Flexcon Helios, integrated with FlexSim, offers advanced simulation tools to optimize energy use, reduce costs, and lower emissions, supporting manufacturers in meeting environmental and operational goals.

The industrial sector contributes a significant share of carbon emissions and energy consumption. According to the World Economic Forum, global manufacturing accounts for 20% of global carbon emissions and consumes more than half of the world’s energy, making it clear that decarbonization and sustainability initiatives are an urgent priority.

As energy costs climb and pressure to meet sustainability goals increase from consumers, investors, and regulators alike, companies are facing a balancing act to reduce emissions and manage resources. At the same time, operations need to remain efficient and margins intact.

The ability to accurately simulate and optimize energy use is critical. Flexcon Helios, a FlexSim sustainability module developed by Flexcon, is now helping to solve this challenge. It optimizes energy efficiency and reduces costs by enabling facilities to analyze energy use and implement dynamic energy policies. When paired with CO2 intensity and cost data, it offers a comprehensive view of total factory expenses and carbon footprint.

Flexcon Helios enhances industrial energy planning by modeling to measure power needs, CO2 intensity, and dynamic pricing. It helps manufacturers manage and optimize machinery, factory layout, and energy sources to lower emissions and meet sustainability targets.

Benefits of FlexSim and Flexcon Helios

Energy accounting with Flexcon Helios in FlexSim helps manufacturers understand total system power demands to pinpoint efficiency opportunities. By analyzing both carbon output and costs, teams can evaluate the environmental and financial impact of operational strategies.

Detailed energy policy management defines power requirements for individual processes and systems to reflect realistic consumption patterns. Simulating both variable energy sources—including renewables and fluctuating grid input—enables more resilient planning. With predictive analytics and actionable insights, companies can optimize operations for sustainability and make data-driven decisions throughout the simulation process.

“Accurately simulating and optimizing energy use is essential in today’s manufacturing landscape,” says Matt Oosthuizen, Sustainable Manufacturing Specialist, Autodesk. “Flexcon Helios and FlexSim together empowers new modeling capabilities and visibility into power consumption, emissions, and costs, enabling data-driven decisions that improve efficiency and support sustainability goals.”

Take a closer look at Flexcon Helios

Flexcon Helios provides an opportunity for simulations and scenario planning in many different circumstances. Here are some examples of what you can do with Flexicon Helios!

- Predict When and Where Energy Is Used

Flexicon Helios enables granular energy forecasting across your production system — showing exactly when and where power is consumed, so you can optimize operations with precision.

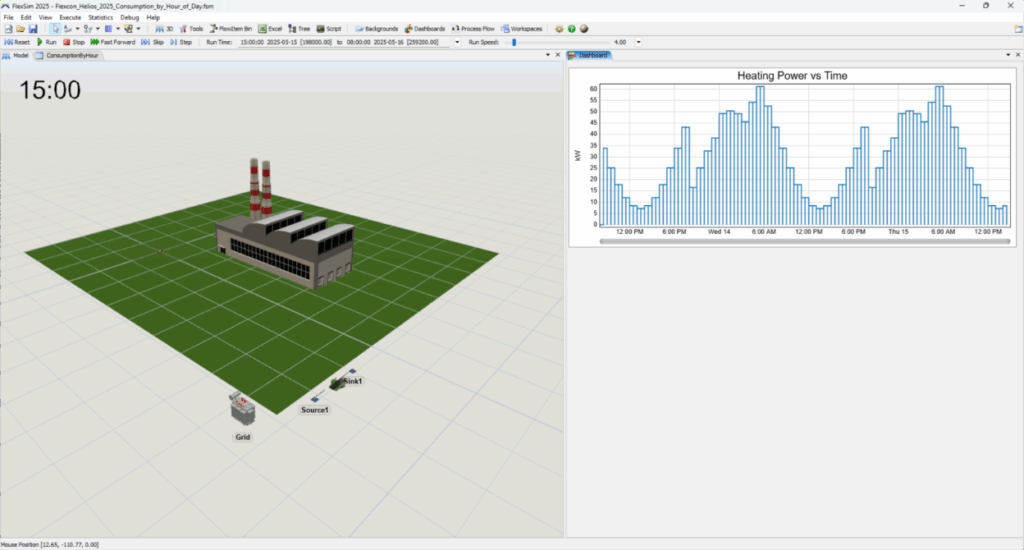

- Simulate Time-Based Energy Use

Analyze and calculate consumption daily, weekly, or seasonal profiles for energy use, like facility heating or air conditioning. Flexcon Helios helps you plan smarter around peaks, off-peak rates, or dynamic demand profiles.

