Last year was a tough period for a lot of folks, particularly in Southern California, which experienced devastating wildfires that destroyed around 19,000 structures, 16,000 of which were single-family homes.

Rebuilding efforts are well underway, and to learn more about how recovery is unfolding, I caught up with Ben Stapleton, Executive Director at USGBC California. In this episode, Ben discusses what it takes to rebuild after the wildfires, how climate change is reshaping our communities, and why action, education, and resilience matter now more than ever.

We discuss:

The scale of the 2025 wildfires in Southern California is still hard to fully process. Entire neighborhoods were impacted. Families were displaced. And the rebuilding journey ahead is long. Ben recalls that in the weeks after the fires, communities rallied and plans formed quickly. But that early momentum doesn't last forever.

“We're helping each other, and there's this high that comes from that. But then the action fades. People move on. We're in this dip right now, and the reality is it's going to take five or 10 years to rebuild from this,” he says.

Through his work on the LA County Blue Ribbon Commission, Ben saw just how complex recovery is. Still, one thing stood out. Access matters. Compared to other disasters, LA’s recovery moved faster because resources were available.

“We were already much further ahead of recovery than the folks who lived through the Lahaina fire in Maui. And that's simply because of access to resources and supply chain.”

That perspective shaped USGBC California’s response, and the team focused on educating and coordinating with key community members. They unified green building groups across the country and leaned on lessons from past fires.

This helped Ben and his team gather even more insights and set clear goals for recovery.

For example, Ben initially told his team that if they could help 20% of the roughly 16,000 destroyed homes be rebuilt in a more resilient and sustainable way, that would be meaningful progress. But those expectations quickly shifted.

“I talked to a gentleman who managed a lot of the recovery from the Marshall Fire out in Colorado, and he said that by educating the public and the contractors and by creating some availability incentives, they were able to get 80% of homes rebuilt to be all electric and more resilient and sustainable.”

Natural disasters like wildfires can feel completely out of our control. And while there are a lot of aspects that are out of our hands, there are things we can do to better prepare our homes and communities.

Simple steps like protecting vents, closing eaves, using more fire-resistant materials, and avoiding attached structures can reduce wildfire risk. A lot of these things aren’t difficult or expensive to do. The gap, says Ben, is in awareness and education.

And so, USGBC California stepped in to fill that gap, through efforts like:

“I found there was no one owning this space, and the education could do so much,” Ben remarks.

“We need to start taking more ownership as communities on how we care for each other and how to respond to a disaster. We’d like to think our first responders are the fire department and the police, but honestly, it's probably your neighbors. So, how are we lifting each other up in those events of disaster and putting the tools and infrastructure there to support that?”

Even when people want to rebuild greener and more resilient, cost can be the biggest barrier.

To this, Ben says that USGBC California set out to make rebuilding more affordable and accessible. Instead of leaving homeowners and contractors to navigate pricing on their own, the team created a shared marketplace designed to lower costs through scale.

“We white-labeled a platform by a company called Building Ease, and we created a rebuild marketplace,” Ben explains

When people in the same area need similar materials at roughly the same time, those purchases can be bundled. That gives manufacturers an incentive to compete on price.

“If people are going to purchase a hundred grates, they might get, say, a 25% discount. And you can see it as a neighbor and go, ‘Oh, there's a bunch of people here purchasing heat pumps. If I get on that, I can drop my cost by 15%.”

He continues, “We’re trying to get these things out there to see how we can do this a little bit differently.”

Rebuilding is always a challenge. For those dealing with the aftermath of the Southern California fires, those hurdles include the following.

Supply chain and logistics

Los Angeles already struggled to build housing before the fires. “The LA region built about 12,000 homes in the last decade,” Ben says. Now, communities are trying to rebuild roughly 16,000 homes in just a few years.

Developers feel the strain. “We need 20 to 50 more of us,” Ben recalls hearing from builders. “There’s no possible way we can build enough.”

Electrification costs and knowledge gaps

While all-electric homes can lower utility costs over time, upfront pricing can be steep.

“I’m hearing from people who are rebuilding that those costs are coming in 25 grand, 30 grand more,” Ben said.

The issue isn’t the technology. It’s execution. Many contractors don’t yet know how to design all-electric homes efficiently, including eliminating gas infrastructure altogether. Until that knowledge gap closes, costs stay higher than they need to be.

Landscape, fire risk, and competing priorities

Homes get most of the attention, but landscape matters just as much. Fire safety guidelines often call for bare zones around homes, especially within the first 5 feet.

“We can’t have no vegetation in entire areas of the city,” Ben said. Urban communities already face heat, biodiversity loss, and water challenges. The better path is smarter design, using native oaks, grasses, and shrubs that reduce fire risk while restoring ecosystems. “That’s the future,” Ben said. “And we could do that now.”

Insurance and labor pressures

Insurance may be the toughest challenge of all. Even when owners rebuild to the highest code standards, coverage isn’t guaranteed.

“You could rebuild your home, follow all the rules, and you still may not be insurable,” Ben explained. Insurers often assess risk at the community level, not the property level.

Layer on labor shortages and rising costs, and rebuilding becomes even harder. Without changes in how insurance, workforce, and education come together, these challenges will continue to slow recovery when communities need momentum most.

Digital Builder is hosted by me, Eric Thomas. Remember, new episodes of Digital Builder go live every week. Listen to the Digital Builder Podcast on:

or wherever you listen to podcasts.

As a construction project manager, a key part of your role is navigating change throughout the project. The ability to effectively handle shifts and curveballs is especially critical because project changes are, for the most part, inevitable.

Even the best-laid construction plans can shift, depending on what reality looks like in the field. And with ongoing material shortages and labor constraints, those changes can carry a higher risk than ever before.

The best project managers recognize this, and they know how to anticipate and absorb change without letting it derail budgets, schedules, or team trust.

Our recent webinar, From Chaos to Calm: Navigating Change in Construction Project Management, sheds light on practical steps you can take to manage project changes and how Autodesk Construction Cloud (ACC) can help.

Want to see how leading teams are turning constant change into a competitive advantage? Watch the full webinar on demand.

We mentioned this above, but it’s worth repeating: project changes are inevitable.

This is true across industries, but in construction, change is uniquely difficult to manage because projects are built in the real, physical world. There’s no undo button in the field. Unlike digital projects, which can typically be rolled back, construction projects require actual physical labor and materials.

Plus, there are various trades on site together, and when each trade’s work relies on another, a single change can ripple across schedules, scopes, and costs.

Then there are the ghosts of changes past. This is when past changes and decisions come back to haunt you in the form of a dispute.

One of the best ways to manage project changes effectively is to treat them as a holistic, connected workflow rather than a series of isolated change orders. When you connect the different components involved (people, information, approvals, etc), you can reduce blind spots and prevent small issues from snowballing.

You should also design for traceability. Make sure every decision has context (who/what/why) and is captured in your documentation. In doing so, you make decisions easy to find and defend in case of audits or disputes

Finally, standardize how teams log, route, and resolve changes. Standardization helps teams move faster and promotes consistency so everyone knows what to do, where to log changes, and how decisions get resolved.

