PREMIUM MOUNTING TECHNOLOGIES GMBH & CO. KG

Digital transformation for a place under the sun

DIGITAL DEVELOPMENT AND INNOVATION

Share this story

PMT drives the energy transition

Rapid growth and excellent prospects for the future: Premium Mounting Technologies GmbH & Co. KG, or "PMT" for short, builds aerodynamic photovoltaic substructures and industrial carport systems for customers throughout Europe – and does so in a particularly safe, practical and quick-to-assemble manner. Digital, collaborative and sustainable processes have helped PMT develop and test new products since the company was founded in 2012, making business growth possible despite major challenges.

More energy for innovation

Innovations are hard work. PMT, a manufacturer of photovoltaic substructures from Bavaria, shows how they can be made easier using digital methods.

Modern PV systems are highly efficient at converting sunlight into electricity.

Green energy needs support

PMT came along at the right time: The demand for true sustainability is greater today than it has ever been. And at the latest with the Green Deal and the EU taxonomy, political rethinking is also taking place on a grand scale. One component of the green energy mix in this country is the generation of solar energy. More precisely: through photovoltaic systems, mostly space-efficiently mounted on roofs and carports. Commercial buildings with many square metres of space are especially upgrading their roofs. To get an idea of the scale of PMT's work, CEO Jörg Weber draws an impressive comparison: "In some cases, we equip roofs with PV systems that are ten times the size of the Allianz Arena in Munich."

Jörg Weber, COO Premium Mounting Technologies

Certified innovation

A challenge in the process: Roofs are complex building components, and there are virtually no standard solutions. In addition, solar module sizes are constantly changing, which leads to ongoing product adjustments and developments. Developments are tested and optimised through wind tunnel testing, component trials and theoretical calculations to ensure that the substructures meet the highest safety requirements and defy overall statics, wind and snow. PMT offers substructures for photovoltaic systems, which, depending on the model, can be installed quickly with a specially developed click system, while providing maximally long material efficiency and also extremely high stability. The Upper Franconians have had this expertise certified for their aerodynamic flat roof system "PMT EVO 2.0": The systems have received general building authority approval (abZ) from the German Institute for Building Technology (DIBt) – one of the first companies in the industry ever to do so for such a substructure. Weber emphasises, "It is not easy to obtain approval. So, it is definitely an achievement and we are very proud of it."

"As a businessman, I would say: The software is paying for itself sooner than expected."

— Jörg Weber, COO Premium Mounting Technologies

Mounting systems must be quick and safe to install.

Realising ideas faster

When the Premium Mounting Technologies brand took the stage in the sustainable energy industry in 2012, it created trade show experiences that made an impression: Interested visitors could not only view the substructures, but also try them out, click on them – and then also take them home as a digitalised animation directly on their smartphone or tablet. From the very beginning, PMT has combined high innovation with ensuring the highest safety standards. Jörg Weber attributes this to PMT's digital way of working. Early on, the company digitised many business processes, used collaborative software tools and also mapped the ERP (Enterprise Resource Planning) system completely digitally. Yet PMT's digital transformation is still in full swing. "Last year alone, we spent a six-figure amount on new software solutions." He and his colleagues feel the positive results every day, and innovations are now much cheaper and more quickly ready for the market. "The digital processes save us valuable time. As soon as we have launched a new product on the market, we use the time gained to further develop existing products such as EVO 2.0 and accessories. That's how we always stay innovative."

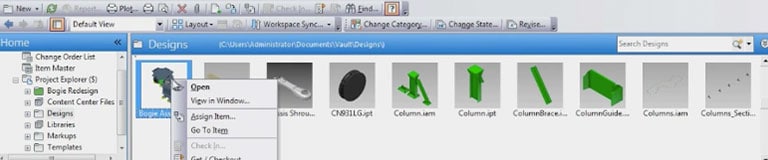

From idea sketch to finished 3D model, PMT works with the PDM Collection.

More time, security and efficiency

Marlon Wagner, Head of Engineering at the University of Vienna, describes how digital work works in everyday life PMT. His teams work with Autodesk's PDM Collection and used Inventor and AutoCAD from the first draft idea. "The digital workflow is completely synchronised for us. It starts with the development, goes to production with our suppliers and in parallel we already create the assembly instructions as well as packaging instructions. The common 3D model is the focus all the time."

By using Inventor Nastran (US site), structural engineers can quickly find potentially damaging stress points in the components, which increases stability enormously. The models are stored in the product database Vault right from the start, so all project participants, from development to purchasing, marketing and sales, can always work with the same up-to-date 3D model. This prevents errors due to old data, avoids misunderstandings in communication and also allows teams at several locations throughout Germany to work together easily. And by the way, Premium Mounting Technologies saves costs and CO2 through fewer staff trips. In the future, the company will link the PLM system with its own enterprise resource planning system. This will allow it to optimise the process flows even further.

"Thanks to the digital way of working, the exchange with development and suppliers is much faster and more flexible. We get to the finished product very quickly."

– Marlon Wagner,Head of Engineering, Premium Mounting Technologies

The 3D model makes the finished construction tangible right from the start.

Challenge as part of the DNA

In addition to the shortage of raw materials and delivery bottlenecks due to a lack of trucks, COO Jörg Weber describes the shortage of skilled workers as a pressing problem. That is why he makes a point of ensuring that every workplace is equipped with the latest hardware and software – because free coffee and filtered water are no longer enough to make a company an attractive employer. His employees already benefited from digital logistics at the beginning of the pandemic. The completely cloud-based infrastructure made it possible to react PMT quickly and let a large part of the staff work from home from one day to the next. And when major trade fairs were cancelled across Europe, Weber and his colleagues used the digital marketing channels they had already established to get in touch with potential international customers as well. "Digitalisation has helped us a lot in the past and we also see great opportunities for the future, for example in the distribution of our products." Today, customers have the opportunity to see products virtually in advance. This advantage is especially appreciated by the sales department for customer acquisition.

Partnership with Autodesk

Since day one, PMT the company has relied on its partnership with Autodesk and permanently integrates new software into the existing infrastructure. Another facilitating factor is that both established and new employees are already accustomed to working with Autodesk software through their training, which makes it easy to adapt processes, as the solutions are already established on the market. Wagner adds, "I just really enjoy working in this development environment."

"We get excellent service with fast response times."

– Jörg Weber COO, Premium Mounting Technologies

New PMT developments are built and tested in-house.

The company

Premium Mounting Technologies GmbH & Co. KG develops and produces aerodynamic photovoltaic substructures for all types of roofs on commercial buildings and builds industrial carport systems. PMT has its headquarters in Stadtsteinach in Upper Franconia, was founded in 2012 and was initially a supplier of flat roof constructions for common solar systems. Today, with almost 70 employees, the company develops individual and customised solutions for flat and pitched roofs according to the highest safety and quality requirements for the global market.

More about the products

-

Professional-grade product design and engineering tools for 3D mechanical design, simulation, visualisation and documentation.

-

Product data management software — available as Vault Basic, Vault Professional, Vault Office

-

Get Inventor + AutoCAD + Autodesk Fusion + more – Professional-grade tools for product development and manufacturing planning.

Learn more