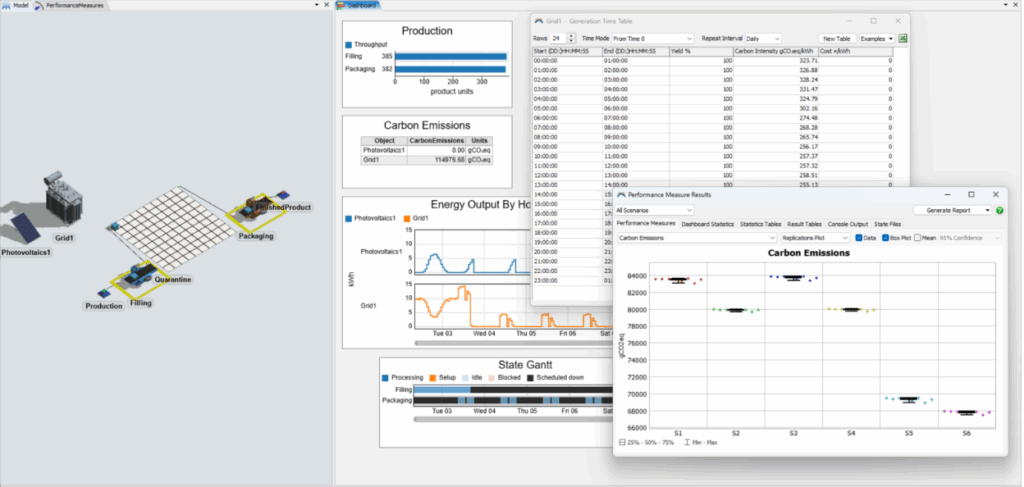

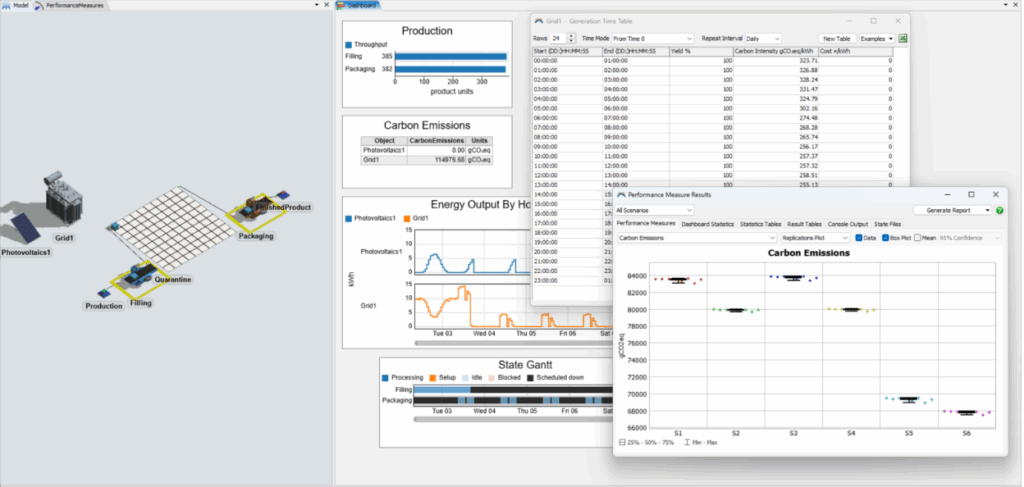

- Optimize Production Schedules for Minimal Carbon Emissions and Costs

Flexcon Helios can simulate the effect on energy consumption (costs and carbon emissions) from two factors: moving activities to a different location with a different energy mix, or performing them at a different time, when cheaper or greener energy is available.

See how changing production timing can dramatically reduce emissions and energy bills. Flexicon Helios evaluates multiple scheduling strategies to help you choose the most sustainable path.