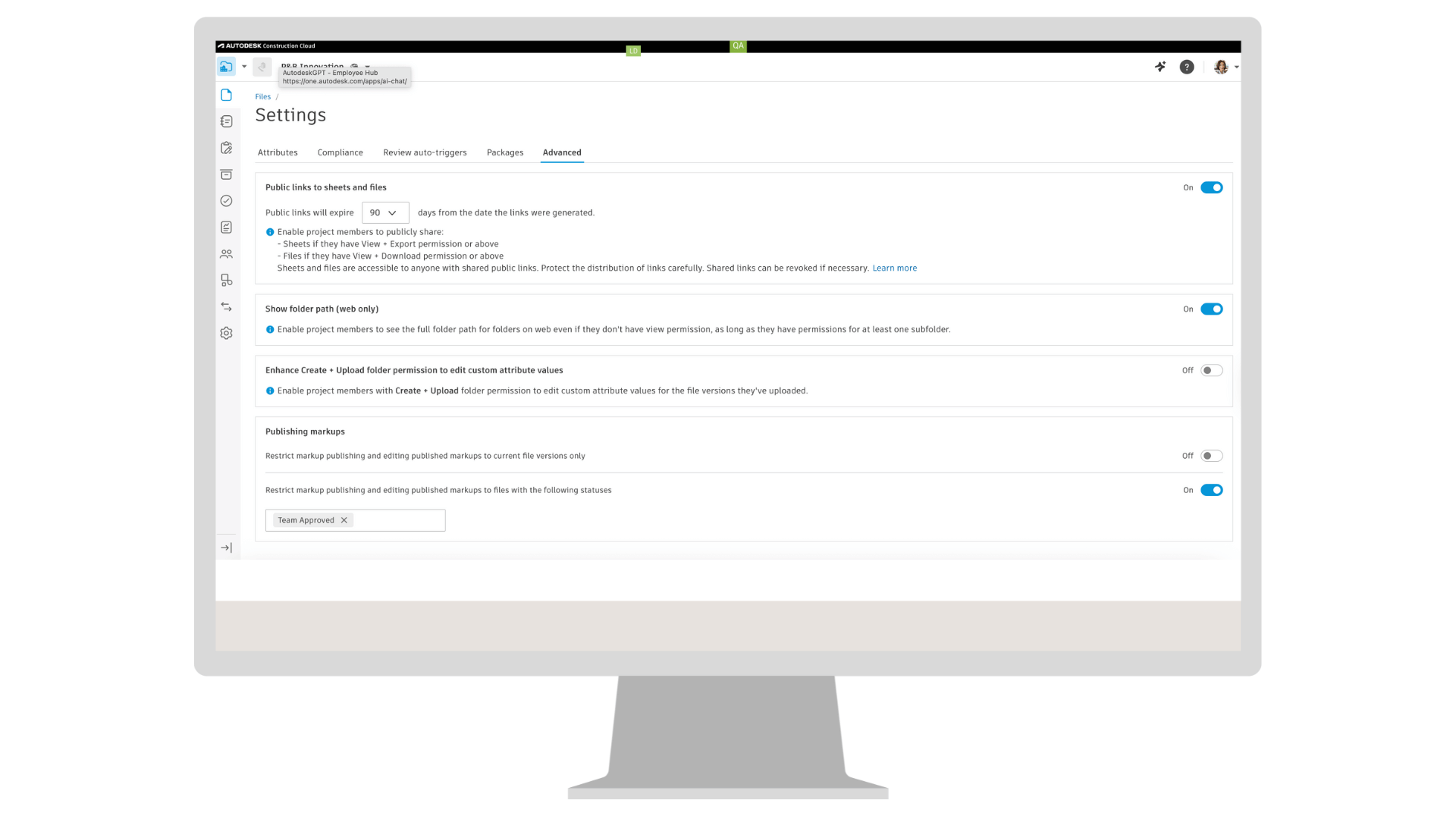

ACC brings all of this together by giving project teams a shared system to manage change as it happens, not after the fact. Instead of managing RFIs, submittals, correspondence, costs, and schedules across disconnected tools, ACC connects them in one place.When a change starts in the field, teams can document it immediately, attach supporting context, and route it through the right approvals without jumping between systems.

Issues identified can be easily marked and documented and escalated into an RFI. And if needed, can be used to initiate change orders. Potential change orders tie back to scope, cost, and schedule impacts. Communications are documented and actions tracked in an activity log, so there’s an audit trail along the way.

Stakeholders need to communicate in order to discuss changes and move the project forward. But when communication is scattered across different channels (email, phone, in-person conversations), details fall through the cracks and information becomes harder to track.

Decisions slow down, context is lost, and backup goes missing. These issues cause inefficiencies, and people spend time chasing answers instead of moving work forward.

Instead of using multiple methods and tools to communicate, move everything into a central, permissioned channel that’s tied back to the work. Not only does this keep everyone on the same page, it also makes it easy to link messages to relevant project information like files, issues, RFIs, and submittals.

Communication doesn’t happen in isolated email threads or phone calls. It should always tie back to the work happening on the project.

This way of working is far more efficient. Plus, it allows teams to have an audit trail for accountability and dispute resolution.

How does project comms come to life in Autodesk Construction Cloud? ACC’s Correspondence tools give teams a single place to document decisions and keep messages connected to the right project records.

Create and classify messages in one place, then generate downstream items (e.g., RFIs) directly from that thread. No retyping. No hunting for screenshots and email chains. You can also attach references, including emails, specs, photos, and issues, so approvers get the full context behind the decision they’re being asked to make.

Complex review chains, vague requests, and incomplete backup cause RFIs to stall, which then delays field progress. Teams end up going back and forth just to clarify what’s being asked. Meanwhile, crews wait.

Rather than starting RFIs from scratch, generate them from actual conversations to preserve context. You can also speed up decisions by including suggested answers, annotated files, locations, and known cost or schedule impacts.

Because ACC keeps communication tied to the work, connecting RFIs to messages happens naturally. You can create an RFI right from the Correspondence tool, and in the process, auto-link all related context. It’s also easy to route it to the right party with clear due dates.

Additionally, you can co-review the RFI with external stakeholders via email without losing the audit trail.

Changes are easier to deal with when you see them coming. You can do this in construction projects by capturing potential change orders (PCOs) early, and then connecting them to contracts, cost items, and the master schedule.

This process makes risk visible before it turns into a problem, ultimately protecting margins and keeping projects on track.

To stay ahead of risk, log PCOs the moment risk happens. You can initiate a PCO from other items like RFIs, submittals, and correspondence, creating a direct link for context. You should also aggregate all cost lines (GC, subs, suppliers) and attach the evidence (quotes, emails, photos), so approvals don’t stall due to missing information.

Also, be sure to update the schedule impact with reason codes and link it back to the PCO.

Cost Management and Schedule in ACC come together to help teams manage change. Since your cost and schedule workflows don't live in separate silos, you can deal with change orders early.

When a change comes up, you can open a potential change order directly from an RFI, submittal, or correspondence. That way, the change starts with context, and you’re not chasing emails or trying to piece the story together.

Schedule impacts follow the same path. Teams can record delays, document the reason behind them, and link those delays to the same change that’s driving the cost impact. Instead of tracking schedule slips in one place and dollars in another, everything stays connected.

If you’re a project manager who’s had to gather monthly reports for execs, you know how chaotic the process can be.

Finding and organizing project data can be time-consuming, and it gets even harder when you’re constantly getting pulled into day-to-day fire drills. You start a report, something urgent pops up, and when you come back, you’re trying to remember where you left off.

Instead of spreadsheets that you need to update manually, use connected dashboards and reports that are built from PCO logs, budgets, RFIs, and schedules. For best results, leverage project templates and permissions to standardize setup across small and large projects.

Plan for closeout on day one by making sure as-builts and O&Ms are exported with the decisions, changes, and references already linked.

The Reports, Templates, and Closeout tools in Autodesk Construction Cloud take the scramble out of reporting and turn it into a repeatable process.

Using templates, teams can spin up projects quickly with consistent folder structures, naming conventions, and approval workflows.

From there, real-time reports pull directly from live project data, showing outstanding changes, approval status, and forecast impacts without manual updates. Leaders get visibility into risk as it develops, not weeks later.

When it’s time to close out a project, ACC makes it easy to export complete as-built packages that include RFIs, submittals, files, and activity logs. Everything stays connected, searchable, and ready for turnover or future reference.

PENTA shows us a great example of how to navigate change in a high-stakes project. As the GC for the Las Vegas Grand Prix, PENTA was responsible for delivering the race track, along with the pit building, grandstands, and supporting infrastructure.

It was a high-pressure project involving about 500 people. And with less than one year of construction, there was no margin for delays or missteps.

The project moved fast, and change was constant. Midway through construction, the team introduced a major shift by adding an underground tunnel after part of the pit building was already complete. PENTA had to pivot immediately. Design teams updated documents. Trade partners regrouped. Schedule and material impacts were assessed in real time.

Using Autodesk Construction Cloud, PENTA kept information flowing and teams aligned. They could review design changes side by side, assess schedule impacts, and view material availability without slowing the project. Because documentation stayed current and accessible, the team could make informed decisions in real time instead of reacting after the fact.

With accurate, up-to-date documentation and connected workflows, PENTA stayed focused on what mattered most: keeping the project moving and delivering on time.

Successful project managers don’t avoid change. They manage it better by staying organized, planning ahead, and ensuring that teams, messages, context, and decisions are always connected. Want to see these workflows in action? Watch the on-demand webinar From Chaos to Calm: Navigating Change in Construction Project Management.

