Streamwood high school

Making students job-ready is a matter of precision

Education

Share this story

Professional prep for an industry career

Streamwood High School’s precision manufacturing lab prepares students for the world of work with the help of Fusion 360 CAD/CAM software.

Instructor Matt Erbach (left) with student Nathan Padgett.

A tradition of manufacturing education

As a prize-winning instructor of precision manufacturing, Matt Erbach knows a thing or two about what it takes to train the next generation of skilled professionals in this rapidly evolving and technical industry. He also knows that there’s more to precision than just the process of machining parts; it also takes communication and teamwork. A National Institute for Metalworking Skills (NIMS) and Project Lead the Way (PLTW) certified instructor, Erbach teaches at Streamwood High School in Illinois, which boasts one of the largest precision manufacturing labs in Illinois, and has taught manufacturing there since its founding in 1978.

VIDEO: Watch as Instructor Matt Erbach highlights how Fusion 360 has exposed these teenagers to computer numeric programming, milling, lathe operations, and quality control.

Modern results

“I had no exposure to manufacturing until I hit college; I didn't know that manufacturing was a thing within high schools,” says Erbach, who has a master’s degree in workforce development and worked in the trade industries for years before transitioning to teaching.

His expertise and passion for excellence have propelled him to the forefront of education, where he tirelessly imparts not only technical knowledge but also invaluable real-world insights to aspiring engineers and machinists, “Now I get students up to a very high level of skill and make them job-ready and university-ready,” he says. “I have students working on a level that I never thought was possible up until a couple of years ago.”

CAD and CAM on a single platform

Part of what’s changed in those last years includes the launch of Autodesk Fusion 360 online. In addition to running Fusion on Macs and PCs, students can now access Fusion 360’s full functionality of integrated CAD and CAM programming within a web browser, using the Chromebooks they have access to. “At the height of COVID, it saved my instructional year,” Erbach says. Now that COVID lockdowns are over, students still benefit from collaborating with each other using Fusion 360 online at home and can pick up right where they left off when back in class.

Also, because Fusion 360 is a cloud-based platform built for collaboration, it has unlocked new ways for Erbach to work with his students. “Fusion 360 has changed the way I interact with students and provide feedback simply because I can access the same files they can at the same time,” he says. “And it allows students to design and manufacture within the same platform. We get them in the comfort zone with the design side and then there's almost no change for them to start manufacturing parts.”

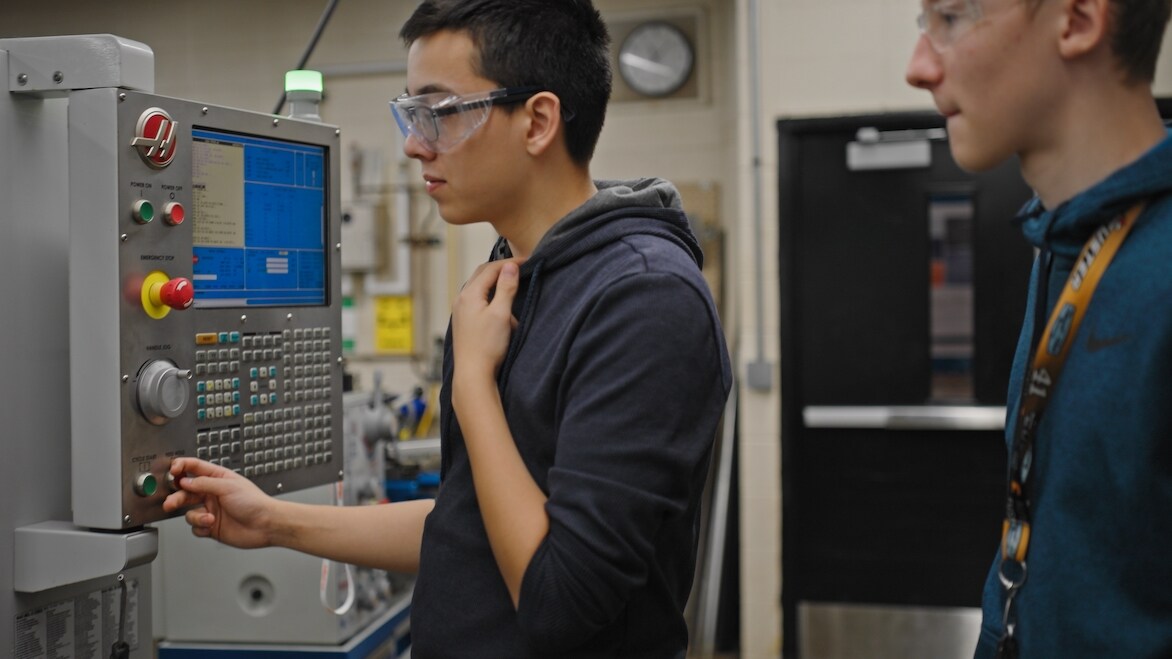

Streamwood High School precision manufacturing students get a jump on the work world with both CAD and CAM skills.

Making precision professionals

Within the discipline of precision manufacturing, students have to create parts to be accurate to within a few hundredths of a millimeter or a few thousandths of an inch. At Streamwood, the students learn the basics of computer numeric programming (CNC), milling, lathe operations, and quality control and then leave with enough skills to go straight into good jobs that provide a pathway to the middle class, according to Erbach. Streamwood maintains an industry advisory board for its precision manufacturing program full of small- and medium-sized companies, which frequently hire graduates right out of the school.

Nathan Padgett with one of his manufactured parts.

Focus on skills

“Students I have right now are some of the best I've ever seen,” Erbach says. “I currently have the only student who's ever taken on the SkillsUSA 5-axis CNC challenge, and he did so using Fusion 360. Some of the students in my room have more hours on a 5-axis machine than I do.”

For example, one of Erbach’s students, Nathan Padgett, wants to pursue a career as a machinist after high school. “Fusion 360 has opened my eyes to a new way of manufacturing,” he says. “It lets me use my creativity to make anything I want, and it also lets me use my engineering skills to pursue that. I thought I would have to take a super-long class for it, but come to find out that it’s actually very easy to use for a new person.”

Noe Diaz shows a soap mold he made with a dragon design.

Head start on the machine shop

Another current student, Noe Diaz, would like to work in precision manufacturing after graduation, doing “something complicated” like mold-making. Diaz really appreciates the simulation features in Fusion 360 and says the software was easier to use than he expected and will help him in his professional life. “A year or two ago when I didn't know about Fusion, if I just got a job, I'd have to start from zero. Now that I know about Fusion, and I've had a few years of it, running a job is going to be a lot easier.”

Classroom as crucible

In preparing his Streamwood students for life after school, Erbach tries to bring the real world into the classroom. That may include conducting mock job interviews with members of the advisory board or teaching teamwork by collaborating with educational institutions across the world to make a single product. By combining professional CAD with complex multi-axis CAM programming in a single software available from a web browser, Fusion 360 helps instructors like Erbach teach both foundational and advanced design and manufacturing skills from one platform.

As a result, students are becoming more proficient than ever at going from concept to design to tooling and manufacturing, all before graduating high school. “It's really fulfilling to see them just taking ideas that pass through their head that they're actually building in real life,” Erbach says. “They're very, very good at what they do.”

Get free educational access to Fusion 360 software, learning content, and other resources.