Data & Process

-

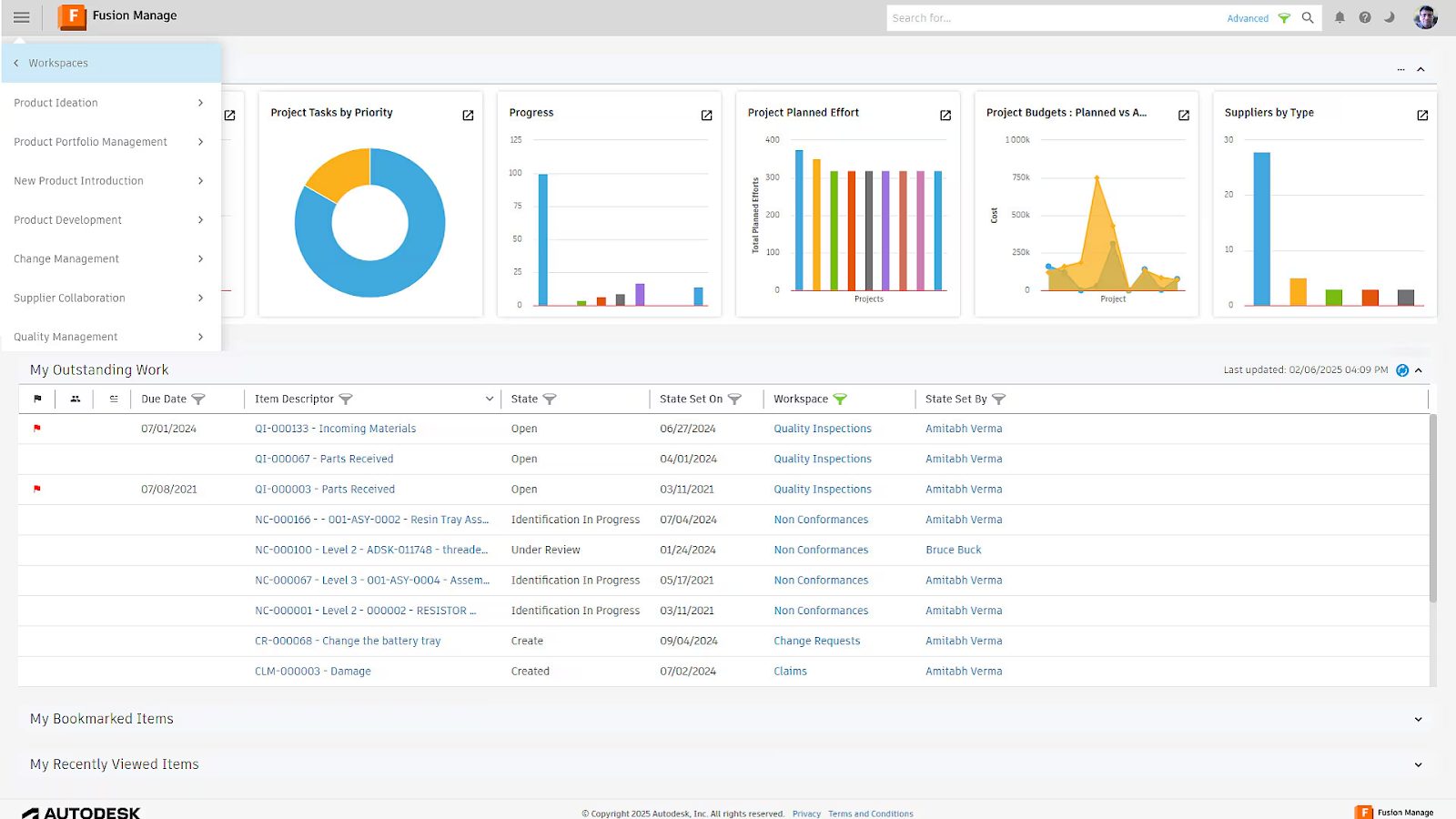

Eliminating System Silos to Enable Global Scale: ATL Technology’s Transformation with Fusion Manage

Discover how ATL Technology unified global design and manufacturing operations with Autodesk Fusion Manage, transforming fragmented systems into a centralized, scalable PLM platform. Operating across multiple continents, ATL Technology struggled with inconsistent systems, disconnected data, and uneven process maturity – creating serious roadblocks as the company grew. By adopting Autodesk Fusion Manage, the global medical…