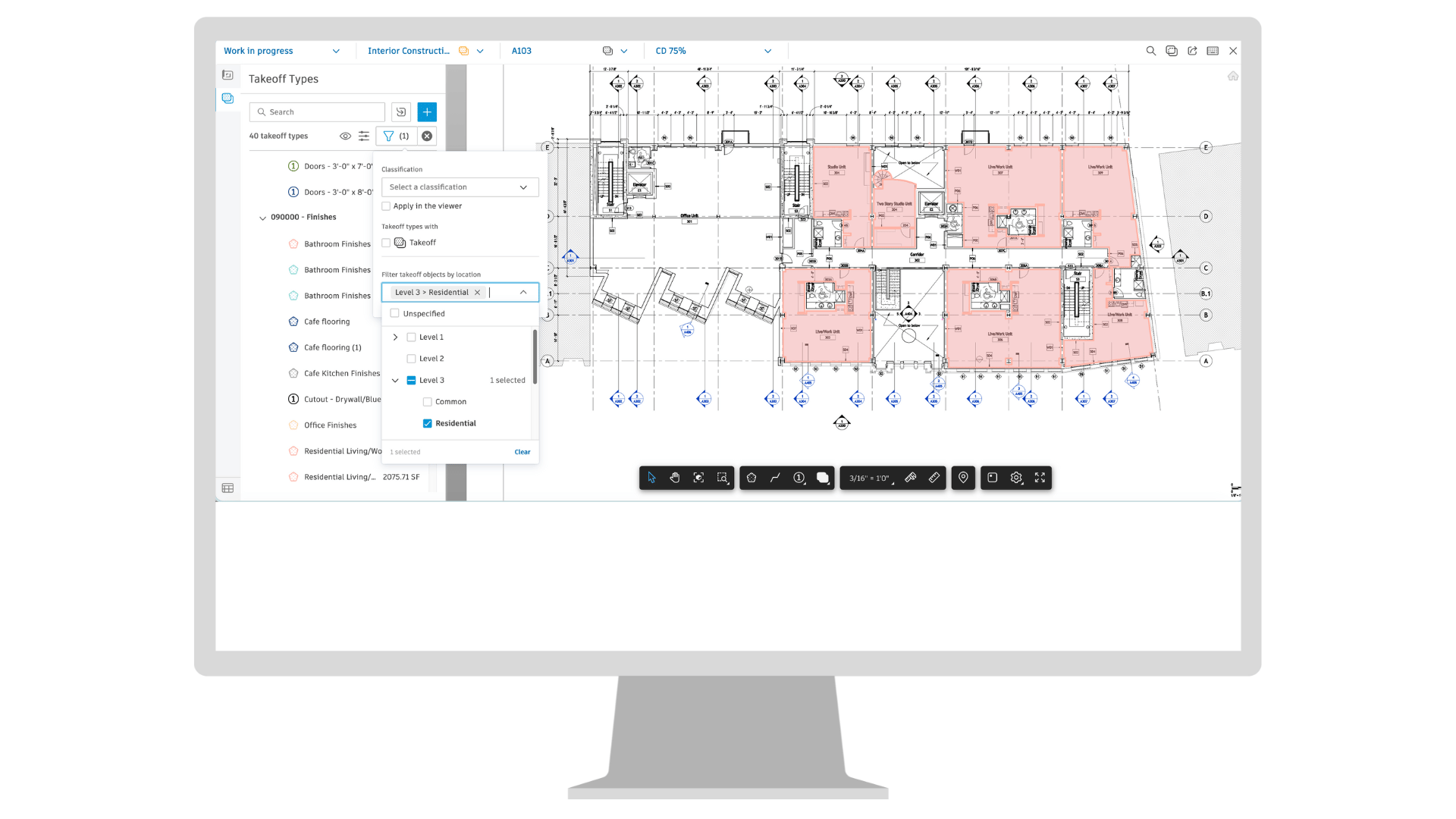

Estimators have always been a crucial part of the construction process, and today, their role isn’t just expanding — it’s evolving.

Estimators today are navigating one of the most demanding roles in construction. Between tight deadlines, constant price fluctuations, and increasingly complex workflows, estimators are expected to deliver accurate answers quickly and with very little margin for error.

The expectations placed on construction estimating teams have never been higher: tighter collaboration, higher data fluency, and more influence over design and project outcomes.

These days, if you’re an estimator, you’re not just taking costs; you’re also becoming one of the most strategic advisors on the project.

The role of the estimator is evolving because the construction industry and market are changing fast. Owners and internal teams have higher expectations, and technology is reshaping how work gets planned, priced, and delivered. And if you layer in issues like fluctuating costs, labor shortages, and tighter bid windows, the pressure is higher than ever.

Traditional estimating workflows that involve manual takeoffs, spreadsheets, and disconnected tools can’t keep up with today’s complexity.

As a result, teams increasingly rely on estimators not just to calculate costs, but to help shape decisions that determine whether a project moves forward at all. Modern estimators are stepping into a more integrated role across design, preconstruction, and operations. Not only that, but their role has a direct impact on risk, scope, and profitability.

For a long time, estimators were traditionally responsible for calculating the total costs of a project before the work began. And while that is still very much true today, that is not the only thing estimators are expected to do.

These days, estimators aren’t just calculators — they’re a hub of insight. They need to be able to advise on cost risk, schedule implications, constructability, and procurement strategies. They can also work alongside PMs, VDC, executives, and owners to influence design iterations, guide material choices, and align on scope.

As such, the estimator’s role now extends well beyond bid day and into the decisions that shape how a project is planned and delivered.

So, what do estimators need to thrive and succeed in today’s construction landscape? Some of the growing expectations include:

Estimators need to be tech-savvy enough to jump between 2D PDFs and 3D models within a single connected workflow. Fluency in data and analytics is also a must. This means being able to use dashboards and visualization tools to spot trends, track changes, and share insights with the broader team.

Estimators must go beyond line-item pricing and use historical cost data to guide early decisions. The ability to recognize patterns and compare similar projects will come in handy, as they’re expected to flag risk and provide more informed guidance during preconstruction.

Strong collaboration skills are needed in various roles, but they’re especially important for today’s estimators. They work closely with design teams, VDC, project managers, and owners to align budget and scope early. That means translating numbers into clear tradeoffs and helping teams understand how design decisions affect the bottom line. Strong communication keeps everyone moving in the same direction.

With prices shifting and bid timelines tightening, estimators need to adjust quickly. They might need to respond to last-minute changes, updated drawings, and evolving scopes while still maintaining accuracy. The ability to stay organized, recalibrate assumptions, and keep projects moving forward is now a core part of the role.

Another force driving change in estimating right now? Artificial intelligence in construction.

With AI capabilities becoming more embedded in the tools teams use, estimators can level up their workflows. Some of the benefits the estimators will start to see in the near future include:

Notice how none of the above points suggest AI is here to replace estimators. That's the bigger story here. AI is not replacing estimators. Rather, it strengthens their ability to focus on strategy, judgment, and collaboration.

The next era of estimating will blur the lines between design and preconstruction. AI-driven tools are already making it possible to see real-time cost feedback as designs evolve, which gives estimators a stronger voice earlier in the process. Instead of reacting to finished drawings, they can weigh in while ideas are still being shaped.

As platforms bring together estimating, takeoff, bid management, and prequalification data, insights become more connected and far more useful. Estimators will help teams compare design alternatives, evaluate sustainability tradeoffs, and understand schedule impacts before decisions are locked in.

Generative design, real-time cost modeling, and agent-based tools will shorten the path from concept to pricing and open the door to smarter, faster collaboration between estimators, architects, and engineers.

Have you tried Autodesk Estimate? Learn more.

We’ve all heard the saying that it’s better to show and not just tell. This is becoming increasingly evident in estimating. Owners today expect clear, visual communication to understand where their money is going and what their options look like. This can come in the form of dashboards, graphs, 3D-linked cost views, and scenario comparisons.

Using visuals to convey cost drivers, risk exposure, and tradeoffs strengthens trust with owners and makes estimates far more digestible. Beyond that, visualization accelerates alignment across stakeholders, aiding decision-making and reducing misinterpretation.

All of that ultimately leads to faster approvals and fewer surprises, which keeps projects moving forward with more confidence and less friction.

In order to stay competitive and protect margins, contractors must invest in the right mix of technology, talent, and process. Here are the investments to prioritize now and in the near future.

The role of the estimator is changing, and contractors who recognize that shift will have an edge.

Now, gaining that edge isn't just about equipping your teams with new tools (though that's part of it). Beyond that, you must also rethink how estimators fit into the broader project lifecycle.

If you want estimating to drive smarter decisions and stronger margins, start with a few practical moves:

The estimator of the future isn’t defined by how fast they can count quantities. They’re defined by how well they interpret data, influence design, guide teams, and use technology to drive smarter decisions. Contractors who invest in modern estimating tools, AI-driven insights, and visualization will position their teams to win more work, reduce risk, and move into the next era of preconstruction with confidence.

Invest today, starting with the Autodesk Preconstruction Bundle.

Across construction teams today, many planning workflows are still only somewhat digital. Schedules and lookaheads often live in Excel or other disconnected tools, requiring duplicate entry and manual updates that slow teams down and introduce risk.

Thankfully Autodesk Build has been helping building teams close that gap by connecting long‑term schedule strategy with short‑term field execution, all within Autodesk Construction Cloud (ACC).

But we often get asked about the difference between Schedules and Workplans. Let’s explore the critical differences between these capabilities and learn how to leverage them effectively for your projects.

Learn more in our on-demand webinar: Build with Confidence: Smarter Short-Term Planning with Workplan

In Autodesk Build, the Schedule represents the project’s strategic, long‑term plan. This is your CPM‑based master timeline—the backbone of the job. Built in specialist tools such as Primavera P6, Microsoft Project, or Asta Powerproject, the schedule captures project logic, dependencies, milestones, and the critical path. Schedules are often long and prone to change, so sharing them out with project teams and keeping project teams updated on changes can be difficult when they are built in these siloed scheduling tools.

Once published to ACC, the schedule becomes a read‑only single source of truth for the entire team to refer to and comment on. That read‑only posture is intentional. By protecting the baseline, teams can run reliable forecasts, perform change analysis, and make informed, strategic decisions without undermining schedule integrity.

Projects change, and any changes made to the master schedule can be easily shared by reuploading the latest schedule version, with version history documented.

The schedule focuses on the what and when at scale:

What it does not attempt to capture is equally important as what it does. Schedules are deliberately high level when it comes to resources. For instance, you dont use the schedule to assign tasks or track daily commitments. Instead, it provides the authoritative plan that feeds downstream execution.

That downstream execution happens in Workplans. Workplans in Autodesk Build are the tactical layer that converts schedule intent into reliable, short‑term delivery. They’re designed for weekly workplanning and multi‑week lookahead which define what the team will actually commit to in the near term.

Workplans can be directly connected to the master schedule to preserve end‑to‑end traceability, or created standalone when trade‑led coordination is needed. Either way, they’re collaborative, field‑ready, and execution focused.

With Workplans, teams can:

This trade‑level ownership removes ambiguity at handoffs and makes daily execution visible and measurable across the project team.

One of the most powerful aspects of Workplans is formal commitment tracking. When assignees commit to plan dates, those promises are locked for measurement. If a committed task needs to be replanned, a reason must be recorded. This creates an auditable trail that turns planning conversations into actionable data.

