NOX INNOVATIONS

How virtual design and construction created a new pipeline of talent

MEP SUCCESS STORY

Share this story

Bridging the gap between skills shortages and business growth of virtual design and construction

Nox Innovations, an electrical virtual design and construction (VDC) and fabrications service company, is revolutionizing the field of prefabrication and installation within the electrical construction sector. Their pioneering methodology not only tackles the persistent labor and skills scarcity on project sites, but has also given rise to a fresh challenge to source adept virtual construction engineers. In response, the company has developed an innovative training program designed to equip entry-level personnel with the expertise needed to jumpstart production using Autodesk software. And it’s all accomplished within an impressively short timeframe of just 90 days.

Courtesy of Nox Innovations

Going all in with BIM

Building information modeling (BIM) isn't just a checkbox for Nox Innovations. It's a strategic advantage in a competitive landscape. As a dedicated provider of electrical VDC and fabrication, Nox Innovations has woven BIM into the very fabric of its operations.

Catering to the VDC and fabrication needs of Corbins and a host of other enterprises, Nox Innovations has anchored its electrical construction service business firmly upon the principles of BIM-to-fabrication. The company's trajectory began to diverge from Corbins in 2017 when their innovative approach to fabricate electrical model content began attracting attention from other electrical contractors across the United States. Almost every project Nox Innovations takes on requires BIM because of their design, prefabrication, and installation process that increases speed and reduces cost and waste.

"We're one of very few contractors out there that actually models all their content down to even half-inch conduit, which is unique when it comes to industry standards."

—Tony Anderson, Innovations Specialist, Nox Innovations

Example of Nox Innovations' prefabricated kit ready for delivery and installation. Courtesy of Nox Innovations.

Creating a new workflow and prefabrication for electrical installations

Nox Innovations' prefabrication and installations are different from what you might typically expect. Imagine an IKEA-style kit delivered on one pallet ready to install on site. Yet, what sets this apart is an upgrade in guidance that ensures a seamless assembly process. This plug-and-play model not only curtails the need for extensive field support during installation, but also contributes to a heightened level of on-site efficiency.

"With our workflow, we can create a kit of parts that is fabricated here in our shop and then delivered for just-in-time installation," says Tony Anderson, innovations specialist, Nox Innovations. "We fabricate everything from our models so there’s no bending or cutting on site. It also reduces the skilled labor we need on the job site because it's coming out as an assembly that you can put together easily. On average, the Corbins team saves about 10-15% in labor hours.”

"BIM has significantly amplified our fabrication capabilities. As an electrical fabricator that fabricates 80-90% of the modeled content, BIM plays a crucial role in our fabrication processes. We utilize the detailed information within the BIM model to generate fabrication-ready drawings and installation instructions. This seamless transfer of data to our fabrication shop enhances precision, reduces material waste, and expedites the assembly and installation of our electrical systems on-site."

—Tony Anderson, Innovations Specialist, Nox Innovations

Scaling for growth and workforce skills

Nox Innovations' distinctive process and BIM-centric workflow have their origins in the persistent challenges posed by labor and skilled workforce shortages, which have long plagued the construction sector. By adopting and integrating Autodesk AEC Collection, Autodesk Revit, Autodesk Navisworks Manage, Autodesk BIM Collaborate Pro, Autodesk Construction Cloud, Autodesk Build, Autodesk Docs, and the MEP toolset included with Autodesk AutoCAD, they could build an entirely new business model and reprioritize labor needs that easily cascade to all their projects.

Nox Innovations has helped mitigate the skilled labor shortage for their business, thanks to the simplified installation and their innovative design-fabrication-field process. But this can only happen with modeling in BIM—which can also be difficult to find qualified employees to do.

Since Nox Innovations is fully integrated with Autodesk solutions across their entire business, Anderson turned to the source of Autodesk truth: Autodesk University. It was there he first started to formulate the idea to build and scale a program to combat their talent shortage.

"I went to Autodesk University quite a few times and took classes there on creating training," Anderson says. “It sparked the thought that we needed to create our own."

