, organizations can feel confident that such changes are reviewed from both a performance and sustainability perspective with no unintended consequences appearing elsewhere in the product lifecycle.

Vault PLM facilitates supplier collaboration by making it easier to share specifications and collect compliance documentation. Suppliers can contribute directly to the product record, meaning your team gets improved transparency and alignment with environmental standards.

In addition, Vault PLM’s analytics tools allow organizations to measure and report on sustainability KPIs. Whether it’s tracking the proportion of recyclable materials used or the carbon footprint of sourced components, the system provides the data infrastructure demanded for environmental reporting. Ultimately, such insights improve an organization’s ability to meet external sustainability certifications and customer expectations.

Design with purpose

Sustainability in product design is a mandate, and PLM makes it possible through a centralized, data-rich environment. For those just getting started, Autodesk Vault PLM empowers organizations to embed sustainability into the heart of their product development strategy to move toward long-term environmental and business success.