Workplans also bring constraints and blockers directly into the workflow. To keep planning proactive versus reactive, teams can capture roadblocks with photos or files, assign accountability, escalate issues to RFIs when needed, and track them through resolution.

All of this feeds a continuous improvement loop. Metrics like Percent Plan Complete (PPC), task status rollups, and root cause analysis help teams understand performance, coach behaviors, reduce rework, and improve predictability each week.

In simple terms:

Together, they connect strategy to execution, digitize planning workflows, and operationalize the master schedule into predictable delivery — all within one tool.

Learn more in our on-demand webinar: Build with Confidence: Smarter Short-Term Planning with Workplan

Construction projects involve multiple phases, stakeholders, and moving parts, which is why it’s so important to have documentation around when and how a contractor is paid throughout a project. Contractor payment schedules play a critical role here, as they outline the timing, structure, and conditions for each payment so everyone knows what to expect.

In this guide, we’ll go over everything you need to know about contractor payment schedules, including how they work, why they matter, and best practices for managing them.

Table of contents:

A contractor payment schedule is a written plan that outlines when and how payments will be made throughout a construction project. It typically ties payments to specific milestones, percentages of completion, or set time intervals. A clear payment schedule helps manage cash flow, reduce misunderstandings, and keep the project moving forward without financial surprises.

Construction projects involve both upfront payments and ongoing costs. A contractor payment schedule helps teams manage all of that by outlining exactly when payments are due, how much will be paid, and what must be completed before funds are released.

Consider the following:

Construction runs on cash flow. Materials need to be ordered, crews need to be paid, and equipment needs to stay on site. A structured payment schedule ensures contractors receive funds at predictable intervals tied to progress. That consistency helps avoid slowdowns caused by cash shortages and keeps work moving without unnecessary financial stress.

Payment disagreements often stem from unclear terms. When a schedule clearly defines milestones, amounts, and approval requirements, there’s less room for confusion. Everyone understands what triggers payment and what documentation is required. Clear agreements upfront reduce finger-pointing later and make it easier to resolve issues quickly if questions come up.

Without structure, costs can spiral. A payment schedule ties spending to actual progress, making it easier to track how much of the budget has been committed and how much remains. This visibility helps owners and contractors spot overruns early and adjust before small issues turn into major financial problems.

With a good contractor payment schedule, teams know what they need to deliver to get paid, and owners know when to expect construction invoices. That clarity builds trust and keeps communication focused on results rather than chasing paperwork or wondering when money will change hands.

Predictable payments support predictable progress. When funds are released in alignment with milestones, teams can plan labor, materials, and timelines with greater confidence. The result is fewer surprises, smoother coordination, and a project that stays closer to its original schedule and financial plan.

A strong payment schedule does more than list due dates. It clearly defines how money moves, what triggers payment, and how changes are handled.

Payment structure (timing and method) – Define whether payments follow a milestone, percentage of completion, or time-based model. Clarify how funds will be delivered, such as ACH, check, or wire. When timing and method are spelled out, there’s less guesswork and fewer delays tied to logistics.

Milestones or criteria tied to payments – Tie each payment to specific, measurable outcomes. This could include completing foundation work, passing inspections, or reaching a defined percentage of progress.

Documentation requirements – Outline what must be submitted before payment is approved. This may include invoices, lien waivers, inspection reports, or updated progress schedules.

Retainage details – If retainage applies, specify the percentage withheld and when it will be released. Note whether partial retainage can be reduced at certain milestones. Transparency around retainage prevents confusion at project closeout.

Payment terms – State the number of days for payment after invoice approval, such as net 15 or net 30. Clarify any late payment penalties or interest terms. Defined terms help manage expectations and protect both parties.

Change order process – Explain how scope changes affect payment. Document how change orders are priced, approved, and added to the schedule. A clear process ensures extra work gets paid for without disrupting the broader payment plan.

Schedule of values (when applicable) – For larger projects, include a detailed breakdown of costs by line item. The schedule of values helps track progress against the budget and supports accurate progress billing throughout the project.

Approval workflow – Identify who reviews and approves payment applications. Map out the steps from submission to release of funds. A defined workflow reduces bottlenecks and keeps payments aligned with project timelines.

Unlike standard invoices, construction payment schedules are tied to progress, performance, and formal approvals, not just services rendered. Construction payment schedules are more complex due to: gener

| Construction payment schedules | General invoicing | |

| Basis for payment | Tied to project milestones, progress, inspections, and formal approvals | Based on goods delivered or services rendered |

| Project timeline | Structured around long, phased timelines that may span months or years | Typically short-term or one-time billing cycles |

| Stakeholders involved | Involves owners, GCs, subcontractors, lenders, and inspectors | Usually between two parties: vendor and client |

| Approval process | Often requires inspections, sign-offs, and compliance checks before payment | Limited approval process; invoice review is usually sufficient |

| Retainage | A percentage may be withheld until substantial or final completion | Retainage is rarely used |

| Documentation | Requires lien waivers, progress reports, schedules, and compliance documents | Generally requires only an invoice and basic supporting details |

| Progress tracking | Payments depend on verified completion percentages or deliverables | Payment is not typically tied to ongoing performance tracking |

Not all projects are built the same, and payment structures should reflect that. Here are the most common contractor payment schedule types.

With this model, payment is issued only after the full scope of work is completed. It is simple and easy to understand, but it places the financial burden on the contractor until the job wraps up. This approach works best for small, clearly defined projects where timelines are short and the risk of scope changes is low.

A portion of the total contract value is paid upfront, with the remaining balance due at completion. The deposit helps contractors cover initial materials and labor costs, while the final payment ensures the project is finished as agreed. This structure is common in residential construction and smaller commercial projects.

Payments are tied to clearly defined stages, such as completing the foundation, framing, or rough-ins. Each milestone triggers a scheduled payment. This structure creates transparency, keeps projects accountable, and allows both parties to track progress in a straightforward way.

Progress payments are based on the percentage of work completed. Contractors typically submit documentation through a Schedule of Values or standardized forms. This approach supports steady cash flow and works well for long-term or complex projects where work unfolds in phases over time.

Under a retainage structure, a small percentage of each payment, usually 5 to 10 percent, is withheld until substantial or final completion. This protects the client by providing an incentive to finish the project properly. Contractors need to plan carefully, as retained funds can impact short-term cash flow.

Time-based payments compensate contractors based on hours worked over a set billing cycle, such as weekly or monthly. Materials may be billed separately. This model works well for projects with evolving scopes or time and materials contracts where flexibility is important.

Even the best payment schedule can run into friction if expectations are not clearly managed from the start.

Milestones can become gray areas if completion criteria are vague. One party may believe the work is done, while the other sees unfinished details. Without clearly defined standards or inspection checkpoints, disagreements can stall payment and strain working relationships.

If the scope lacks detail, it becomes difficult to tie payments to specific outcomes. Broad descriptions like “site prep complete” leave room for interpretation. Clear, measurable deliverables reduce confusion and make it easier to validate when payment is earned.

Construction payments often require supporting paperwork. When lien waivers, receipts, or progress reports are missing or delayed, payments get held up. Administrative gaps can slow down cash flow, even if the physical work is complete.

While retainage protects project owners, it can create pressure for contractors. With a portion of each payment withheld, contractors must cover labor and material costs without full compensation until closeout. Poor planning around retainage can create financial strain late in the project.

Payment applications often pass through multiple reviewers. If one approver is unavailable or slow to respond, funds may be delayed. Without a defined workflow and clear timelines, approval cycles can drag out longer than expected.

Unplanned changes can disrupt even the most organized payment schedule. When scope expands without formal change orders, payment timing and amounts no longer align with actual work. Clear change management processes help keep the schedule and budget on track.

A strong payment schedule does not happen by accident. It takes structure, clarity, and ongoing oversight.

Tie payments to specific, verifiable outcomes. Instead of vague milestones, define clear benchmarks such as passing inspection, completing framing, or reaching a set percentage of work. Measurable criteria reduce ambiguity and make it easier for everyone to agree when payment is earned.

Keep detailed records from day one. Store signed change orders, labor reports, material receipts, and inspection results in one place. Good documentation protects both parties and speeds up payment approvals when questions arise.

Use consistent templates for payment schedules, invoices, and supporting documents. Standardization reduces errors, saves time, and ensures every project follows a predictable structure. It also makes it easier to onboard new team members and subcontractors.

Manual tracking can slow things down. Construction management and accounting tools help automate progress tracking, document collection, and approval workflows. Digital systems provide real-time visibility into what has been billed, approved, and paid.

Discuss payment expectations early and revisit them regularly. Share updates on progress, flag potential delays, and confirm when milestones are approaching. Clear communication builds trust and prevents payment surprises.

Projects rarely go exactly as planned. If timelines shift or scope changes, revisit the payment schedule. Updating it to reflect current conditions helps keep cash flow aligned with reality and reduces friction later in the project.

When payment expectations are clear from the start, projects run smoother and relationships stay stronger.

A defined payment schedule creates consistency. Contractors can forecast incoming revenue, plan payroll, and purchase materials with confidence. Owners also gain visibility into when funds will be required. Predictable cash flow reduces financial stress and helps keep the project moving without unexpected slowdowns.