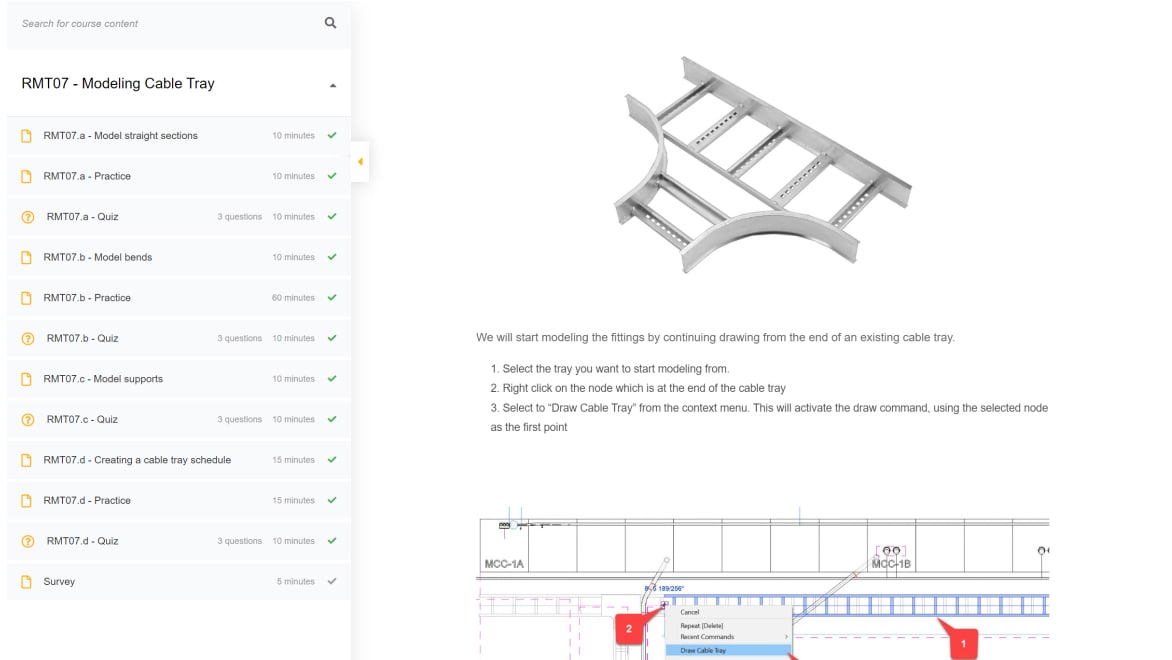

Example of NVCU training. Courtesy of Nox Innovations.

Establishing Nox Virtual Construction University

Nox Innovations officially started its training program a few years ago to develop their own talent and workforce. Since 2021 alone, there have been 112 participants and 106 graduates of Nox Virtual Construction University (NVCU) with more graduating each month. Individuals participating in the program come from a variety of backgrounds, from interior designers to video game designers and even Black Hawk pilots. They are all wanting and willing to learn the VDC skillset and move into a career in construction.

During the 90-day training program for virtual construction engineer positions, the company helps the entry-level employees become proficient in Revit, Navisworks, and Bluebeam and learn Nox’s workflow in a hands-on, instructional way. Everyone starts out working in Autodesk Construction Cloud from the get-go. The first 45 days are in the classroom with online training developed in-house followed by 45 days of “on the job” real-world experience and a final evaluation.

Revit model. Courtesy of Nox Innovations.

Building a strong curriculum for success

NVCU curriculum includes a wide range of topics geared toward electrical installation, from basic training of using Revit and Navisworks to sheet sets, fabrication shop drawings, and Nox’s own proprietary workflow. The training consists of 38 courses with 162 lessons that are set up in three stages spanning across the first 90 days of employment. Quizzes and one-to-one check-ins help Anderson and his team keep track of each student’s success and see where they may need more support.

"Once they complete the training, they'll be part of a team that develops the models for all the projects that we’re working on," Anderson says. "As they grow and learn more, there are even more opportunities to move on to become a project coordinator or manager and manage multiple projects."

Viewing success from a NVCU graduate’s perspective

After graduating from the University of South Carolina with a mechanical engineering degree last summer, Grace Mullen began applying for jobs, including a position at Nox Innovations. The company interviewed her, and she was soon moving west to begin her training to become a virtual construction engineer. "Ironically, electrical engineering was my least favorite subject in college," she says.

When she arrived for her first day, she admits it was a little intimidating when walking through the halls and seeing all the computers and models on the monitors. "It looked so hard and complex," she says.

With some encouragement from her mom, Mullen dove headfirst into the training. With only some limited work in CAD prior to joining Nox Innovations, she attributes the hands-on nature of the training to learning Revit and Navisworks faster than she expected. Working on a former project also made the work become real.

Once Mullen graduated from NVCU, she was immediately placed as a virtual construction engineer on a project. She credits the project manager for providing even further mentorship and an opportunity to become the lead on a project for a time. Along with the training, the culture of the company is driving her success.

"I give so much credit to my co-workers that I work with and my mentors that I have worked under," she says. "You can have a great training program. But without those people who want you to succeed, you’re never going to see success."

See related products

-

Powerful BIM and CAD tools for designers, engineers, and contractors, including Revit, AutoCAD, Civil 3D, Autodesk Forma, and more

-

Cloud-based design co-authoring, collaboration, and coordination software for architecture, engineering, and construction teams. “Pro” enables anytime, anywhere collaboration in Revit, Civil 3D, and AutoCAD Plant 3D.

-

Comprehensive field and project management software that delivers a broad, deep, and connected set of tools for builders.

Learn more