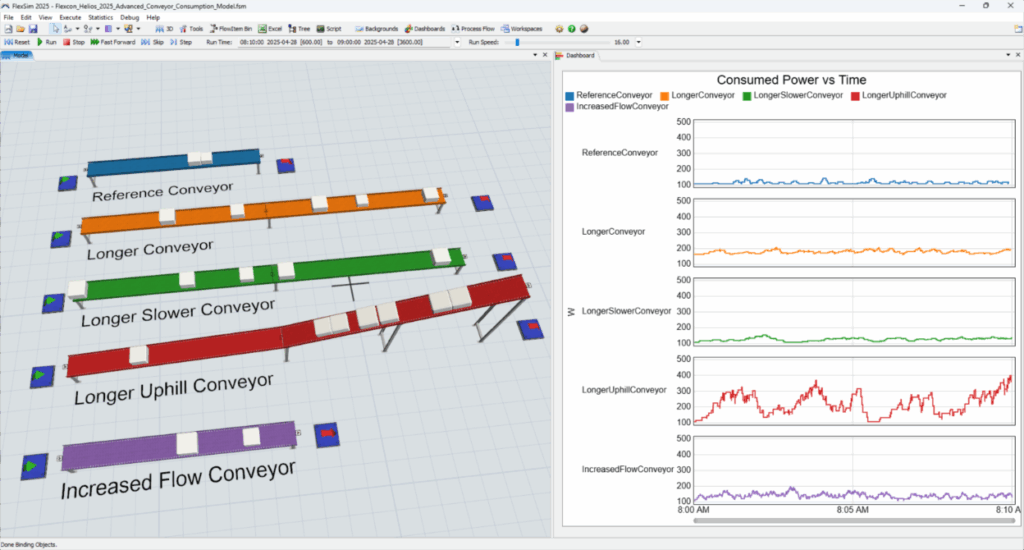

- Model Conveyor Power Demand with Real Physics

Flexcon Helios can be used to accurately simulate conveyor energy use using ISO 5048 formulas. It takes into account belt load, speed, slope, installation length, and various resistances, providing real-world insight into operational energy draw.

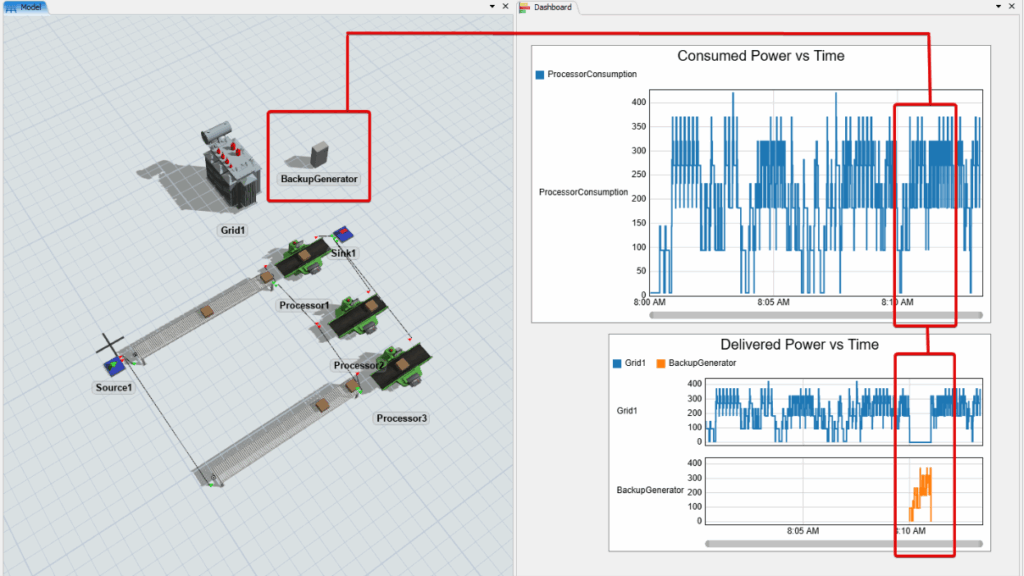

- Handle Energy Source Failures with Resilience

A FlexSim model allows users to explore scenarios where energy sources become unavailable. Flexcon Helios can simulate energy dispatch from backup systems and analyze system resiliency during grid power drops or when using intermittent renewable energy sources.

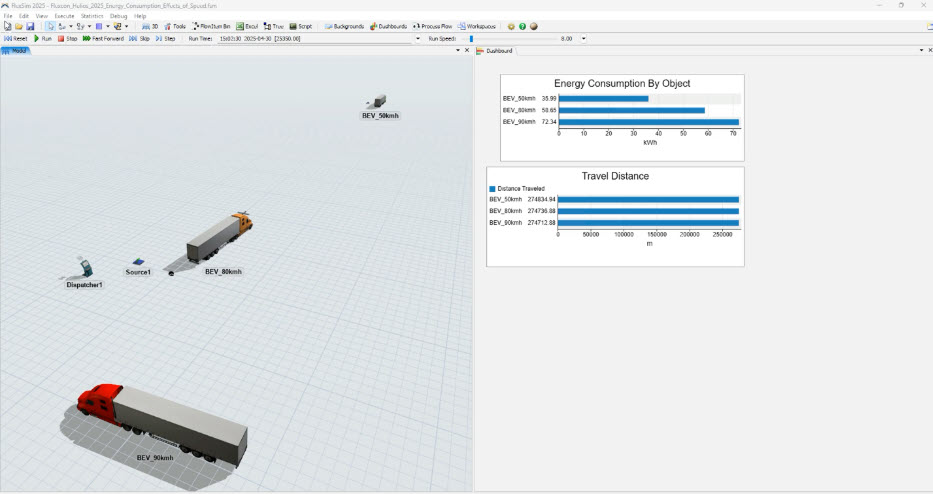

- Link Energy Consumption to Equipment Speed

Flexcon Helios can take into account the impact of vehicle and machinery speeds on energy consumption to find the optimal trade-off between business performance, costs, and carbon emissions.

Try Flexcon Helios today

Flexcon Helios is now available for download.