Clear milestones and payment terms leave less room for misunderstanding. When everyone knows what triggers payment and what documentation is required, disagreements decrease. That clarity helps prevent stalled approvals and keeps the project timeline intact.

Transparency builds credibility. When payments are issued according to a documented plan, trust grows between owners, contractors, and subcontractors. Reliable payment practices strengthen long-term working relationships and make future collaboration easier.

Structured schedules streamline billing and approvals. Teams spend less time chasing paperwork or clarifying payment terms. With standardized processes in place, finance and project managers can focus on execution rather than resolving avoidable payment issues.

Aligned payments support aligned progress. When funds flow in step with completed work, teams can maintain momentum and avoid costly disruptions. Over time, disciplined payment practices contribute to stronger margins and more stable operations.

The right payment structure depends on your project’s risk profile, timeline, and financial realities. Consider factors like:

GCPay is a cloud-based platform built specifically for construction payment management. It automates pay applications between general contractors and subcontractors, helping teams create, review, and approve applications faster.

The platform also streamlines lien waiver exchange, compliance document collection, and retainage tracking. With ERP and accounting integrations, GCPay reduces manual data entry and improves accuracy. Teams gain visibility through dashboards and reporting, while electronic payment tools help get subcontractors paid faster and with fewer administrative bottlenecks.

Autodesk Construction Cloud (ACC) connects financial management, project workflows, and documentation in one centralized platform. Teams can manage budgets, track costs, oversee change orders, and monitor payment applications alongside daily project activity.

Because financial data links directly to field progress and documentation, everyone works from the same source of truth. This reduces silos between accounting and operations, improves forecasting accuracy, and keeps payment schedules aligned with real-time project performance. By centralizing contracts, compliance documents, and approvals, ACC helps contractors stay organized and financially in control.

The right tool should simplify payments, not create more work for your team.

Make sure the software connects directly to your existing ERP or accounting platform. Seamless integration reduces duplicate data entry and minimizes errors. When financial data flows automatically between systems, your team saves time and maintains accurate records.

Payment tools should be easy to use for everyone, from project managers in the field to accountants in the office. Look for intuitive dashboards, clear navigation, and mobile accessibility. If the system feels complicated, adoption will suffer.

Strong onboarding makes a big difference. Ask about implementation timelines, live training sessions, and ongoing support resources. A vendor that invests in customer education helps your team get value from the software faster.

Do not rely on marketing alone. Request a live demo or trial access so your team can see how the platform handles real workflows. Testing the system helps you evaluate usability, reporting, and approval processes before committing.

Construction billing is complex. Confirm the platform can manage retainage calculations, progress billing, lien waivers, and compliance documentation. The more industry-specific functionality it offers, the fewer manual workarounds you will need.

Choose software that can grow with your business. Whether you take on larger projects, expand into new markets, or add more subcontractors, your system should handle increased volume without requiring a full replacement later.

A solid contractor payment schedule is essential for keeping your project financially healthy and on track. With the right structure, documentation habits, and software support, you can reduce disputes, maintain steady cash flow, and foster stronger client relationships.

Switching construction management platforms isn’t something that teams can do on a whim. You’re not just buying new software (which can be a massive financial investment), but you're also budgeting for migration costs, carving out time for training, and figuring out how to keep live projects moving throughout the process.

If not done right, switching platforms can be challenging. But if you have the right platform and migration plan, the effort and investment will pay off.

Case in point: Cleveland Construction, a national general contractor serving markets like K-12, multifamily, hospitality, and historic adaptive reuse.

Cleveland Construction started looking at Autodesk Construction Cloud (ACC) after evaluating the costs of Procore, their software at the time. The firm ultimately made the switch not only because the cost model no longer made sense, but because they saw an opportunity to modernize how their teams worked.

In our recent webinar, From Procore to ACC: Cleveland Construction’s Blueprint for a Seamless Transition, leaders from Cleveland Construction and its implementation partner, IMAGINiT, shared their step‑by‑step migration process, the business drivers behind the change, and the unexpected wins they achieved with ACC.

Clear communication and transparency are some of the key pillars of successful change management. This is particularly important if you’re swapping a major part of your tech stack, like your construction management platform.

Since multiple teams are impacted by the platform change, you need to set the context and build buy-in early.

This is exactly what Cleveland Construction did.

“The biggest thing we did right out of the gate was explaining to everybody why we were looking at ACC and why it made sense from a financial standpoint,” said Elliot Christiansen, Sr. Vice President of Operations at Cleveland Construction.

In addition to explaining the “why” behind the switch, Elliot also involved users and stakeholders in a number of software demonstrations and got their input.

Teams were brought in after the selection process to use ACC in a hands-on, practical way.

“We got them involved in creating forms and making sure that the daily job report was the way the superintendents wanted it. We also made sure that the approval workflows were a way that would work for our project management staff,” recalled Elliot.

All of that was easy to do with ACC thanks to the platform’s modular structure that enabled teams to align new workflows with the company’s existing operational needs.

All in all, Elliot says that involving teams beyond the executive level helped make the transition smoother.

Don’t just treat the migration process as the means to swap your software; rather, view it as an opportunity to level up your processes.

Many teams migrate by trying to recreate their old system inside a new one. Cleveland Construction used this transition as a strategic opportunity to modernize workflows, eliminate legacy friction, and standardize processes company‑wide.

Elliot and the team didn’t approach migration as a one-to-one rebuild. They treated it as a chance to step back and ask harder questions about how work actually gets done.

According to Elliot, this is an approach that he would’ve doubled down on, knowing now how beneficial it was to implement those changes as the firm migrated to ACC.

“I would have spent more time thinking about what in the company I would change, when it came to how we do things,” he explained. “Do we need to change some of our workflows? Do we need to change some of our sign-off thresholds? This is a great opportunity to do those types of things.”

One excellent example of this mindset in practice is how Cleveland reworked its approval workflows. Instead of routing internal approvals through DocuSign, Cleveland now handles those workflows directly in ACC.

“Even internal approvals were done in a DocuSign envelope,” Elliot said. “So we were paying for it every time, even if it got rejected.”

With ACC, internal approvals happen in-platform, and only finalized items move to DocuSign for external signatures. The same thinking applied to subcontract generation. Templates now auto-generate from the cost tool, route for signature, and save back automatically. “It probably reduced our contract admins’ workload by 75%,” Elliot noted.

Switching platforms can be daunting. The good news is that you don’t have to do it on your own. Find a partner that can support with transitioning your workflows, leveling up your processes, and keeping the rollout on track.

For Cleveland Construction, that provider was IMAGINiT Technologies, an Autodesk Platinum Partner that helps firms implement technology solutions and maximize their ROI.

Vince Daniele, IMAGINiT's Construction Solutions Team Manager, says the key is to treat implementation as a structured, phased process that starts with deep discovery. “We meet with different teams and really understand how they’re using their current platform,” Vince explained. From there, IMAGINiT typically configures a foundational ACC project template and train a core group of admins using real workflows.

What made Cleveland’s rollout faster was using live data. IMAGINiT migrated an active Procore project into ACC so teams could train in an environment that already felt familiar. “They weren’t just seeing a new tool,” Vince said. “They were seeing their own RFIs, sheets, and logs.”

After go-live, IMAGINiT stayed involved with mentoring and fine-tuning. The result was a smooth transition completed in just three to six months.

If your construction management platform doesn’t work for the field, it won’t get used consistently, no matter how powerful it is.

Cleveland kept field teams in mind throughout the entire process. In addition to having superintendents in the loop from the get-go, they built mobile‑first experiences with easy forms, fewer clicks, and in‑context automation.

All that effort paid off, with ACC being quickly adopted in the field.

ACC was well received by Cleveland Construction’s field teams, which was one of the biggest surprises of the rollout. “That’s actually where I thought I’d get the most pushback,” Elliot said.

Daily reporting was a major concern early on. “Procore has a very good daily log tool,” Elliot said. “But by spending time with Vince and his team to really get this right in the forms tool, I think we actually have a better setup in Autodesk than we had before.” Cleveland rebuilt daily reports using ACC Forms and Issues, turning them into structured, field-friendly workflows instead of free-text logs.

Superintendents now answer simple yes-or-no questions, like whether a job was delayed by weather. If the answer is no, they move on. If it’s yes, ACC requires them to create an Issue before they can close the report. That Issue pulls from a predefined template, with dropdowns instead of typing, and automatically notifies the right people. The same logic applies to deliveries, inspections, and other delays.

“We combined multiple forms our teams used to fill out into one,” Elliot explained. “It made it easier for everyone.”

Field teams also responded well to ACC’s mobile experience. The system tags photos, captures GPS location, and behaves much the same way teams were used to. Sheets and markups worked as expected, and the mobile app let teams choose which projects to sync so devices didn’t get overloaded. “If you’re working on multiple projects, you’re not eating up all the memory on your device,” Elliot added.

Even scheduling landed well. “The schedule tool has been very well received,” he noted, especially since updates can now happen directly from the field.

Upgrading your construction management platform doesn’t just benefit your internal teams; it can also remove friction from how you work with external partners.

In the case of Cleveland Construction, ACC helped enhance collaboration between the firm’s teams and the external architects they worked with.

"It wasn't necessarily something that I thought about when we were evaluating it originally, but as a byproduct of switching, we do have a much easier time coordinating RFIs and submittals with our architecture partners. We always used to get a lot of pushback forcing Procore on them,” remarked Elliot.