Data & Process

-

Version Control in Manufacturing: Stop Designing on Outdated Data Before It Costs You Profit

Poor version control in manufacturing causes rework and missed deadlines. Discover how Autodesk Vault stops outdated data from draining profit. Engineering teams never intend to design from outdated data. Yet in shops that still rely on shared drives, email threads, and tribal file‑management habits, it happens every single day. What looks like a small annoyance…

Data & Process

-

Accelerate Time-to-Market and Reduce Risk: The Six Phases of NPI Explained

Learn how structured NPI processes cut time-to-market by up to 50%, improve quality, and enable cross-functional collaboration for manufacturing leaders. Why NPI matters New Product Introduction (NPI) is the structured process that transforms ideas into market-ready products. Companies that implement formal NPI frameworks achieve 30–50% faster time-to-market and 40% fewer post-launch quality issues compared to…

Design & Engineering

-

Unlocking Manufacturing Agility: How the Autodesk Product Design & Manufacturing Collection Drives Results

Discover how the Autodesk Product Design and Manufacturing Collection helps manufacturers overcome today’s challenges with integrated design-to-manufacturing workflows. Manufacturing today: Complex and demanding Manufacturing leaders face unprecedented complexity. Global supply chain disruptions, labor shortages, and sustainability mandates are reshaping the industry. At the same time, customers expect faster delivery of customized products without sacrificing quality.…

Design & Engineering

-

Unlocking the Full Potential of PDMC: Why Adding Fusion to Your Manufacturing Workflow Is a Game-Changer

Boost efficiency, cut costs, and accelerate production by adding Autodesk Fusion to PDMC workflows for a fully connected design-to-manufacturing process. If you’re already using Autodesk’s Product Design and Manufacturing Collection (PDMC), you know the value of having a comprehensive suite of tools for design and engineering. But what if you could take that workflow even…

Industry Cloud for Manufacturing

-

Driving Global Manufacturing Collaboration with Autodesk Fusion Manage: A Spirax Group Success Story

Discover how Spirax Group boosted global collaboration and efficiency with Autodesk Fusion Manage, the cloud PLM solution for modern manufacturing. At Spirax Group, innovation is at the heart of everything they do. With three niche businesses operating in the thermal energy and fluid path technology sectors, they design and manufacture industrial valves, pumps, and a…

Autodesk Fusion Manage

-

Understanding RTLS: The Role of Real-Time Location Systems in Manufacturing

Real time location systems for manufacturing provide real-time tracking and data integration in order to optimize asset utilization, inventory management, production efficiency, safety, and decision-making. This positions RTLS in manufacturing teams for data-driven success. RTLS for manufacturing In the fast-evolving world of manufacturing, staying competitive means constantly seeking ways to enhance efficiency, accuracy, and productivity.…

Data & Process

-

Autodesk Vault Connector What’s New for PDM and PLM Integration

The release of Vault 2026.1 brought the Autodesk Vault Connector, making it easier than ever to synchronize data between your product data management and product lifecycle management solutions. With the release of Vault 2026.2, we’ve added even more functionality using the Vault Connector—highlighted in this post. About the Autodesk Vault Connector First, a refresher if…

Data & Process

-

What’s New in Autodesk Vault 2026.2: Work Smarter, Move Faster

Autodesk Vault 2026.2 enhances PLM connectivity with Fusion Manage integration, streamlines data management, and boosts productivity with new sync and workflow features. Autodesk Vault 2026.2 brings seamless connectivity for Vault PLM users with the introduction of the integrated Fusion Manage panel in Vault. Vault 2026.2 also includes a set of targeted improvements designed to make…

Data & Process

-

Cloud Product Lifecycle Management for Distributed Product Teams

This article examines how cloud PLM solutions support distributed product teams by improving accessibility, collaboration, and scalability. It also highlights Autodesk’s cloud PLM tools (Fusion Manage and Vault PLM) and how they facilitate change management to improve supplier collaboration and connect teams across the full product lifecycle. The global design and manufacturing industry is more…

Data & Process

-

Ensuring EU MDR Compliance: The Crucial Role of Fusion Manage in Medical Device QMS

Learn how Fusion Manage helps medical device manufacturers meet EU MDR requirements with a flexible, cloud-based QMS that connects design, risk, and postmarket data for continuous traceability and global compliance. Modern medical device companies increasingly rely on quality management systems (QMS) to meet evolving regulatory demands like. In this post we’ll explore how cloud-based Autodesk Fusion Manage takes…

Data & Process