With ACC, Cleveland was able to meet its partners where they already work. “Now we’re giving them access to ACC,” Elliot explained. “Most of them already have an account, so we can bridge folders together.”

That flexibility opened the door to deeper integration. Using IMAGINiT’s Pulse integration platform, Cleveland now syncs submittals between its ACC environment and an owner’s ACC system. Submittals move automatically into the owner’s workflow, route through architect review, and return with statuses like approved, approved as noted, or revise and resubmit. “That was never something we could have accomplished in Procore,” Elliot said. “They never worked together that well.”

Trade partners benefited too. According to Elliot:

“We're starting to notice that a lot of the subcontractor trades have used ACC quite a bit and are pretty familiar with it. Some even have their own accounts, and it's easy to share files back and forth.”

Asking people to adopt a new platform is a big ask, so identifying, communicating, and celebrating wins—big and small—can build momentum.

Early proof that the switch is working gives teams more confidence, especially when those wins show up in their day-to-day work.

Some of the biggest wins that ACC helped Cleveland Construction achieve include:

Beyond that, Elliot also called out incremental wins, like saving 30 seconds at a time throughout the day.

Projects now start with hundreds of files already loaded instead of being manually uploaded. And because ACC uses flyout windows rather than full-page reloads, teams stay in their flow. “It sounds like a small detail,” Elliot said, “but if you’re saving 30 seconds a hundred times a day, it adds up. It’s a little thing, but it goes a long way for a project team.”

Switching platforms doesn’t have to mean disruption. Cleveland Construction’s experience shows us that when you involve stakeholders early and engage the right implementation partner, migration can become a catalyst for better workflows and stronger collaboration.

Watch the on-demand webinar to see how Cleveland Construction planned, executed, and scaled their move to Autodesk Construction Cloud.

In this episode of Digital Builder, host Eric Thomas sits down with Michael Baim, Vice President of Venue Infrastructure at the LA28 Olympic and Paralympic Games, and Allison Scott, Director of Sustainability Growth and Engagement at Autodesk, to explore what it takes to deliver the LA28 Games with fewer than 1,000 days to go. As Los Angeles prepares to host the Olympic Games for a third time, and one of the most ambitious Olympic and Paralympic Games in modern history, Michael and Alli’s conversation highlights the scale, complexity, and collaboration behind LA28’s no-new-permanent venues plan, their ambitious commitment to build LA28’s footprint by adapting existing or building temporary infrastructure.

Michael and Allison discuss how Autodesk’s Design and Make platform, including Autodesk Construction Cloud, will help teams coordinate logistics, data, and planning across an unprecedented program. They also touch on balancing historic venue preservation with modern upgrades, the long-term community legacy LA28 aims to create, and opportunities for contractors, designers, and builders to get involved in bringing the Olympic and Paralympic Games to life.

We discuss:

Digital Builder is hosted by me, Eric Thomas. Remember, new episodes of Digital Builder go live every week. Listen to the Digital Builder Podcast on:

or wherever you listen to podcasts.

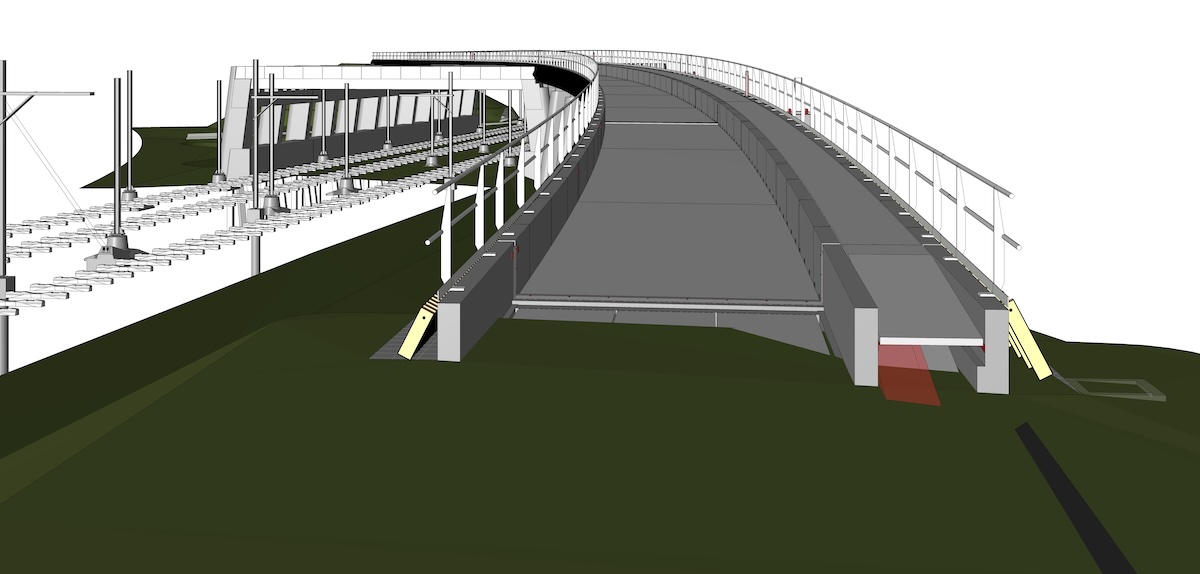

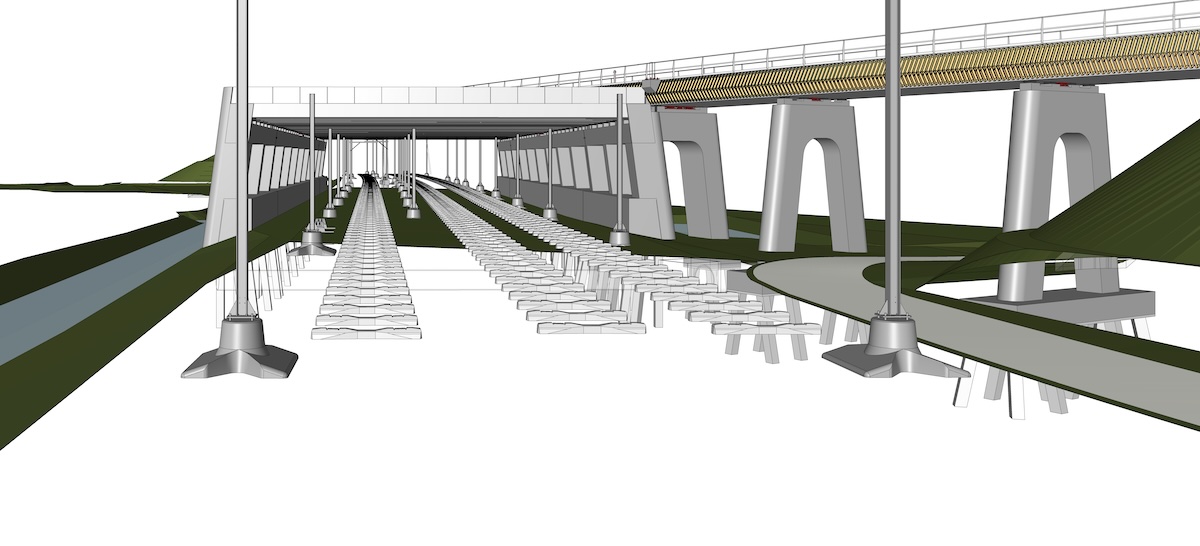

At the heart of the Netherlands’ railway network, a critical junction in Zuidwestboog Meteren is undergoing a massive transformation. The project – part of a broader programme to enable high-frequency rail traffic – focuses on a complex intersection where the Betuweroute, a dedicated freight line from Rotterdam Harbour to the German border, meets the passenger lines connecting Utrecht and Den Bosch.

For Van Hattum en Blankevoort, the concrete contractor division of VolkerWessels, the task is as high-stakes as it is technically demanding. “We’re responsible for construction works underneath the rail line itself,” explains Pieter Prins, BIM Manager at Van Hattum en Blankevoort. “That includes soil work, concrete foundations, and bridges – all covering nearly 3km of track.”

Along that line is the impressive Pergola construction, a bridge extending almost 200 metres designed to let freight and passenger trains cross paths safely. “The Dutch infrastructure market has a separate challenge,” explains Pieter. “We’ve got a massive volume of work and significant grey-out – a lot of knowledge held by experienced people is expected to be lost on short notice. That’s why it’s essential to collect information centrally, contribute widely, and recruit where we can.”

“Autodesk Construction Cloud is already central to our work. It represents a major step forward.” - Pieter Prins BIM Manager, Van Hattum en Blankevoort

The ProRail programme in Zuidwestboog Meteren focuses on improving capacity at a key crossing, with nearly three kilometres of work in a tight area where phasing and live infrastructure shape the plan. Van Hattum en Blankevoort’s scope sits beneath the track, which makes coordination especially unforgiving: small mismatches between disciplines can become large fixes once construction sequencing is underway.

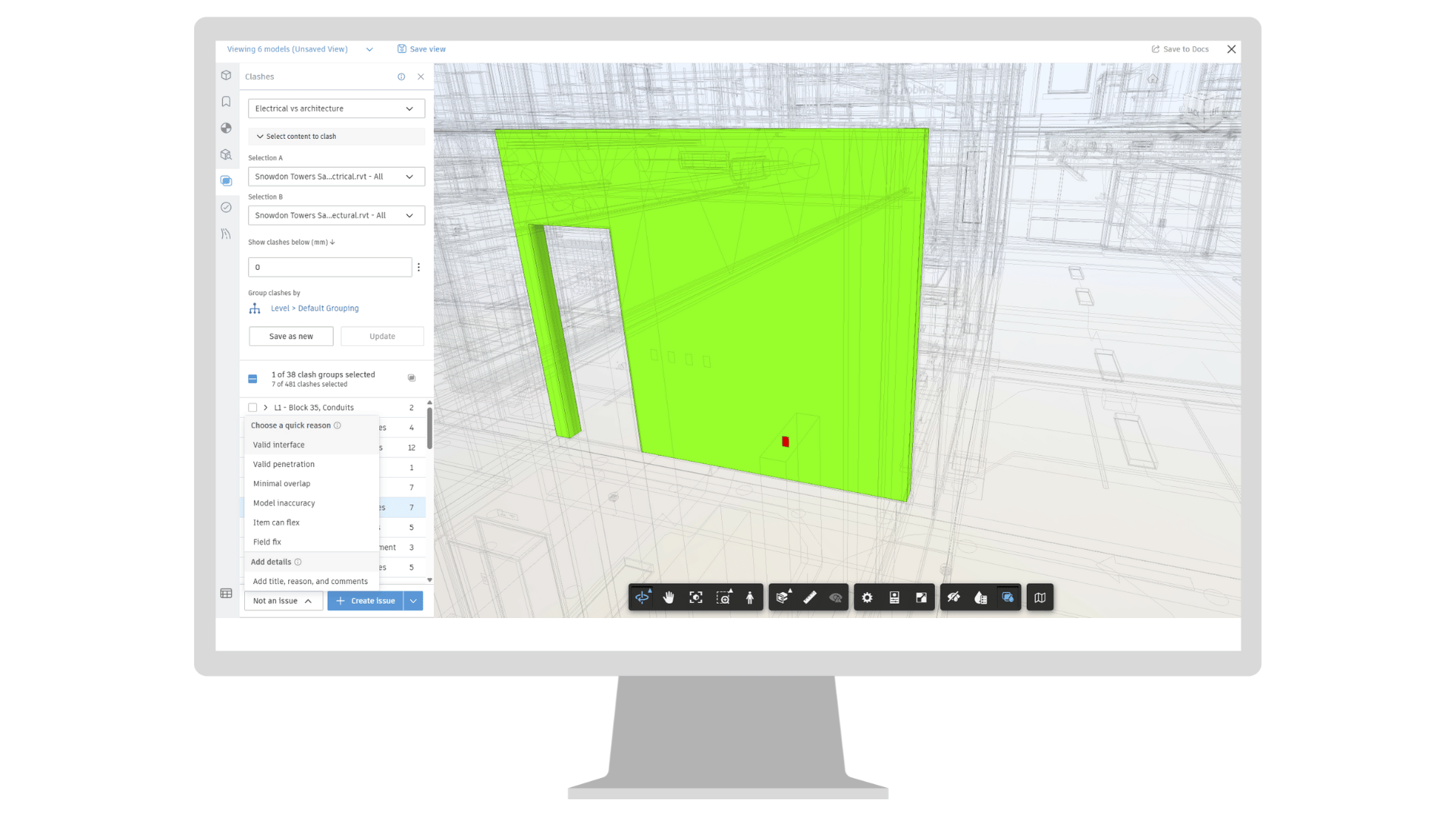

To manage the immense data and collaboration requirements of the Meteren project, VolkerWessels transitioned to Autodesk Construction Cloud (ACC). Since they had previously used BIM 360, the move to ACC was a natural evolution that let the team centralise every facet of the design and construction process. By using a suite of integrated tools – including Revit, Civil 3D, and Navisworks – all funnelling into ACC, VolkerWessels created a unified common data environment for the project.

“In the past, remarks would get lost in email,” says Pieter. “With ACC, none of the comments are lost during the review processes. It connects everything together.” This transparency is crucial not only to ensure accurate feedback on the Meteren project, but also to archive and collate mission-critical knowledge for use in the future.

One of the project’s most innovative aspects is its integration of Autodesk Workshop XR. Using Meta Quest 3 VR glasses, the project teams conduct virtual safety walks of the construction site before a single cubic metre of concrete is poured. By pulling coordination models into a virtual environment, engineers and site managers can walk through the proposed phasing of the project, allowing them to interact with the design and identify potential gaps or safety hazards at an early stage, even before physical implementation.

“It’s a good way of working and a low-barrier way of exploring Workshop XR,” notes Pieter. “Setting up VR experiences like this really helps us a lot. We address issues through the issue module, which interacts directly with ACC for tracking and registration – so everything is completely integrated.”

The shift to a centralised, cloud–based workflow has yielded measurable improvements in both communication and speed. According to Pieter Prins and Peter Kanninga (Director Integral Projects), ACC has been vital in achieving Van Hattum en Blankevoort’s goals.

“We’re always looking for innovative solutions that boost collaboration, cut failure costs, and increase productivity,” says Pieter. “Digital workflows have already halved our physical review rounds, taking the average down from four to just two. Real-time access through the Autodesk Desktop Connector and Revit Cloud Worksharing has also slashed wait times for retrieving and syncing models by 30-40%. Most importantly, by integrating Model Coordination and clash detection in ACC, we’ve resolved 75% of clashes before physical construction even starts”.

Beyond these high-level wins, VolkerWessels uses standardised templates and instructions, letting them onboard new team members and external contributors in just 30 minutes. Design leaders also use model coordination to search for clashes themselves, solving interfaces at their desks before they enter the final design phase. The team uses the “Bridge” module in ACC to exchange models and data with third party providers, such as those designing the overhead power cables.

The project’s set for a phased implementation through 2027-2028, involving redirecting highways and the Betuweroute freight line. Meteren’s ongoing success is supported by a strong partnership between VolkerWessels and Autodesk, using a specialised coaching programme to master new developments like Dynamo for Revit and Civil 3D. By replacing fixed assumptions with a data–driven simulation of the site, VolkerWessels is ensuring a smoother rollout and a more resilient rail network for the Netherlands.

“Autodesk Construction Cloud is already central to our work,” says Pieter. “It’s being deployed on all scales of project – it represents a major step forward.”

By transitioning to a unified common data environment, VolkerWessels is able to bridge the gap between complex engineering disciplines and real-world implementation. The integration of Autodesk Construction Cloud allows the team to resolve 75% of clashes before construction begins, halving physical review rounds and ensuring that critical institutional knowledge is preserved for the future of Dutch infrastructure.

As the world moves toward more complex challenges, human-centered design becomes more important than ever. Whether we’re rebuilding after natural disasters or designing healthcare facilities, the built environment plays a critical role in how people heal, connect, and move forward.

But what exactly is human-centered design, and what does it look like in practice?

We answered this question and a whole lot more during this special episode of the Digital Builder podcast filmed live at the Autodesk Technology Center in Boston. This conversation is part of the launch of our new Make It Heal film series starring New England Patriots quarterback Joshua Dobbs. The event also kicked off the 2026 Design & Make It Real program, an initiative that empowers students to develop digital skills, explore careers in architecture, engineering, construction, and operations, and design solutions that help communities recover and thrive.

In this episode of Digital Builder, I’m joined by New England Patriots quarterback and aerospace engineer, Joshua Dobbs, and Gerard Georges, Director of Architecture at Build Health International.

We dig into the concept of human-centered design and explore everything from designing with empathy and purpose to the role that technology plays in improving collaboration.

We discuss:

As the term clearly illustrates, human-centered design starts with people. It goes beyond plans or blueprints, and instead puts the humans (i.e., the people designing buildings and those using them) at the heart of the build.

“Human-centered design is really around making an environment, a culture, a community that inspires and supports the basic human person. We all want to engage with each other. So, we need to think about spaces that support that engagement,” remarks Gerard.

He highlights the importance of designing environments that encourage connection and healing. That could be through biophilic design, access to natural light and views, or creating buildings that can withstand changing climate conditions.

In addition, Gerard stresses that it’s crucial to think beyond the immediate end user; builders should also consider how spaces will serve future generations.

Josh weighs in with his observations on the design side. For him, human-centered design shows up in how diverse perspectives and problem-solving approaches come together to improve outcomes.

“I also think about the designers. I think it's cool just seeing the different backgrounds of the designers and their thought process, their problem-solving skills, their creativity—and seeing how it comes to life.”

He continues, “That's what's been so unique about learning about the Autodesk software, and how it’s able to make things come to life quickly. You're able to see multiple iterations of the solution to a problem. You're able to see how it fits in different places and different environments. And I think being able to have multiple choices and then being able to go through the data and decipher what the best solution for the problem is really cool.”

Human-centered design really comes to life when a project serves the community in a meaningful way.

Gerard explains that such projects stem from teams having a shared commitment and collaborative approach.

“We really strive ourselves on the idea of collaboration, communication, and shared outcomes. So, as long as we all come to the table with that mindset, we really have a great roadmap to move forward with our projects.”

“So how do we do that? We have user or stakeholder engagement sessions where we really try to understand priorities, needs, and goals. And then we think about how we influence the notions of sustainability and resiliency in each project that we work on.”

Josh agrees and notes that one way people can build that shared understanding is by seeing the work take shape before it hits the job site.

“I think just people coming together is extremely important. One thing that stood out was the VR session, where you're able to walk through the process of what it looks like to build something. It's very similar to what we do on the field, where we go through various walkthroughs before the games. When you're in that moment, you're able to see things come to life the right way.”

Lessons around teamwork are most visible in sports because success depends on people with very different backgrounds working toward a single outcome.

With that in mind, Josh points out that the same dynamic shows up on construction and design teams. Everyone brings their own experiences to the table, and that diversity is what makes teams stronger.

“I think the biggest thing is that everyone has their own unique background that got them to wherever they are,” Josh says. “In our complex in Foxborough, everyone comes from different places. I come from Atlanta, Drake [Maye] comes from North Carolina, Stefon Diggs comes from Maryland, and so on. But it’s all the work we’ve put in, and all the past experiences we’ve gone through that allow us to come together, apply what we know, and ultimately win on Sunday.”

Another lesson that’s highly visible in sports? The ability to perform in high-pressure situations.

Here, Josh says that teams can turn that pressure into excitement by being well-prepared for anything.

“It comes down to your preparation. For us, the season starts in April, when we go through our off-season activities and go through fundamentals, while getting the flow of the plays. Then you go through the beginning of the season where you're put in different situations, and you have a chance to go out and perform.”

He continues, “I think in every single industry it is the same. It's the habits that you've created studying; it's the habits you've created working with other people. It's those reps that you build up over time.”

“And so, at the end of the day, because of that preparation, if you do it the right way, you don't really feel the pressure. You're just excited to perform and achieve your goal at the end.”

For Gerard, staying composed comes down to trusting the process and staying flexible when conditions change.

“We have to be flexible, malleable enough to say, ‘Okay, can we get to this goal? But maybe we're taking a different path, maybe we're introducing a different system or a different partner to end up getting to this process.’”

“So, dealing with stress is really thinking about the risks you might face. Then determining how to address those risks and determine the strengths of your team to be able meet your goals. So, there's always this inner chaos that happens, but having a measured approach is always beneficial for me personally as well as for the team.”

Great teams, whether on the football field, office, or job site, become even better when there’s strong leadership behind them. And to be a strong leader, you need to show up for the people around you.

As Josh puts it, “You have to be a great teammate first, and how you learn and get to know the people around you. And then, after that, it's about making sure you're doing the work first. I think a lot of leaders like to lead from the front and drag people behind, or they like to tell people what to do instead of leading by example and doing the work, putting in the time and effort that their other coworkers or teammates are doing.”

He continues, “And so it's all about being consistent and being a great teammate. And I think if you do that, then when you're in your leadership role, you're able to pour into your teammates and collectively accomplish a goal.

As for Gerard, he sees empathy as the foundation of effective leadership.

“Empathy is really the word that comes to mind as a leader. A good leader leads by example, I believe. The way to do that is to understand the needs of your teammates, your community, as well as the stakeholders that you're working for.”

“Once you understand what their goals and their needs are, you make space for them to contribute. And I think that makes them feel like they have power. It gives them agency. So by leading by example and then leading with an empathetic thought, you're allowing others to flourish, and they support you.”

Digital Builder is hosted by me, Eric Thomas. Remember, new episodes of Digital Builder go live every week. Listen to the Digital Builder Podcast on:

or wherever you listen to podcasts.

Construction estimating requires precision, consistency, and collaboration across your entire team. One of the most powerful features in Autodesk Estimate is the centralized cost library, a tool designed to transform how your organization manages pricing data and creates estimates.

The centralized cost library is a customizable, account-level repository that consolidates all of your pricing information in one accessible location. This shared resource ensures that everyone on your team works from the same accurate data, eliminating discrepancies and reducing errors in your estimates.

The cost library allows you to organize and maintain all essential pricing components:

By housing all this information in a single location, you eliminate the confusion that comes from scattered spreadsheets, outdated price lists, and inconsistent data sources.

Beyond individual cost items, the centralized library enables you to build custom crews by combining labor and equipment resources. This feature is particularly valuable for standardizing how your team approaches common cost groupings.

When you create crews, you can:

The centralized cost library delivers three critical benefits that directly impact your bottom line.

The centralized cost library represents more than just a database. It's a strategic asset that standardizes your estimating process and creates a foundation for continuous improvement. As your team uses the library across multiple projects, you build institutional knowledge and refine your pricing based on real-world results.

For construction companies looking to scale their operations while maintaining quality and accuracy, the centralized cost library in Autodesk Estimate provides the infrastructure needed to support growth without sacrificing precision.

Want to dive deeper? Check out our on-demand webinar, Cloud-Based Estimating Starts Here: Meet Autodesk Estimate.

Any construction pro would agree that preconstruction is an important phase in the project lifecycle. After all, this is when teams make key decisions around things like budgets, schedules, and labor.

But as construction becomes increasingly complex (think: larger projects, labor shortages, and sustainability commitments), there’s a strong case to be made that preconstruction is more than a “step” or “phase” of the project.

Beyond being just a procedural step, we believe that precon is also a strategic advantage.

And the teams that recognize this are the ones that consistently win more work and protect profit.

In construction, last-minute planning and decision-making aren’t just inefficient; they’re also risky and expensive.

Construction projects become more complex as they progress, which means fewer options and greater consequences. When decisions are made late in the game, they can trigger rework, change orders, or delays that ripple across the entire project.

The old mindset of fixing issues once construction is underway no longer holds up. There’s simply less room for error.

To stay competitive and protect margins, owners and builders need a predictable, data-informed foundation that reduces uncertainty and supports better decision-making. The only way to achieve that is to start early and address risk and alignment before the project kicks off on the jobsite.

Planning ahead and making critical decisions early in the project leads to clearer expectations, fewer downstream surprises, and a smoother project overall. All of these things make life easier for owners, GCs, and subcontractors

Owners who prioritize early planning gain better cost certainty and reduce unexpected expenses and delays that kill their bottom line. Meanwhile, GCs that actively collaborate with design partners early on can reduce conflict, accelerate buyout, and avoid change orders.

The right practices also benefit subcontractors. When preconstruction is coordinated and scopes are clear, they get more accurate scopes and fewer rebids, so they don’t have to waste time pricing with incomplete data or shifting information

To effectively plan ahead, you need the right tools. Equip your team with a platform that can facilitate your preconstruction processes, from takeoff and estimating to document management, bid coordination, and scope development.

For best results, choose a platform that centralizes workflows and connects to downstream project phases, so decisions made in preconstruction don’t get lost or recreated later.

Specifically, you want to have workflows that are:

All of the above are critical because preconstruction sets the tone for the entire project lifecycle. It doesn’t matter how well-intentioned or detailed your plans are; if your tools, teams, and processes are fragmented, you will still encounter inefficiencies, misalignment, and errors.

When teams get preconstruction right, they work more efficiently and reduce avoidable risk.

Here are a few examples of how strong preconstruction practices pay off:

So far, we’ve discussed why and how preconstruction can give you a competitive advantage. With that, here are the steps you can take to turn preconstruction into a core strength, not just a phase of work.

Map current workflows to spot duplicate work and risky handoffs. Look for areas where people need to re-enter data or where details aren’t documented. These gaps often signal where delays, errors, and rework originate later in the project.

Consolidate tools into a connected platform to unify estimating, takeoff, bid management, and documents. This is a tall order, as most teams rely on a patchwork of disconnected tools built up over time. Fortunately, Autodesk Construction Cloud (ACC) brings those workflows together in one connected environment.

Standardize templates, forms, meetings, and assumptions so teams aren’t reinventing the wheel on every project. Consistency creates clarity and makes it easier to compare performance across projects, so can you gather and implement learnings.

Set up frameworks for how data is created, updated, and shared, along with naming and version conventions that everyone follows. That way, teams always know which information to trust and where to find it.

You need your team’s input when designing workflows and setting expectations. That’s why it’s important to build cross-functional collaboration into preconstruction routines. One example is to have weekly design-precon syncs to surface risks early and align decisions.

Define a short list of KPIs that reflect preconstruction performance, not just outcomes. Track estimate cycle time, win rate, variance to baseline, and change-order volume to help teams measure progress, identify gaps, and improve consistently.

Train teams using clear, consistent communication standards so everyone understands expectations, tools, and workflows. Good training reduces friction, increases adoption, and helps teams work confidently without relying on tribal knowledge.

Transforming your preconstruction practices doesn’t happen overnight, but that doesn’t mean you and your teams won’t experience wins right away. If you’re looking for momentum, here are some things you can quickly implement:

The construction landscape is rapidly changing, and projects are more complex than before. Companies that want to thrive in today’s environment must change how they view preconstruction.

It’s no longer just a step or box to check. When done right, preconstruction can pave the way for better collaboration, lower project risk, and a healthier bottom line.

Want to centralize, streamline, and de-risk preconstruction? Explore the Autodesk Preconstruction Bundle—your connected solution for estimating, takeoff, bid management, qualification, and documentation.

As a construction owner, your everyday list of to-do's boils down to two things: increase profit and reduce risk. This is why it pays to improve visibility and collaboration with construction teams through technology. You get to be more hands-on with progress transparency while empowering project teams to work smarter.

In engineering and construction, around 95% of all data goes unused, which often creates disconnects. By integrating this otherwise “lost” data into multi-team workflows (if not your own), you can finish projects on schedule, under budget, with higher quality, and have peace of mind that that progress is auditable across the entire project lifecycle.